AT&T service trucks play a pivotal role in emergency response, especially in disaster-stricken areas like during the Los Angeles wildfires. Equipped with cutting-edge technology, these trucks ensure that first responders maintain communication in the most challenging conditions. In the following chapters, we will explore the critical components of these trucks, starting with their sophisticated satellite communication systems, moving on to their mobile cell site capabilities, reviewing their robust power generation systems, and concluding with the emergency response tools that support technicians on the ground. Understanding these elements highlights the vital role technology plays in restoring service and safety during crises.

Inside the Mobile Service Truck: Satellites, Cells, and the Power to Reconnect

When a crisis arrives and the usual channels of communication falter, a mobile service truck rolls onto the scene like a quiet, stubborn lifeline. It is more than a vehicle; it is a compact, highly engineered nerve center designed to restore sight and sound to a landscape that has suddenly gone dark. In the waning light of a wildfire or the chaos after a flood, residents hunger for basic contact, emergency crews need precise coordination, and journalists or public health teams seek a steady stream of information. The truck’s purpose crystallizes in that moment: to reweave the fabric of connectivity where it has frayed or torn. Inside, the chassis is packed with purpose-built hardware that serves two master aims at once. The first is resilience—systems that keep talking even when power grids fail or towers become unreliable. The second is speed—tools and protocols that let technicians establish a functioning network, diagnose faults, and field-restore services while the situation on the ground continues to evolve. The scene inside this vehicle is a blend of rugged practicality and high-tech sophistication, and it unfolds in a steady, almost methodical rhythm that mirrors the careful choreography of disaster response itself.

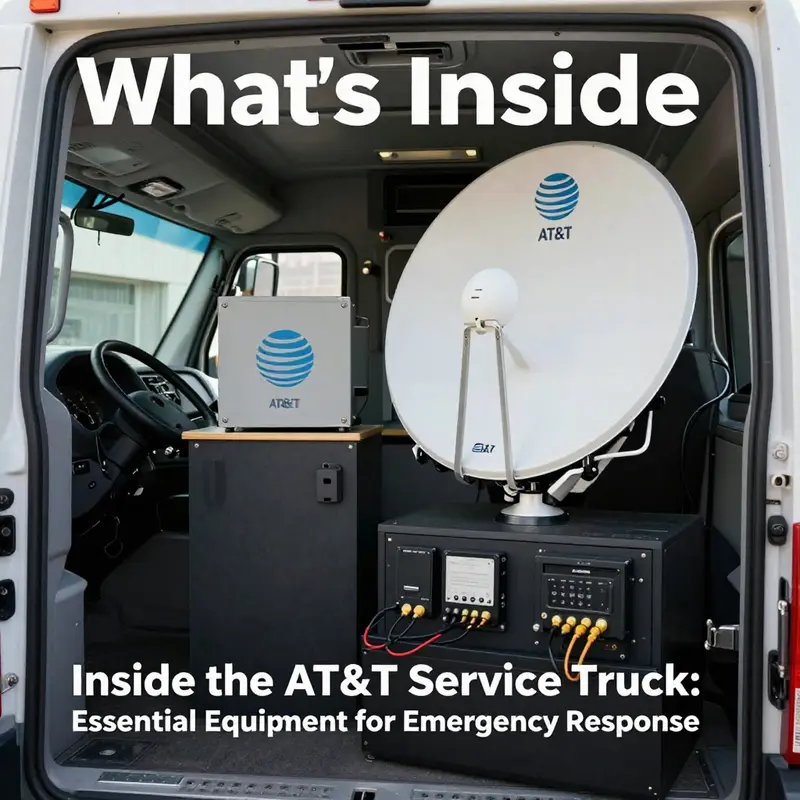

At the heart of the truck’s mission is satellite communication equipment. A high-gain terminal, typically housed in a stabilized, weatherproof dome, points toward a network of satellites above the globe. This dish is not just a curious antenna; it is a gateway to a network that remains intact when terrestrial infrastructure collapses. The satellite modem that sits alongside it translates waves of data into usable traffic—voice, data, and video—so field teams can talk to each other, to headquarters, and to support centers that are miles away. In practice, this means a live teleconference with command staff, a real-time map of field operations lighting up on a shared screen, and the ability to push updates to field devices almost as quickly as a responder can describe a developing incident. The quality of service depends on a chain of reliability: the dish tracks automatically, the modems negotiate with the satellite link, and the carrier-grade equipment maintains IP sessions across the air—an invisible but unwavering thread that stitches together the day’s work from a single, mobile platform.

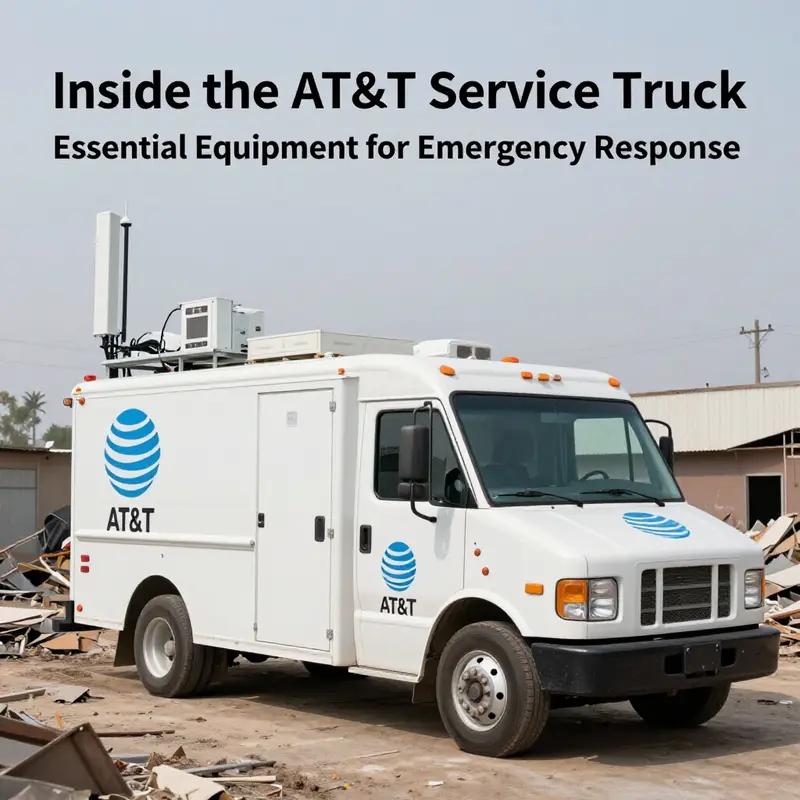

Yet the truck does not rest on a satellite link alone. It doubles as a mobile cell site, a temporary base station that can beam radio access to the surrounding area where cellular towers have either burned, toppled, or become overwhelmed by a surge of users. In concert with the SATCOM capability, the cell-on-wheels element creates a hybrid network that blends satellite backhaul with terrestrial wireless access. When a fiber cut or power outage disables a fixed site, this hybrid approach reestablishes coverage over a broad swath of terrain. The base station hardware inside the vehicle is purpose-built to withstand dust, heat, and rough terrain, yet it remains pliant enough to reconfigure as needs shift. Technician dashboards display the status of each sector, indicating which frequencies are in use, how many user devices are connected, and where the most critical voice and data flows are happening. In the field, every logged connection is more than a signal; it becomes a link that can carry a dispatcher’s orders, a nurse’s patient information, or a family calling to confirm that everyone is safe.

Power is the quiet imperative that undergirds all of this. The truck’s electrical backbone relies on robust, redundant power sources, because there is no room for guesswork when lives and livelihoods depend on connectivity. Large diesel generators, calibrated for continuous duty, deliver dependable energy to keep the SATCOM gear, the base stations, cooling systems, and the diagnostic tools running around the clock. Battery banks provide a cushion that smoothes out momentary fluctuations or brief outages. The design emphasizes redundancy: more than one power path feeds critical components, and critical components are duplicated so a single failure does not cascade into a wider communications blackout. In practice, that means the technicians can keep the network alive through long nights, heavy weather, and shifts that demand endurance as much as expertise. The sound of fans, the glow of status indicators, and the faint hum of cooling units set a familiar, almost comforting rhythm—an assurance that, even in a disrupted landscape, the means to talk, monitor, and respond persist.

The backhaul and core-network access come next in the truck’s operational narrative. Temporary backhaul devices bridge the local, on-site network with a broader core network, linking field data to remote control centers and cloud-based management tools. This is not mere scaffolding; it is the backbone that carries mission-critical information: the live photo from a street corner, the telemetry from a water pump station, the command to redirect traffic around a hazard. The backhaul hardware is designed to be modular and rapidly deployable, capable of re-routing traffic if a channel becomes congested or if a partial collapse of infrastructure requires an alternate path. In the same breath, the network-management systems onboard perform continuous health checks. They monitor packet loss, jitter, and latency, and they can reconfigure routes on the fly to preserve a clean, actionable data stream. The goal is not merely to restore communication in a vacuum but to ensure that the restored lines of contact stay stable as the scene on the ground shifts, whoops of gusts, ember plumes, or sudden rainfall alter accessibility and safety conditions.

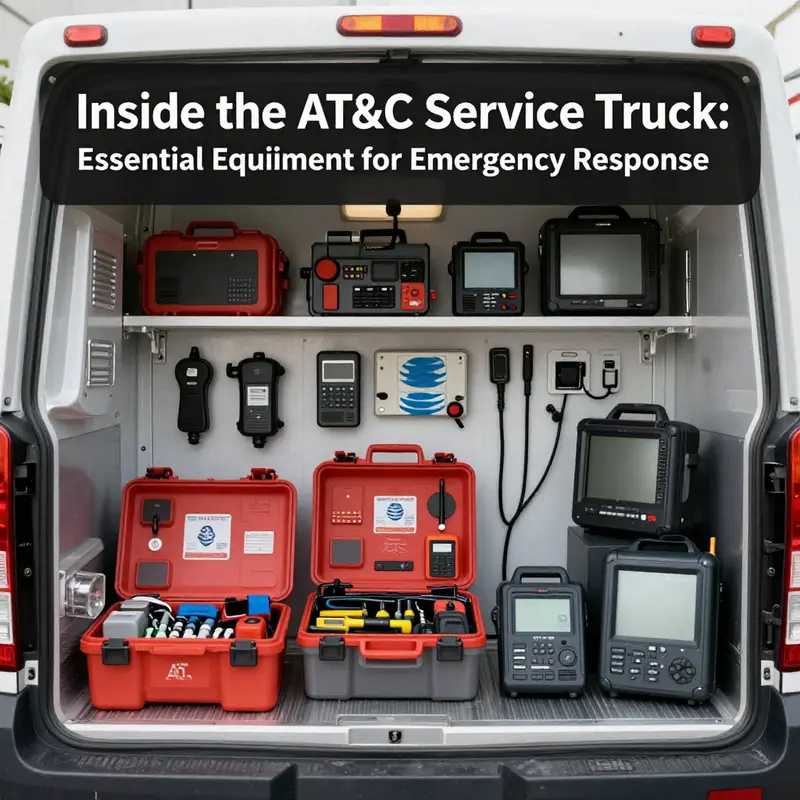

To make all of this possible, the truck houses an array of on-board tools and interfaces that technicians use to troubleshoot, deploy, and validate the network’s performance. A compact but capable suite of diagnostic hardware enables fiber and copper continuity tests, power-supply checks, and environmental monitoring. Spare parts—cables, connectors, splicing kits, fuses, and replacement components—are stored in weather-sealed bins to withstand the rough and tumble of field operations. The technicians move with a deliberate calm, guided by well-honed procedures that balance speed with safety. They run a sequence of tests to confirm that voice channels are clear, video feeds are steady, and data packets reach their destinations without unnecessary delay. The work is a careful blend of art and science: it requires a deep understanding of radio frequencies, network topologies, and the behaviors of equipment under adverse conditions, as well as the ability to improvise when a wrench or a connector refuses to cooperate.

Another layer of capability resides in the professional-grade management and monitoring tools that occupy a central console in the truck. These tools give technicians a real-time window into the health of the network, letting them see which devices are online, how much bandwidth is allocated to different services, and where congestion is likely to occur next. The monitoring software can highlight anomalies, predict potential failures, and even push over-the-air updates to field units when a new firmware or configuration needs to be deployed. In practice, this translates to fewer on-site maintenance calls and quicker restoration times, both of which are crucial when disaster response is time-sensitive. Because the vehicle can span a wide geographic area, a single operator wearing multiple hats—communications technician, network administrator, and field liaison—can coordinate a mesh of devices with a dashboard that speaks a common language of status, alarms, and performance metrics. The human element remains essential; the most advanced tools function only when someone with the right training reads the signals they emit and makes decisions that optimize the flow of information in the field.

The truck’s internal workflow reflects a philosophy of readiness and adaptability. Equipment is mounted in secure, shock-absorbing housings that keep sensitive electronics safe from sudden jolts or vibrations when traversing rough roads. The interior layout is organized to reduce switching between tasks: a shared workspace, a pair of ergonomic chairs, and a clear line of sight to the main display panels. The design minimizes fatigue and fosters quick, precise action when circumstances demand speed. In practice, that means a crew can set up a functional satellite link in a matter of minutes, bring online the mobile cell site, and begin routing traffic through the temporary backhaul with a level of control that would have seemed like science fiction not long ago. The effect is a fusion of portable power and permanent-leaning capability—the sense that, for as long as the truck is on the scene, the network behaves with a steadiness and reliability that many communities have come to expect from their everyday communications infrastructure.

The narrative of the inside of a mobile service truck would be incomplete without acknowledging the roles played by the people who operate it. Technicians bring deep expertise in radio systems, IP networking, and field diagnostics, but they also cultivate a patient, methodical approach that is essential when every decision can ripple through dozens of response efforts. They must be able to translate a technician’s technical language into actionable information for incident commanders, public health staff, and other responders who rely on timely updates. They also need to be proficient in coordinating with other emergency services, so the truck can serve as a bridge between disparate teams that might use different radios, different data formats, or different protocols for sharing critical information. This human-centric dimension—communication, coordination, collaboration—ensures that the hardware’s promise becomes real in the midst of chaos. It is not enough to have the most powerful satellite terminal or the most expansive backhaul; the success of the mission rests on how well people use those tools together under pressure.

In practice, the truck’s capabilities shape how communities perceive and experience resilience in the wake of disaster. When families hear a voice on the other end of a line and receive updates about shelter locations or medical aid, they feel a thread of continuity. When first responders receive a stable map view and a dependable data feed, their situational awareness quickens, their decisions become more precise, and risks can be mitigated. When school districts arrange remote attendance through video and voice channels, or when clinics coordinate stock and patient information, the technology ceases to be abstract and becomes a practical enabler of recovery. The vehicle’s satellite link keeps conversations flowing across the region even as local towers struggle to recover, while the mobile cell site restores local cellular access for many communities, bridging the gap between distant command centers and the street-level needs of people trying to contact loved ones, access services, or request assistance. The result is not merely restored connectivity; it is a restored sense of control and normalcy that can help communities endure the immediate crisis and begin planning for longer-term recovery.

As with any complex, high-stakes system, the design and operation of the mobile service truck rests on principles of efficiency and reliability. Designers and operators strive to keep the footprint manageable while expanding capability, so a single vehicle can function as a flexible, scalable node in a larger network of mobile and fixed resources. This is where the literature on emergency service design echoes in practice: the best solutions are those that balance performance with ease of use, and that can be deployed quickly without compromising safety or quality. For readers seeking a deeper dive into the design philosophy that guides such emergency platforms, a detailed discussion on design efficiency in emergency services offers valuable context. The link below provides a concise overview of how thoughtful design translates into tangible operational benefits in the field. design-efficiency-in-emergency-services

The integration of satellite capabilities with a mobile cellular base station, supported by robust power, backhaul, and monitoring, creates a resilient, responsive system that can adapt to the unpredictable rhythms of disaster response. The chapter you have just read sketches the outline of what makes these trucks invaluable: a carefully orchestrated stack of hardware that can pivot from a repair-oriented mission—splicing fiber, replacing damaged cables, testing continuity—to a full-scale communication relay that reconnects families, responders, and service providers. It is a reminder that the infrastructure we rely on in peacetime is not born fully formed for crisis; it is field-tested, modular, and designed to be deployed in moments of need. The technicians who operate these vehicles embody that ethos, turning sophisticated equipment into practical, on-the-ground capacity that translates into safer streets, steadier information flows, and a more certain anchor for communities as they navigate the uncertainties of emergency events.

For readers who want to situate this description within a broader landscape of emergency response resources, the following external reference provides additional perspective on the topic of mobile network solutions and their deployment in field operations. External resource: https://www.att.com/business/solutions/mobile-networks.html

Inside the Mobile Cell Site: How a Crisis-Response Truck Rebuilds Connectivity on Wheels

On the edge of a smoke-choked street, a service truck rolls into a crescent of space cleared by responders. It looks like a rugged transport, but within its chassis lies a compact, mission-ready data center. This is the mobile cell site, a cell-on-wheels, a device designed to bend the rule that networks fall apart when towers fail. When wildfires, floods, or earthquakes strike, this truck does not merely transport equipment; it broadcasts a lifeline. Its job is simple in description and exacting in practice: restore voice, data, and video services where they are most needed, and do so with speed, reliability, and orchestration. The crew arrives with a plan, a toolbox, and a signal that a network can be rebuilt from spare parts, clever geometry, and shared standards. The truck carries the pieces that become a new cellular microcosm, bridging the gap between the ground and the core network, between responders in the field and the rest of the world.

Inside the cabin, the layout mirrors a small command center. High-power radio equipment sits behind rugged panels. The equipment is multi-band, supporting the range of frequencies used by voice and data services. A single install can support thousands of users across a wide footprint, enough to keep fire lines, dispatch, and families in contact as operations unfold. The radio gear is designed for rapid configuration: technicians select bands, set transmit power, and tune coverage with remote dashboards. The emphasis is on resilience as much as speed, so components are chosen for tolerance to heat, dust, and jostling in the back of a moving city. The truck’s design borrows from data-center principles: modular racks, hot-swappable boards, and robust shielding to minimize interference from engine noise and the city’s own RF clutter. The result is a surprisingly quiet, controlled environment inside a vehicle that has to endure the weather and the pace of crisis.

One of the defining features is the telescoping mast—the extendable tower that can rise when the truck is on site. This is not a mere antenna; it is a platform for capacity. The mast can extend to about 100 feet, and in some configurations even higher, enabling the base stations to reach beyond immediate rubble and into the smoke-gray skyline. Raising the mast is both a mechanical achievement and a signal strategy: height improves line-of-sight, reduces interference from obstacles, and creates a fresh signal contour that can blanket a stadium, a neighborhood, or a temporary evacuation route. The deployment crew coordinates wind, load, and safety concerns as they raise the tower, often with the help of stabilizing outriggers that anchor the vehicle to the ground. Once the mast is up, the base stations take their places in the field, and a new layer of coverage begins to form.

Power is the quiet backbone of the operation. A mobile cell site cannot rely on the local grid when infrastructure has been compromised, so it carries robust power systems. Generators supply clean, sustained electricity to the radio racks, the backhaul links, and the cooling systems that keep the electronics from overheating. Battery backups provide a buffer for short outages, ensuring continuity during brief fuel gaps or maintenance pauses. The power architecture is designed with redundancy in mind: an alternate generator can be engaged, or a battery string can take over, so that critical services do not flicker. This is not just about keeping the lights on; it is about guaranteeing a steady flow of information to first responders who rely on continuous streams of voice and data to coordinate search-and-rescue, triage, and crowd management.

Connectivity does not rest on a single path. In a disaster zone, the truck links to AT&T’s core network through multiple paths. The backbone comes in through fiber or wireless backhaul, forming a bridge between the mobile site and the broader network. The design prioritizes redundancy: if one backhaul link fails, another carries the traffic, preserving ongoing communications for dispatchers, incident command, and field teams. In addition to the terrestrial backhaul, the truck can leverage satellite links when necessary. Satellite communications provide a direct path to the network backbone even when ground infrastructure is compromised or destroyed. This dual-mode approach—fiber/air backhaul plus satellite fallback—creates a resilient network fabric that can adapt as conditions change on the ground. The result is more than a temporary boost in capacity; it is a controlled re-creation of a service area, tailored to the size of the response and the urgency of the moment.

Cooling and climate control sit at the intersection of reliability and longevity. In a desert city or in a charred field, the temperature inside the equipment racks would rise quickly without proper climate control. The COW includes dedicated cooling systems that circulate air through the equipment corridors, maintaining temperatures within the range the radios and processors expect. A stable environment reduces the risk of thermal throttling, equipment failure, and unplanned downtime. The air handlers and filtration systems keep dust and debris at bay, which is particularly important in wildfire zones and in construction zones where particulates swirl through the air. The result is equipment that can operate around the clock, rain or shine, with emissions controlled and noise kept to acceptable levels so that it does not become a distraction in tense moments.

In practice, the mobile cell site operates as a small, configurable network within a larger system. The base stations are designed to handle multiple frequency bands, enabling both legacy voice services and modern data traffic, including high-bandwidth applications. This capacity matters not only for the thousands of people who might be in a single neighborhood but also for the coordination flows of responders who need maps, uplink video feeds, and real-time situational data. The operator can allocate spectrum like a conductor assigns sections to musicians, balancing coverage and capacity to minimize congestion during peak activity. The design emphasizes rapid reconfiguration: if a blockage or interference arises, technicians can adjust antenna tilts, rebind frequencies, or re-route traffic with minimal disruption. The result is a resilient canvas of signals that can adapt to a changing physical landscape, whether roads are blocked, shelters are crowded, or new incident command posts emerge.

The people behind the hardware bring the system to life. A COW crew comprises radio technicians, electrical engineers, and field technicians who understand both the science of radio propagation and the practicalities of working in dangerous or unstable environments. They plan the footprint, determine the necessary tower height, and map the backhaul routes with the same care one would apply to a major temporary construction project. They also carry spare parts, splicing kits for fiber, and diagnostic tools that can verify link integrity, fiber continuity, and the health of the power system. When a trunk line is damaged or a splice fails, the crew can replace it on site, minimizing downtime. This capability turns a mobile unit into a temporary but robust extension of the fixed network, a seamless bridge that keeps lines open between on-scene responders and the outside world. The crew’s training emphasizes safety, efficiency, and coordination with public-safety teams, ensuring that the truck enhances the incident response rather than complicating it.

This approach to disaster recovery is not simply about replacing a tower or broadcasting more signals. It represents a philosophy of service continuity that has grown from lessons learned during major events and long-range planning for network resilience. The mobile cell site is designed to be deployed quickly, scaled according to the needs of the moment, and retired gracefully when the regular network is restored. The footprint of a single COW can be adjusted by adding or removing base stations, by reconfiguring backhaul paths, and by altering the mast height as the situation evolves. In larger events, multiple COWs can be coordinated to blanket a broader area, providing overlapping coverage and a multi-point backhaul that reduces single points of failure. All of these design decisions reflect a careful balancing act: you want enough capacity to relieve congestion and sustain critical operations, but you also want to keep the system simple enough to deploy rapidly and maintain in the field.

In the grand scheme, the mobile cell site is part of an integrated strategy for crisis response and network resilience. It aligns with the broader goal of keeping people connected when the stakes are highest. It is a reminder that behind every crisis, there is a chain of technologies that must be ready to spring into action. The vehicle is more than a warehouse on wheels; it is a carefully engineered platform where hardware, software, and human judgment converge. The pacing of deployment matters, as does the clarity of the plan. The crew must decide quickly whether to deploy a single mast or a multi-mast configuration, whether to lean on satellite backhaul, or to rely primarily on fiber links, all while ensuring that voice and data remain stable for incident commanders, responders, and affected residents. The mobile cell site demonstrates how network design principles translate into real-world reliability when humans are counting on it.

For readers who want to understand the design ethos behind these units, the conversation often returns to principles of efficiency, scalability, and interoperability. The approach emphasizes modularity, so that components can be swapped or upgraded without overhauling the entire system. It emphasizes standard interfaces, so equipment from different vendors can interoperate. It emphasizes rapid testing and verification, so what goes up in the field has already proven itself in a controlled setting. This is where the idea of design efficiency in emergency services comes into play, bridging the gap between classroom theory and field reality. design efficiency in emergency services. The link points to broader industry discussions about how mobile units are planned, deployed, and sustained over time, and it anchors the chapter in a wider conversation about resilience.

Ultimately, what makes a mobile cell site compelling is not only its technical sophistication but its ability to function as an extension of the human network it serves. In a crisis, the person on the radio with the dispatcher’s voice can hear colleagues across the scene with clarity. The map on the operator’s screen is updated in near real time, guiding responders along the safest route. The video feed from a drone or a field camera can provide crucial context to command decisions. And the voice calls between hospital triage teams and field units can continue without interruption, even as the city around them reels. The truck, the mast, the backhaul links, the cooling fans, and the racks of radios all work in concert to restore something that is precious and fragile: connection.

External resource: https://www.att.com

Power on the Move: Inside AT&T Service Trucks and the Machinery That Rebuilds Connectivity

When people think of a service vehicle rolling into a disaster zone, they often imagine a simple patchwork of cables and transformers. In truth, the vehicle is a carefully engineered mobile hub designed to be a self-contained node of resilience. The core idea behind an AT&T service truck, especially in emergency settings, is to create a resilient, adaptable, and brief but robust network-on-wheels. It carries a suite of systems that together form a temporary but dependable communications backbone. A core principle guides every choice inside the truck: power and connectivity must be available even when the ground infrastructure has failed, when weather has damaged lines, and when the clock is running against the clock of recovery. In these moments, the truck becomes more than a tool; it is a moving nerve center that coordinates voices, data, and visual feeds for first responders, technicians, and field command. The heart of that capability lies not only in the satellite and mobile cell equipment that broadcast signals, but in the power generation systems that keep those signals alive around the clock. Without power, the most sophisticated antennas and base stations are nothing more than metal and cables; with power, they become a living, breathing extension of the grid—one that can be deployed to restore the bare minimum of connectivity that relief efforts rely on to organize and save lives.

Central to the power story inside the truck is a layered approach to energy generation and storage, designed to cover a wide range of contingencies. High-capacity backup generators form the first line of defense. In practice, these are diesel or gasoline-powered units capable of delivering continuous electrical power for the network equipment, routers, and the base stations housed on board. The practical goal is straightforward: provide an uninterrupted feed so that the communication system remains online even as external power sources disappear or become unreliable. The design acknowledges the harsh realities of deployment. Fuel logistics can be as critical as the equipment itself during a long response, so redundancy is built in. Multiple generators can be staged so a single unit running low on fuel does not halt operations. In the field, switching between units is practiced as routine maintenance—an on-site safeguard that minimizes downtime and keeps the network humming while crews repair damaged lines or re-route traffic through satellite uplinks.

Battery systems represent a second, equally important, layer of resilience. Today’s service trucks deploy large-scale energy storage banks that can store energy from a running generator or from a grid when available. These banks are most often based on lithium-ion technology, chosen for their efficiency, high energy density, and tolerance for repeated charge-discharge cycles. The batteries provide an immediate power reservoir that smooths out transitions between power sources. If a generator experiences a hiccup or a temporary loss of fuel delivery, the battery bank can bridge the moment, maintaining critical services while the system rebalances. Battery storage also supports more nuanced energy management, allowing operators to run essential components at peak efficiency and scale down nonessential loads during tight power margins. In effect, the battery system turns a simple generator into a dynamic power plant that can ride through outages without creating abrupt service gaps.

To complement the heavy hardware, portable power units (PPUs) populate the fleet as agile, rapid-deploy options for interim or temporary sites. PPUs are compact, mobile, and quickly dispatched to a disaster zone or a newly established field command post. They can be pedestal-mounted or carried in auxiliary compartments and deliver an essential trickle of electricity to keep radios, consoles, and small routers functioning until more permanent power is reestablished or a larger generator is brought online. The PPUs are not a substitute for the larger generator, but they are an important multiplier of uptime during the most chaotic phases of a response. They enable technicians to lay the groundwork for a broader network restoration while larger power systems are being mobilized or repaired. The tactical use of PPUs reduces the risk that critical communication is interrupted during the crucial handover from field clearing to network restoration.

In recent iterations, some service trucks also incorporate solar hybrid systems as a way to augment the traditional power stack. Solar panels on the exterior canopy or roof surface contribute a renewable charge that can reduce fuel burn over the course of a shift and lessen the environmental footprint of a prolonged operation. The solar contribution is modest in energy terms, but it matters when the objective is to sustain high-priority communications without constantly refueling. The hybrid approach also supports longer deployments where fuel resupply becomes logistically challenging. The energy coming from the sun edits the calendar of the response—giving technicians more hours of operation between cycles of maintenance and refueling. It is not a silver bullet, but it is an important complement to the diesel or gasoline backbone, aligning with broader sustainability goals while driving practical uptime improvements in field conditions.

All of these components feed into a smart power management system that keeps the entire micro-grid within safe and efficient operating boundaries. Modern power management software continuously monitors voltage, current, temperature, and load. It choreographs when to run which generator, when to pull energy from the battery bank, and how to distribute power among the various subsystems that must stay live. The software considers the full spectrum of loads—the satellite uplink chain, the mobile base station equipment, network routers, diagnostic tools, and even environmental control devices that protect sensitive electronics in a harsh field environment. By balancing supply and demand in real time, the system prevents overloads, extends generator life, and minimizes fuel consumption. It also elevates safety by providing visibility into any abnormal readings that could indicate a fault, enabling technicians to intervene before a problem becomes an outage.

The practical result of this multi-layered energy strategy is a truck that can function as a self-contained cell site and satellite gateway in some of the most challenging environments. The technicians who operate these vehicles are trained not only in telecommunications repair and deployment but also in energy literacy—the ability to read a power schematic, understand the interplay between different energy sources, and anticipate how a sudden shift in weather or terrain could affect fueling and charging. In the field, this translates into a disciplined routine of checks and rehearsals. A typical day might begin with a quick audit of generator readiness, fuel levels, and battery charge. The crew then verifies the health of the solar system if present, confirms proper operation of the PPUs, and tests the smart management console that will govern the day’s energy budget. With the power architecture deemed healthy, technicians step through a sequence of system checks that confirm the satellite uplink and mobile broadcast chain are receiving stable power. The process is a careful choreography, not a one-off startup, because the network’s reliability depends on the continuity of energy just as much as the integrity of cables and antennas.

All of this power infrastructure sits inside a vehicle designed to endure rough conditions. The compartments are weatherproof and organized so that technicians can quickly locate spares, cables, and splicing kits when repairs are needed. Temperature control systems, vibration dampening, and ruggedized mounting points help protect delicate electronics from the shocks and vibrations of a rough road or a windy hillside. The goal is not simply to have power; it is to have predictable power that remains available under stress. In that sense, the truck embodies a philosophy of readiness: never rely on a single source of energy; always have back-up, wait-ready equipment, and a method to bridge any gap between power and service.

This robust energy architecture also intersects with the broader mission of disaster response. When a region loses its traditional communications fabric, people rely on field crews to reestablish lines of contact between responders, hospitals, shelters, and the public. The power generation systems inside the truck enable a chain of capability from the moment the unit arrives on site. The satellite uplink, powered by the generators and battery banks, can reconstitute voice and data channels that enable coordination among command posts, field crews, and utility repair teams. The mobile base station, powered by the same energy ecosystem, becomes a temporary cell site that can blanket a disaster zone with coverage large enough for rescue teams to operate effectively. The resilience of this arrangement does not merely reflect the sophistication of the hardware; it reflects a design mindset that prioritizes uptime, rapid deployment, and the practical realities of fieldwork—fuel logistics, weather, terrain, and the need to adapt to changing conditions on the ground.

From a maintenance perspective, the power systems require ongoing attention. Generators need regular service intervals, fuel filtration checks, and exhaust system inspections to ensure emissions remain within safe and legal limits while sustaining continuous operation. Battery banks demand thermal management and periodic capacity testing to confirm they can still deliver the required energy during an outage. Solar components must be kept clean and unencumbered by debris to maximize efficiency. The PPUs require readiness checks so that they can be deployed instantly when needed. Behind all of this is a culture of proactive maintenance—where pre-emptive checks, spare parts availability, and rapid diagnostics reduce the risk of unplanned downtime. The emphasis is on reliability so that, in the face of a crisis, the network is capable of supporting those who respond to it and the communities depending on its services.

The narrative of power inside the service truck also speaks to a broader, evolving approach to field telecommunications. The push toward hybrid energy solutions and smarter load management mirrors the industry’s shift toward more sustainable and resilient networks. It reflects an understanding that disaster response is not only about restoring a single link but about sustaining a cascade of critical services that ripple outward—from emergency communications to hospital coordination to public safety signaling. When a truck arrives, it does not merely plug into a fuse box and pretend the grid has returned. It provides a real, functioning micro-grid that can operate independently, adapt to shifts in demand, and scale up as more resources become available. In moments of extreme need, that capability becomes a tangible difference—the difference between a fragmented response and a coordinated, effective one.

For readers interested in the practical logistics of maintaining and upgrading these vehicles, there are rich resources that underline why robust maintenance and training are essential. Acknowledging the importance of hands-on preparation, one resource outlines why ongoing maintenance training for emergency apparatus matters so much—the kind of training that ensures crews can diagnose a failing power unit, reconfigure a power layout, or swap a critical component under pressure. The emphasis on maintenance readiness echoes throughout the field, reminding us that technologies only shine when people know how to use them, fix them, and integrate them into the larger operation. To explore that perspective further, see the dedicated guide on fire-truck maintenance training importance: fire-truck-maintenance-training-importance.

As these trucks continue to evolve, the development path points toward even smarter energy orchestration, with deeper integration between power systems, communications gear, and field automation. The overarching aim is simple in intention but complex in execution: to ensure that, no matter what happens to the power grid, the network needed by those delivering relief remains accessible. A single service vehicle can so often determine the speed at which information flows back to a central hub, helping to coordinate responders, allocate resources, and guide people to safety. And because power is the currency of connectivity, every watt saved or delivered with precision translates into faster restoration of voice, data, and video streams essential to crisis management. In that sense, the inside of the AT&T service truck reveals more than a collection of devices. It reveals a disciplined approach to resilience, a calculated balance between traditional power generation and modern storage, and a forward-looking mindset about how to sustain critical infrastructure when it matters most.

External resource for further reading on how these concepts play out in practice can be found at the official site of the broader communications provider focusing on emergency readiness and network operations: https://www.att.com

Inside AT&T Service Trucks: The Hidden Gear Powering Emergency Communications

When disaster strikes and the ground lies quiet under the weight of smoke, floodwaters, or debris, a steady procession of service trucks rolls into view. These vehicles are more than a collection of tools on wheels; they are mobile lifelines designed to restore and sustain communication when every other link buckles. In the heart of each AT&T service truck lies a carefully engineered ecosystem that blends satellite reach, temporary cellular capacity, robust power, and nimble repair capability. The goal is simple and urgent: reestablish a conduit for voice, data, and situational awareness between field responders and the people they serve. The result is a rolling command post that can adapt to rapidly changing conditions on the ground, a fleet of assets that can be deployed quickly, with precision and dignity, to knit back together a community frayed by crisis.

At the core of the truck is a satellite communications system. In many emergencies, terrestrial networks falter or fail entirely because towers are damaged, overloaded, or overwhelmed by demand. A SATCOM capability becomes the decisive bridge across those gaps. It provides a direct, backhaul connection to the wider network, allowing dispatchers to route calls, transfer data, and even stream video from the scene to command centers that may be hundreds of miles away. Even when fiber cuts sever local routes or when weather erodes the usual pathways, the satellite link remains a resilient backbone. Technicians rely on this link not merely for connectivity but for the assurance that the mission-critical data flowing back to engineers and decision-makers remains intact, timely, and actionable. The image of a service truck, antennas protruding into a smoky sky, evokes a literal tentpole of continuity: the line that keeps conversations going between frontline responders, medical teams, and families awaiting word.

Beside the SATCOM setup sits another robust component: a mobile cellular site that can be deployed as a temporary base station on wheels. This is not a small repeater hidden in a closet; it is a purpose-built platform that can broadcast a wide geographic footprint to provide emergency cellular coverage in areas where damaged infrastructure has left people isolated. By creating new macro-level coverage, the mobile cell site ensures that first responders can coordinate movements, confirm locations, and share critical situational data without the bottlenecks that often accompany overloaded networks in crisis zones. It also gives residents a lifeline for contacting loved ones, accessing emergency information, and receiving real-time alerts. The capacity and reach of these cellular units become especially vital in scenarios where schools, hospitals, and municipal centers—traditionally anchors of communication—are compromised. The effect is not merely technical; it is social: safety and reassurance emerge from the ability to connect, even when the physical world around a community seems to be unraveling.

Power is the quiet, unglamorous backbone that keeps all of this intentional design functioning. The service truck carries substantial diesel generators, chosen for endurance and reliability. In a disaster where the power grid falters for hours or days, these generators ensure that the SATCOM gear stays online, the base stations remain energized, and the diagnostic tools keep running. Battery banks and fuel management systems are staged for quick replenishment, with safety and efficiency at the forefront. Power resilience is not a luxury; it is a prerequisite for any meaningful restoration of service. When wind shifts or water rises, the generators keep lighting, keep CPUs spinning, and keep the air-calls steady, which, in turn, preserves the flow of critical information to those who need it most.

The equipment list inside the truck speaks to the hands-on realities of field work. Emergency response tools include fiber optic splicing kits, fusion splicers, and a full suite of cables and diagnostic instruments. These are the instruments of restoration, the devices technicians use to repair or re-route damaged networks on the spot. When a fiber line has been compromised, the crew doesn’t wait for a distant crew to travel in from a regional hub. They can rejoin the line, splice as needed, and re-energize segments of the network with precision. The presence of these tools in the vehicle underscores a philosophy of capability at scale: a single truck can perform the kind of localized repair that might otherwise require a make-shift field office and a longer wait for a central repair crew.

Inside the cabin and along the cargo area, technicians bring rugged laptops and mobile workstations that connect to an internal, secure network. Real-time data flows from the field into the network operations center, where engineers monitor performance, adapt configurations, and ticket outages as they appear. This setup supports an iterative, feedback-driven workflow. A technician can diagnose a problem, assign a task, and, in short order, reconfigure a base station, re-grant access to a satellite channel, or allocate additional spectrum where needs shift with the terrain of a crisis. The rugged devices are built to withstand dust, rain, and vibration, ensuring that a single setback—such as a jolt from a rough road or a sudden power drop—does not derail the mission.

Yet the material core is only part of the story. The human dimension—the teams who arrive, secure the site, and operate the equipment with discipline and care—completes the cycle. Safety gear and PPE are not decorative. They include hard hats, gloves, safety vests, and insulated tools designed for working near energized systems or at heights. The discipline of safety becomes especially important when the landscape is unpredictable: uneven ground, downed infrastructure, and unstable conditions demand a measured, professional approach. The equipment is formidable, but it is the trained technicians who wield it with restraint and foresight, turning a potential hazard into a controlled, safe operation that restores a vital service.

Communication devices are the thread that ties the entire operation together. Radios, satellite phones, and mobile hotspots ensure that teams in the field stay in contact, not just with each other but with the larger network of responders, dispatch, and engineers. Redundancy is a principle here: multiple channels ensure that if one path is compromised, another remains open. In a crisis, a minute of delay can translate into missed opportunities for coordination or slower recovery of essential services. The trucks are designed to minimize those delays by maintaining a culture of continuous contact, where every tool has a defined role and every signal matters.

In some deployments, the trunk of the truck may contain emergency medical kits and basic first-aid supplies. While not universal, this inclusion reflects a broader responsibility: the reality that in disaster zones, responders and technicians alike can face injuries or medical needs before professional care can arrive. The presence of a ready-to-go medical kit reinforces a practical, holistic approach to crisis management. It is another reminder that emergency response is not a single task but a spectrum of needs that an organized service fleet seeks to meet with speed and care.

The arrangement of these elements—satellite connectivity, mobile cellular capacity, robust power, field repair tools, diagnostic and testing equipment, rugged computing, PPE, and medical readiness—creates a unified system. Each piece reinforces the others. The satellite link may fail to deliver the last mile of coverage if the on-site base station cannot be powered, and the base station cannot function without the technicians who can install, configure, and repair it. The testing gear identifies issues with signal propagation or fiber integrity, guiding the crew toward the precise intervention that will make the next hour of traffic flow more reliable. The end result is not a collection of discrete tools but a cohesive machinery of resilience that scales with the challenge at hand. The truck becomes a portable hub that, in hours or days, can expand into a network backbone for a community struggling to regain normalcy.

This integrated approach also illustrates a broader design philosophy in emergency equipment. The layout emphasizes modularity and rapid redeployability: components can be swapped, upgraded, or reconfigured as demands shift across different incidents. A design such as this is not merely about surviving a single incident; it is about sustaining a networked footprint that can endure a prolonged response, support a growing surge in demand, and adapt to the changing geography of a disaster. For readers curious about how emergency-vehicle design translates into operational uptime and efficient field service, this topic is explored in depth elsewhere: design-efficiency-in-emergency-services. design-efficiency-in-emergency-services

The narrative of the service truck also highlights the hidden choreography of maintenance and readiness. The fleet must be kept at a state of nominal operation, a perpetual readiness that anticipates outages before they occur. Spare parts, diagnostic kits, and a careful inventory of splicing tools sit alongside the primary mission gear. The technicians’ readiness depends on a culture of ongoing training and attentive upkeep—an investment that pays off when the next outage is reported. In this sense, the service truck is less a single vehicle and more a mobile workshop, a compact, self-contained ecosystem that embodies a broader commitment to continuity. The technicians bring not only the gear but also a habit of disciplined, methodical work. They follow checklists, calibrate instruments, and perform regular tests to verify that each component will respond as needed when disaster strikes. The result is a level of reliability that communities can count on, even when the sky is dark and the streets are chaotic.

The significance of these trucks in the larger tapestry of disaster response cannot be overstated. They shorten the distance between a reported outage and a repaired network. They provide a platform for rapid diagnosis, dynamic reconfiguration, and real-time coordination that would be impossible with a static set of tools. They also symbolize a broader truth about modern communications: resilience is not just about having a robust core network; it is about how quickly and intelligently you can extend that network into the places where it is most needed. The service truck embodies that principle by turning a vehicle into a mobile extension of the network operations center, a rolling node that breathes life into the public safety grid when it would otherwise be inert.

In the end, what matters most is not the individual instruments or the sheer quantity of gear on board, but the capability to deliver reliable communication under pressure. The truck’s engineering, the technicians’ training, and the careful orchestration of satellite, cellular, and wireline resources coalesce into a force that sustains contact between responders, dispatchers, and civilians who rely on timely information. The effect is profound: when people look for guidance, reassurance, and help, they find it through a line of sight reestablished by a team of professionals who have designed, equipped, and positioned their tools to work in harmony at the very moment when harmony is needed most.

External resource: https://about.att.com/news/

Final thoughts

Understanding the intricate technology and equipment housed within AT&T service trucks sheds light on their crucial role during emergencies. From satellite communication systems that ensure voice and data connectivity to mobile cell sites that act as temporary towers, these trucks embody the spirit of reliability in crisis situations. Power generation systems keep everything running smoothly, while the array of emergency response tools equips first responders with the means to restore services swiftly. This technological synergy not only aids in communication restoration but also supports the essential work of first responders who rely on these systems to save lives and protect communities.