The service brake pedal in a truck is a crucial component that all truck drivers should thoroughly understand. This leftmost pedal is not just a simple mechanism; it plays a significant role in preventing accidents and ensuring safety on the road. Long-haul truck drivers, trucking company owners, fleet managers, and aspiring drivers need to be well-versed in how this pivotal pedal operates, its importance, and the maintenance required to keep it functional. The following chapters will delve into the intricacies of the service brake pedal—from its mechanical workings to its safety implications, comparative analyses across various truck models, and best practices for maintenance. By the end of this guide, readers will have a holistic understanding of the service brake pedal, empowering them to enhance their driving skills and fleet efficiency.

The Left-Foot Command: Exploring the Service Brake Pedal’s Place, Purpose, and Practical Care in Heavy Truck Operation

The service brake pedal is the primary tool a driver uses to slow a truck with confidence and control. In most heavy vehicles with manual or conventional cab layouts, this pedal is positioned so the driver can press it with the left foot while the right foot rests on the throttle or prepares for nuanced throttle control. This arrangement—left foot for the brake, right foot for acceleration—has become a standard in many trucks and heavy equipment because it supports a steady, deliberate deceleration without crowding the accelerator. In articulated models and other large configurations, the brake pedal is often found to the left of the accelerator on the cab floor, a placement that prioritizes predictable pedal travel and legibility of motion for the operator. While a few model variations exist, the guiding idea remains the same: brake control should be intuitive, immediate, and separate from the accelerator for smooth, controlled stopping that preserves traction and safety in demanding on-road and off-road conditions. The left-foot brake design reduces the chance of confusing throttle input during braking, which can occur if both pedals are operated by the same leg or if the driver must reach for a brake with the right foot while underway. The ergonomics of this setup are rooted in decades of field experience, where precise timing and consistent pressure on the service brakes translate directly into safer deceleration under diverse loads, slopes, and road surfaces. The service brake pedal is thus more than a simple input; it is a gateway to predictable deceleration, a feature that supports both routine driving and emergency maneuvers without requiring the driver to switch leg positions or rethink pedal choreography mid-stroke. In ordinary driving, the pedal’s travel is meant to be smooth and linear, allowing the operator to modulate braking with increasing or decreasing pressure as traffic evolves. In situations that demand rapid slowing, the same left-foot access becomes a reliable reflex, letting the driver apply full braking force promptly while the right foot continues to monitor speed and engine response. This separation of control minimizes missteps and can reduce reaction times in critical moments, which is essential for heavy vehicles that carry substantial mass and may need to respond quickly to hazards, weather changes, or sudden roadway incidents. The design is not solely about safety; it also supports efficiency and passenger comfort. A well-calibrated service brake pedal offers fine control at modest speeds, enabling smooth deceleration that preserves tire grip and steering stability. When the pedal is designed with a clear feel—an immediate response to light pressure that grows predictably with greater input—the operator can anticipate the braking force and maintain control through gentle downshifts or gradual reductions in speed. Even in the high-stakes realm of articulated trucks and other heavy-duty platforms, the principle of left-foot braking anchors the driver’s sense of rhythm and machine behavior, helping to synchronize braking with engine modulation, transmission gearing, and the vehicle’s braking system. The footwork is not an abstract idea; it translates into practical habits that form part of routine operator training. In practice, drivers learn to apply just enough pressure to begin deceleration, then modulate to a precise stop or a steady descent down a grade. The practice becomes more complex when terrain, load, or road conditions demand a staged approach to braking, yet the left-foot control remains a constant anchor. It is worth noting that hybrid and electric heavy trucks may incorporate integrated braking features that complement the service brake, using regenerative or automated braking to harvest energy and reduce wear. In those configurations, the service brake pedal still serves as the human override, the point where the driver intentionally intervenes to adjust the braking profile, especially when road conditions are changing or when precise stopping is required in tight spaces. For the operator, the reliability of the pedal—its physical feel, its return to rest, and its resistance characteristics—becomes part of the vehicle’s personality. Technicians assess the pedal’s travel, the response at various pressures, and any play along its path during routine inspections. The simplicity of this input belies the complexity of the system it governs. The service brake is not a single device but a gateway to a network of components: hydraulic or air lines, brake chambers, linings or pads, and the mechanical linkages that translate pedal movement into wheel force. In many heavy applications, the service brake works in concert with a broader braking system designed to withstand heavy loads and repeated use without compromising stopping power. The pedal is the starting point, but its effectiveness depends on the health of the entire braking chain, from fluid levels and lines to pads, rotors, and the pressure management system. When maintenance is neglected, the quiet confidence of left-foot braking can erode. Uneven pedal feel, excessive travel, or soft stops are early tells that something in the braking chain needs attention. Regular checks—fluid or air pressure stability, pad thickness, leak detection, and pedal alignment—keep the system honest and the operator confident. In training environments and practical field applications, instructors emphasize the habit of testing the pedal’s response in low-speed scenarios to confirm that the brakes engage smoothly and predictably. This habit translates into safer driving and more predictable handling, especially in congested urban routes where frequent stopping is necessary or in long downhill segments where sustained braking must cooperate with transmission control to prevent overspeeding and preserve engine health. The chapter’s focus on the pedal’s placement and function naturally links to the broader conversation about how braking systems are maintained and how operators interact with them under various conditions. For technicians and drivers alike, learning to read the pedal’s feedback—its initial bite, its progression, and its return to rest—provides essential clues about the health of the vehicle and the readiness of the braking system for the next stop. In the wider ecosystem of heavy trucking and emergency-service transport, the interplay between brake pedal ergonomics and system reliability becomes a shared baseline for safety, training, and ongoing maintenance. If a fleet manager asks how best to safeguard braking performance, the answer begins with a clear acknowledgment of the pedal’s role and an organized approach to inspection, testing, and calibration that honors the driver’s tactile cues as well as the machine’s mechanical needs. For readers curious about deeper technical specifics, the official articulated-truck braking systems documentation offers a comprehensive overview of how the service brake integrates with hydraulic or air circuits, how brake force is distributed under load, and how maintenance procedures support consistent performance. This resource can provide a technical framework for fleet owners and shop teams seeking to align practice with engineering expectations. Additionally, a practical link of interest to practitioners involved in multi-vehicle maintenance and operator training can be found in the fire-truck maintenance and service training materials, which discuss the hands-on aspects of brake inspection, pedal travel, and system testing in a relevant, high-use context. As with any complex vehicle, the art of braking in heavy trucks rests on a blend of intuitive pedal feel, disciplined maintenance, and an understanding of how all components work together when speed needs to be managed quickly and safely. The left-foot brake is more than a convention; it is a design principle that supports consistent, controlled deceleration across diverse driving scenarios. By paying attention to how the pedal behaves, how it is positioned, and how the entire braking chain responds, operators can keep their vehicles ready to stop on demand, protect the load, and preserve the safety of everyone on the road. For those seeking a deeper dive into the engineering specifics that govern how articulated braking systems are engineered and maintained, the external resource provides a detailed technical foundation that complements the practical guidance offered here. And for ongoing learning and practical application in related vehicle categories, see the referenced training materials and maintenance guides that connect the dots between pedal action, brake health, and safe operation on real-world routes. External resource: https://www.cat.com/en_US/products/trucks/articulated-trucks/understanding-articulated-truck-braking-systems.html

The Pedal That Commands the Stop: Inside the Service Brake System of Heavy Trucks

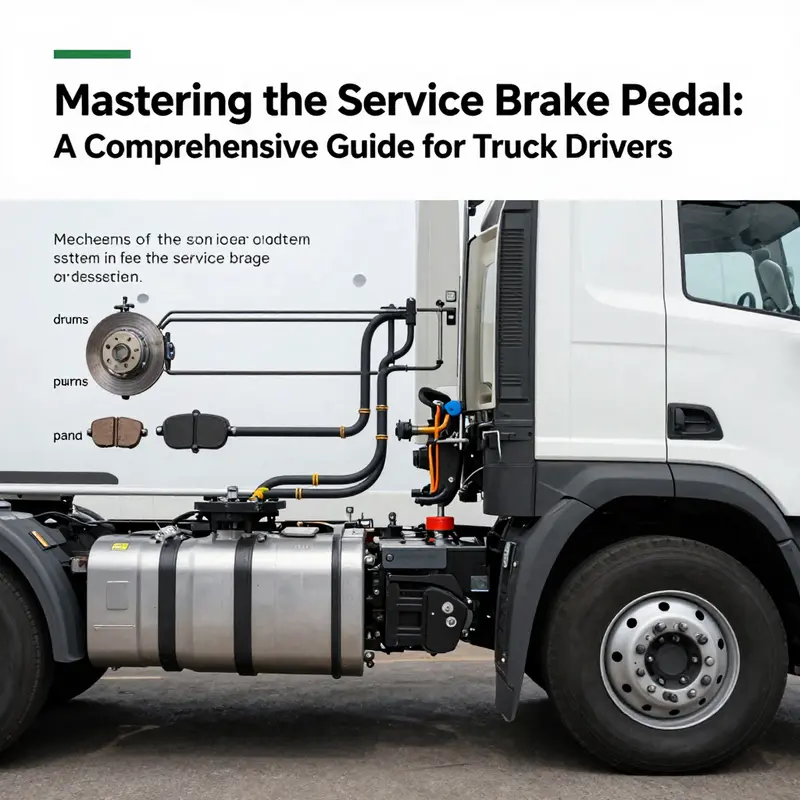

The service brake pedal is more than a simple interface for slowing a vehicle. It is the driver’s first and most consistent line of defense in bringing a heavy load to a controlled halt. In many traditional truck layouts, the pedal sits to the left of the accelerator, a placement that reflects decades of design intent to keep the driver’s foot aligned with the major braking force at the moment of need. Yet the exact position and feel can vary with different cab configurations and transmission setups. What remains constant is the function: depress the pedal, and a carefully engineered hydraulic chain of events translates foot pressure into wheel deceleration. When the driver presses down, a master cylinder converts the mechanical force into hydraulic pressure that travels through a dense network of brake lines. This pressure is what makes the calipers or wheel cylinders clamp the brake pads against the discs or drums, converting kinetic energy into heat and gradually reducing speed. The result is a smooth, linear response that a skilled operator relies on to modulate speed across a wide range of conditions, from a casual descent on a long grade to a sudden stop in heavy traffic.

The heart of the service braking system is hydraulic, a choice rooted in the need for consistent, scalable force transmission across multiple axles and varying load conditions. Unlike some lighter vehicles that may depend more on straightforward mechanical linkages, heavy trucks require a pressurized backbone that can deliver nearly instantaneous force to every wheel in proportion to the driver’s input. The brake system is a closed loop of precision. The pedal informs the master cylinder how much pressure to generate. The lines distribute that pressure to front and rear circuits, and often to multiple axles, with a balance calibrated to match weight distribution, tire grip, and road surface. In this steady chain of communication, the driver’s foot becomes the primary weather vane for braking demand, and the system translates that intent into measured deceleration.

The distribution of braking force is not uniform by accident. Front wheels often handle more stopping load due to weight transfer as speed is reduced, especially during threshold braking. However, an optimized system must also protect the rear wheels from lockup and compensate for dynamic forces during steering, acceleration, and cornering. In articulated trucks—where the vehicle is built with a jointed design to improve maneuverability—the braking system must respond not just to straight-line deceleration but to the complex geometry of turns, uneven road surfaces, and heavy cargo that shifts as the vehicle negotiates a bend. The hydraulic network, therefore, is designed with careful redundancy and balance. It uses master cylinders that feed into a web of brake lines and valves, distributing consistent pressure to wheel brakes at each corner. In this configuration, even as the articulation introduces subtle changes in weight and load distribution, the system maintains predictable behavior, keeping damage to tires and suspension to a minimum while preserving steering control.

Advanced trucks also integrate safety features that refine how the service brakes interact with the vehicle’s broader safety repertoire. Anti-lock braking systems prevent wheel lockups during heavy braking, enabling the driver to steer while the brakes are applied. Electronic stability control takes that a step further by modulating braking force at individual wheels to maintain yaw and directional control on slippery or uneven surfaces. In combination, ABS and ESC help prevent skidding, reduce stopping distances on certain surfaces, and provide a margin of safety when the operator faces abrupt obstacles or sudden terrain changes. These systems don’t replace the driver’s judgment; they augment it, allowing more consistent deceleration and better control when road conditions deteriorate.

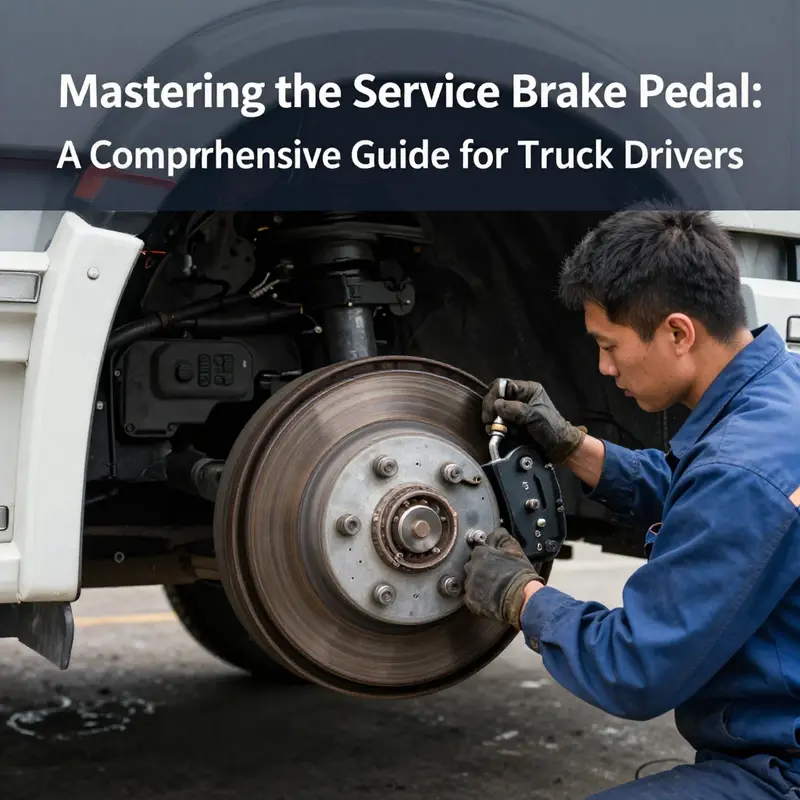

Maintenance and inspection are not afterthoughts in this framework. The reliability of the service brake greatly depends on routine checks of brake pads, rotors or drums, hydraulic fluid levels, and the integrity of lines and connections. Worn pads or overheated rotors reduce the system’s ability to convert kinetic energy into heat, increasing stopping distances and raising the risk of fade under prolonged use. Fluid quality matters, too. The hydraulic fluid must remain free of air and contaminants so that the pressure generated at the master cylinder translates cleanly into wheel brake force. Leaks in any portion of the circuit can erode braking effectiveness without obvious warning signs, which is why technicians perform comprehensive inspections that include listening for hissing from loose fittings, looking for seepage at joints, and measuring fluid levels against manufacturer specifications. In heavy trucks, where the braking system covers multiple axles, small compromises in one corner can propagate as uneven braking and reduced stability.

From the cab, the feedback through the service brake pedal is an important diagnostic signal. A firm, linear pedal feel generally indicates healthy hydraulic pressure and balanced brake force. A soft or spongy pedal, by contrast, often signals air entrainment or leaks in the circuit, requiring immediate attention. This is part of why drivers and maintenance personnel invest in systematic training around brake systems. Properly trained teams understand not only how to replace pads and check fluid but also how to interpret pedal feel, temperature signs on brake components after a road test, and the subtle cues that indicate an impending brake issue before it becomes a safety risk. Incorporating robust maintenance practices helps ensure that both the driver and the operator of the vehicle can rely on the braking system during the long hours of operation and in the most demanding scenarios. For those involved in preventive maintenance, structured programs—such as dedicated maintenance training resources—offer practical, scenario-based instruction that translates well to real-world work. See related training resources like fire-truck-maintenance-training-importance for a sense of the broader discipline and its relevance to high-stakes vehicle systems.

The community of professionals who work with heavy trucks knows that the service brake system is not a single component but a coordinated assembly that involves hydraulics, mechanical linkages, electronic safety aids, and a rigorous maintenance culture. The pedal is not just a click point; it is the driver’s invitation to engage a cascade of controlled reactions designed to stop a moving mass safely and predictably. In the context of articulated trucks carrying heavy cargo, the stakes are even higher. The jointed frame and multi-axle layout create unique thermal and mechanical challenges. Braking heat can accumulate quickly on long downhill grades, stressing pads, rotors, and the hydraulic lines that feed them. Consequently, engineers and mechanics emphasize heat management, ensuring components are rated for sustained deceleration and that the system’s thermal limits are respected through proper scheduling of use, periodic brake adjustments, and inspection after heavy-duty operation. This is why routine brake service—checking pad thickness, rotor wear, seal integrity, and fluid clarity—remains a cornerstone of safe operation in the fleet.

In practice, technicians approach brake service with a holistic mindset. They inspect not only the visible wear but also the health of the hydraulic circuit’s seals and fittings. They perform fluid tests to confirm the absence of water or contaminants, verify that there are no micro-leaks, and ensure the ABS modulator and wheel-speed sensors are functioning correctly. Each of these checks contributes to a reliable brake system that can respond to the driver’s requests with the same confidence from the first pull of the pedal as it does after hundreds of miles of service. The driver’s experience—whether easing to a stop on a grade, entering a tunnel, or stopping abruptly to avoid a hazard—depends on the builder’s attention to pedal feel, hydraulic integrity, and the interplay between mechanical wear and electronic safeguards.

Ultimately, the service brake pedal anchors a complex, dynamic system designed to keep heavy vehicles and their loads under deliberate control. It translates human intention into a precise hydraulic response, coordinates across multiple axles and configurations, and interacts with cutting-edge safety features that reduce risk in challenging environments. For operators and maintenance crews, understanding this interconnectedness fosters safer driving, easier maintenance decisions, and a longer service life for the truck and its braking components. The pedal, in short, is the human touchpoint with a highly engineered chain of events that makes stopping both predictable and reliable under a wide spectrum of operating conditions.

External resource for deeper technical context: https://www.cat.com/en_US/products/technical-publications/understanding-articulated-truck-braking-systems.html

The Quiet Anchor on the Road: Unpacking the Service Brake Pedal and Truck Safety

The service brake pedal may look like a simple foot-controlled switch, but in a truck it sits at the core of road safety. When a driver presses that pedal, the vehicle’s speed must bend to the driver’s will, and the mass and momentum of a heavy truck must be dissipated in a controlled, predictable way. In many trucks with manual transmission, the service brake pedal is the one pressed to slow or stop, often positioned as the leftmost pedal, though exact layouts can vary by model and configuration. The pedal is more than a mechanical interface; it is the decisive link between human judgment and machine physics. A timely, smooth response from the brakes can mean the difference between a routine stop and a crash, particularly on grade, in traffic, or in emergency response contexts where stopping power must be reliable and repeatable under pressure. Friction, hydraulics, and air pressure converge under the pedal to convert pedal travel into the gradual or assertive deceleration that keeps traffic around the vehicle orderly and predictable. When everything works as designed, drivers are empowered to manage speed with precision, to anticipate the stopping distances dictated by weight and weather, and to maintain that delicate balance between momentum and control. When any part of the braking system falters, the consequences can escalate quickly, because the service brake is tasked with handling the regular, day-to-day deceleration that keeps the highway system functioning safely for all users. This is not just about stopping at a light; it is about maintaining safe following distances, choosing appropriate speeds for entering curves, and retaining control when the road surface changes beneath a heavy truck’s tires. The service brake pedal is the instrument through which the driver translates perception and planning into safe vehicular motion, and its reliability underpins every decision made behind the wheel.

Key factors that affect safety hinge on the pedal’s performance at the moment of demand. First, malfunctions and failures loom as the most direct threat. Improper or inconsistent maintenance, worn brake pads or linings, and issues in the air-brake system—such as fluctuating air pressure or leaks—can dull the pedal’s bite or introduce delay. In air-brake configurations, the service brake pedal is intertwined with a system that relies on a steady supply of compressed air to apply the brakes. Any interruption in that supply, or a slow, uneven response from the control valve, can undermine stopping power precisely when it is most needed. Hydraulic leaks in conventional fleet brake lines can also reduce braking efficiency, leaving the driver with a pedal that feels soft, sinks under pressure, or requires extra travel before braking action begins. When these symptoms appear, drivers may compensate with heavier pedal effort or anticipatory downshifting, practices that, while common, do not replace properly functioning brakes and can mask underlying failures until a critical moment arrives.

Second, driver behavior matters immensely. Reaction time remains a constant human variable, and a delayed response can magnify the risk of a collision, especially in heavy traffic or on challenging topography. Beyond reaction time, how a driver uses the brakes in downhill situations, during sudden decelerations, or in response to a vehicle ahead alters the braking system’s lifespan and the vehicle’s stability. Over-reliance on the service brakes for speed control on long descents, for example, can lead to brake fade and reduced effectiveness. In contrast, a driver who understands braking dynamics can combine prudent speed management with judicious use of engine braking and downshifting, preserving brake life and maintaining vehicle control. These behaviors are teachable and measurable, and they are the primary targets of safety training programs that aim to reduce incidents caused by brake-related factors.

Mitigation begins with a commitment to system health and to the human factors that influence how the pedal is used in real-world conditions. Regular inspections of the braking system are essential. A preventive approach focuses on early detection: inspecting brake pads and linings for wear, checking the integrity of hoses and lines for hydraulic systems, and verifying that air-pressure levels in the reservoir and lines remain within specified ranges. The inspection routine should also assess the service brake valve and actuator performance to ensure that pedal travel translates accurately into braking force without delay. Fleets that integrate these checks into a broader maintenance cadence tend to catch issues before they become failures, reducing the likelihood of a pedal that feels soft or inconsistent under load.

Third, driver training and knowledge transfer are crucial. Training should illuminate the relationship between pedal input, vehicle weight, speed, and road conditions. Operators benefit from simulations or hands-on practice that demonstrate how braking behavior changes with load, grade, and surface friction. They should learn to gauge stopping distances under different scenarios, including those involving emergency braking, wet or icy pavements, and uneven road surfaces. A well-trained driver also understands the limitations of anti-lock braking systems, if present, and how ABS behavior should influence pedal application and steering input during a stop. Training that emphasizes perception, decision-making, and action helps bridge the gap between theoretical braking dynamics and effective, safe real-world driving.

A culture of safety support becomes the scaffolding for these technical and behavioral investments. Regular, structured maintenance training for staff and drivers reinforces the idea that safe braking is a collective responsibility. In environments that maintain a continuous improvement mindset—where technicians, operators, and supervisors share feedback and learn from near-misses—the service brake pedal becomes less about a single act and more about an integrated system performance. For fleets seeking practical, hands-on reinforcement of brake system care, resources like fire-truck maintenance training importance offer a concrete example of how ongoing, role-specific training can be organized and emphasized within a broader safety program. The linked reference provides a compact blueprint for keeping critical systems in repair-ready condition through targeted instruction and routine practice. fire-truck maintenance training importance.

Adherence to standards and regulatory guidance anchors all these efforts. Braking standards—and the procedures that ensure consistent interpretation and application of those standards—translate into clearer expectations for operators and better safety outcomes for the public. Regulations encourage regular brake system testing, inspection intervals, and documentation that trace any maintenance actions or observed anomalies. Beyond compliance, a safety-forward culture recognizes that the service brake pedal is a live interface with consequences in traffic, on grades, and in emergency response situations where a vehicle’s braking performance can determine how quickly and safely it can operate. The broader safety ecosystem—encompassing vehicle design, maintenance practices, driver selection, and ongoing education—works in concert to reduce the likelihood of a brake-related failure and to minimize its impact if one does occur.

In practice, the most resilient fleets implement a holistic approach: they treat the service brake pedal as a critical system component whose reliability depends on continuous attention to mechanical integrity, air and hydraulic health, and human factors. They invest in routine, data-informed inspections; they prioritize timely maintenance actions; they foster a culture where drivers are trained to interpret brake feel and pedal response accurately, and where managers understand the early warning signs of degradation before a fault escalates. These commitments do not only protect the vehicle’s occupants; they safeguard the wider traveling public by keeping stopping distances predictable, reducing the likelihood of runaway momentum on grades, and maintaining the control needed to navigate changing road conditions. They also reinforce a simple, enduring truth: a truck’s ability to slow and stop is the quiet anchor that steadies the journey, the point of contact where perception, physics, and practice meet.

For readers looking to explore the regulatory and practical underpinnings of truck brake safety in more depth, the U.S. National Highway Traffic Safety Administration provides official truck safety guidelines that frame the expectations and best practices for brake systems across commercial fleets. This external resource helps connect the day-to-day care of a service brake pedal with the larger safety architecture that governs heavy vehicles on public roads. https://www.nhtsa.gov/vehicle-safety/truck-and-bus-safety

The Leftmost Gatekeeper: Understanding the Service Brake Pedal Across Truck Models and Technologies

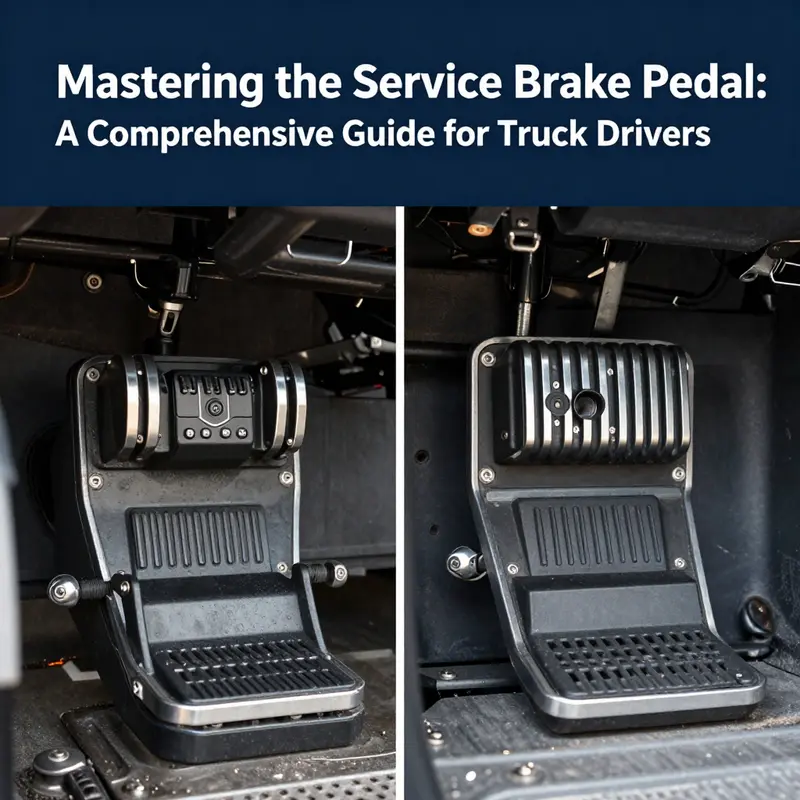

Among the controls that define a truck’s handing and safety, the service brake pedal is the most relied upon. It is the foot-operated interface that converts a driver’s push into the braking force that slows or stops the vehicle. In a standard truck with a manual transmission, the service brake pedal sits as the leftmost pedal, a position rooted in traditional layouts and ergonomic testing. Yet this placement is not universal. Some configurations rearrange pedal positions to accommodate automated systems or distinct cab layouts. Regardless of the exact row arrangement, the service brake remains the primary tool for deceleration in everyday driving, designed for both precision and endurance over long hours behind the wheel. Its predictable behavior is essential for smooth, controlled stops in urban deliveries, highway cruising, and the demanding tasks of heavy-duty operation.

The way a driver experiences that pedal depends almost entirely on the braking system technology beneath the hood. Trucks equipped with an air-over-hydraulic brake system (FK) typically exhibit lighter pedal effort than those using a standard hydraulic system with a vacuum booster. The lighter force reduces fatigue on long hauls and improves the ability to modulate pressure precisely during gradual deceleration. In contrast, full-air brake systems (FM)—which rely on compressed air to actuate brakes under heavy or demanding loads—often require a firmer push. The higher pedal force is not merely a matter of strength but a consequence of how air pressure, mechanical leverage, and brake actuation interact within the circuit. These differences matter because the pedal is more than a simple lever; it is a piece of feedback that tells a driver how the braking system is responding to speed, weight, and road conditions. A driver who understands these cues can anticipate stopping distances more accurately and adjust their input before the brake bite becomes sharp or sudden.

Pedal feel is not an abstract quality; it is a blend of travel, resistance, and tactile feedback. The journey from first contact to full engagement depends on travel distance—the amount of movement before the brakes begin to clamp—and on how resistance builds as the pedal travels toward the point of maximum braking. Researchers in braking ergonomics have refined methods to quantify pedal feel, focusing on initial travel, progressive resistance, and feedback quality. A systematic framework described by Lazaro Renato Oliveira in 2019 helps illuminate how design choices—such as pedal pad texture, spring stiffness, and mounting geometry—alter driver perception and control. When designers tune these elements to match the vehicle’s payload, steering effort, and road grade, the result is a more predictable, confidence-inspiring brake response that remains consistent across a fleet of trucks. This consistency is not only a matter of comfort; it translates into safer, more precise braking under varied conditions.

Beyond feel, the structural and ergonomic design of the pedal continues to evolve. Topology optimization and shape refinement aim to balance durability, weight, and ergonomic access. A contemporary line of research published through 2026 demonstrates how optimized pedal geometries can maintain structural integrity while reducing mass and improving ergonomic compatibility for the ankle and knee. The implications extend to maintenance and fleet management as well. A lighter, well-supported pedal can tolerate more cycles under heavy use and resist misalignment that might otherwise alter travel, touch, or bite. In practical terms, designers are investigating pad patterns, mounting points, and attachment methods that preserve a consistent and repeatable braking feel across a broad operating envelope—from rapid urban stops to long, steady descents on grade roads. This ongoing work helps fleets meet evolving safety standards while meeting drivers’ expectations for a responsive and fatigue-suppressing control.

From a fleet perspective, the service brake pedal’s performance is integrally linked to safety training and maintenance practices. The pedal’s behavior does not exist in isolation; it intertwines with anti-lock braking systems, electronic brake-force distribution, and, in air-based circuits, the cycling of the brake compressor. Regular inspection of pad wear, hose integrity, and booster calibration keeps pedal travel consistent and prevents unpleasant surprises under load. When pedal response deviates—whether a soft, sponge-like feel, a delayed bite, or a noticeably stiffer engagement—it can signal issues in the hydraulic circuit, air reservoir, or booster. For drivers, a stable, predictable pedal is a crucial cue. It supports smooth deceleration, reduces the likelihood of abrupt stops, and helps maintain steadier vehicle control when confronted with sudden traffic changes or slippery surfaces. The driver’s confidence in the pedal directly affects reaction timing and overall safety margins.

Although the service brake pedal’s core function remains the same, the driver’s experience can differ from model to model because of variations in brake architecture and system integration. A basic way to think about it is that air-over-hydraulic actuation tends to yield lighter, more featherweight pedal effort, whereas full-air configurations emphasize robust engagement under heavy load, often with a perceptible difference in bite and travel. Vehicle mass, weight distribution, and braking-torque characteristics further shape how much pedal movement is required before brakes bite decisively. These perceptual differences are not mere curiosities; they influence training programs that teach drivers to modulate input for predictable deceleration across payload ranges and terrain types. The aim is a consistent feel that reduces cognitive load during critical braking moments.

To anchor these design influences in practical terms, researchers have compiled model-to-model comparisons that reveal how pedal feel translates into braking performance. A detailed presentation from 2022 compares FK and FM configurations, offering insight into pedal effort, stopping distance under different loads, and subjective comfort indicators. While the full dataset lies beyond this chapter, the overarching message is clear: pedal design sits at the intersection of engineering capability and human perception. The focus extends beyond raw stopping power to how a driver senses and responds to the brake’s engagement, a nuance that governs reaction time and overall road safety. These findings underscore the importance of choosing brake architectures that align with a fleet’s typical operating profiles—urban deliveries, long-haul highway runs, or mixed-terrain assignments—and of pairing them with driver training that emphasizes consistent, proportional braking responses.

The broader movement toward improved pedal design is part of a larger effort to enhance efficiency and reliability in heavy-vehicle operations. The refinements being explored—geometric optimization, optimized pad layouts, and smarter attachment strategies—serve multiple goals. They reduce weight without compromising strength, improve durability under repeated use, and deliver a user experience that supports better driver posture and reduced fatigue. The end result is not only safer braking but also a driver who can keep focus on steering, traffic patterns, and path planning rather than fighting an inconsistent pedal. In fleets where drivers spend long hours behind the wheel, the value of a predictable pedal extends to overall job satisfaction and retention, as a comfortable, intuitive brake feel helps minimize the cognitive strain that can accompany demanding routes.

Given these considerations, the service brake pedal remains a central topic for training and maintenance programs in trucking operations. The seemingly simple act of pressing a pedal embodies a chain of interactions—hydraulic or pneumatic actuation, braking-force distribution, and electronic safety systems—that must operate in harmony to achieve smooth, controlled deceleration. When a fleet maintains a consistent pedal feel across the gamut of vehicle configurations and payloads, it supports safer driving, more predictable braking performance, and a steadier learning curve for new operators entering the cab. The leftmost pedal in a manual-gear truck is more than a position on the floorboard; it is a carefully engineered interface that communicates readiness, capacity, and control between human and machine, and it remains a focal point for both safety culture and ongoing engineering refinement.

For readers seeking a deeper dive into comparative braking architectures, a detailed, model-level study can offer valuable perspectives on FK, FM, and other hydraulic configurations. It is through such comparative work that fleets can align training, maintenance schedules, and procurement choices with actual braking-performance needs. When drivers and fleet managers understand the distinctions in pedal feel and effort, they can select configurations that support safer interactions on highways, grades, and urban corridors. The ultimate objective is to harmonize driver intention with vehicle capability, so every press of the brake contributes to smooth, timely deceleration rather than abrupt, jarring stops. For broader context on how design efficiency translates into practical outcomes, see the dedicated discussion on design efficiency in emergency services. [https://5startruckin.com/design-efficiency-in-emergency-services/]

External reference for model-level comparison and real-world data: https://www.scribd.com/document/537842976/MD-Trucks-Comparision-FK-FM-Presentation-2022

null

null

Final thoughts

The service brake pedal is more than just a mechanism; it is a fundamental aspect of truck safety and performance. Understanding its mechanics, ensuring its reliability, and performing regular maintenance are paramount for truck drivers and fleet managers alike. By gaining knowledge about the service brake pedal, stakeholders can enhance their operational efficiency, reduce risks, and maintain safer roads. Armed with this information, trucking professionals can make informed decisions that promote safety and efficiency in their driving practices.