Understanding trucklines is paramount for anyone in the trucking industry, whether you’re a long-haul truck driver or a fleet manager. These designated routes enhance efficiency in transportation services, ensuring seamless operations from maintenance to timely deliveries. As we delve into the workings of trucklines, we will explore their operational framework, economic implications, and essential safety regulations, particularly in aviation contexts. Each chapter will shed light on the significance of trucklines, illuminating their role in the logistics ecosystem and the broader transportation landscape.

Trucklines Revealed: The Hidden Arteries of Service in Modern Transportation

In discussions about how goods move from factory floors to storefronts, people often focus on routes, schedules, and fleets. Yet there is a quieter infrastructure that keeps those routes reliable and responsive: the truckline. The term may sit at the edge of everyday vocabulary, but in practice it describes a designated service pathway for trucks within larger operations. Think of it as the arterial road that underpins service activity rather than the main highway that carries volume. In many sectors, from manufacturing campuses to airports and industrial parks, this service line—this truckline—carries everything that keeps a system running smoothly: water for cooling, fuel for power, spare parts for maintenance, and supplies that push production, hospitality, and emergency response forward. The concept bridges pure freight movement with the more intimate chores of servicing a complex operation. When we ask what else people call a service line with trucks, truckline is the term that quietly fits the bill without losing its sense of specificity. It is a phrase that speaks to route planning, operational discipline, and the choreography required to deliver services along a dedicated path as reliably as goods move along a primary logistics spine.

To grasp why trucklines matter, it helps to begin with a clear sense of what a truckline is in practical terms. A truckline is not merely a random detour or a patch of road that trucks wander down in the course of a day. It is a defined network or sequence of intersections, ramps, and stops devised to move service-related freight efficiently. In many settings—airports, factories, refineries, large campuses—the truckline is mapped into the day’s dispatch plan. A water service truck may travel along a booked route to replenish lavatory or aircraft water systems. A galley service truck might move between kitchens and aircraft or dining facilities on a predictable path. In aviation parlance, these service vehicles operate on their own dedicated lines, separate from general freight lanes, to minimize interference with critical passenger or cargo movements. The phrase truckline appears in operational documentation and is often used informally by crews who rely on it to synchronize work across shifts and departments. This is where the term’s utility becomes evident: it captures a specialized form of service logistics that complements broader transportation networks rather than competing with them.

Historically, the emergence of trucklines mirrors the professionalization of logistics in the early 20th century. As road networks expanded and freight by road grew into a dominant mode for regional distribution, operations needed a discipline that could keep service activities predictable even as volumes rose. The concept of a line, in essence, provided a framework for consistency. The word itself—truckline—emerges from the simple, honest pairing of vehicle type and a defined route. It is a compound that travels well across industries, resonating with both planners and practitioners. In some dictionaries, the term is framed as a transportation system that conveys freight by truck, underscoring its enduring utility as a shorthand for a specific, repeatable service pathway. Even as technology reshapes how routes are optimized and tracked, the fundamental purpose of a truckline remains intact: to deliver service items where they are needed, on time, and with minimal friction.

The practical implications of trucklines extend beyond the movement of tangible goods. They influence the cadence of an operation, the reliability of supply, and the ability to respond to sudden needs without collapsing the schedule. When a maintenance crew needs a spare part at a moment’s notice, the efficiency of that fix depends on the existence of a well-planned truckline that can whisk the component along a precise route and arrange for a quick handoff at the right station. When a facilities team requires water for cooling or sanitation, a water service truck must traverse a sequence of stops that keeps systems online while avoiding bottlenecks in adjacent workflows. In airports and other high-stakes environments, the separation of service lines from main passenger or cargo lanes helps reduce congestion and enhances safety. The truckline therefore serves as a practical infrastructure for service continuity, the backbone of reliability that makes everything else in the logistics ecosystem possible.

From a regulatory and environmental standpoint, trucklines intersect with broader policy and compliance frameworks. They are not merely operational curiosities; they are subject to oversight, classification, and sometimes environmental reporting. Some regulatory literature describes a concept akin to trucklines as a named grouping within a vehicle fleet for emissions and compliance monitoring. The point is not to overstate a single term but to acknowledge that service-line operations have to align with environmental standards, fuel usage reporting, and fleet management practices. In this sense, a truckline embodies both the engineering of routes and the governance of how those routes are used. Its efficiency, therefore, has implications for fuel economy, emissions, and overall sustainability—issues that modern operations increasingly treat as core performance metrics rather than ancillary concerns.

Innovation is quietly reshaping how trucklines operate, just as it reshapes broader logistics. The rise of telematics, real-time tracking, and smart scheduling has turned an essentially static route into a dynamic sequence of potential adjustments. A service line can be interrupted by a temporary road closure, a shift in demand, or a weather event. With advanced routing logic and continuous communication among dispatch, drivers, and facility staff, a truckline can be reconfigured on the fly to preserve service levels. This adaptability matters because service lines often sit at the point where time-sensitive tasks intersect with safety-critical operations. A mismanaged fuel delivery or a delayed water service could ripple into production delays, customer dissatisfaction, or safety hazards. By contrast, a well-managed truckline that leverages live data can absorb disruptions with minimal impact, reallocate resources across lines, and maintain a steady rhythm of service delivery.

At the same time, sustainability remains a central driver of truckline evolution. Modern fleets seek to optimize not just routes but energy use. Fuel efficiency scales with smarter idling practices, reduced deadheading, and improved load planning. Alternative-energy trucks, hybrid powertrains, and battery-electric service vehicles are increasingly considered for service roles where emissions compliance and noise reduction matter—for example, in hospital campuses, airports, and urban industrial zones. The truckline becomes less a single path and more a portfolio of linked paths, each chosen for its balance of speed, reliability, and environmental footprint. In such a system, the line is still distinct, but the way workers interpret and follow that line reflects new levels of automation, data visibility, and cross-functional collaboration. The result is a service network that feels almost seamless, even as it stands on the edge of complex coordination.

A crucial toehold for broader understanding lies in how the concept translates across industries and geographies. In North America, trucklines are often discussed within the frame of domestic freight networks and campus logistics, where a defined route keeps maintenance and support operations on a predictable schedule. In other regions, the idea may appear in aviation or port operations, where dedicated service corridors serve aircraft, ships, or heavy machinery with precise timing and careful orchestration. The universality of the concept—moving service-related freight along a recognized path—helps explain why the term has persisted even as the tools and technologies around it have advanced. The core insight remains: service lines with trucks are about dependable, deliberate movement of what keeps systems alive, rather than merely about moving product from point A to point B.

To connect this idea with practical, real-world perspectives, consider how a service network is described in industry literature and practice. A broader look at how service networks operate can be found in analyses and case discussions presented by practitioners who emphasize reliability, uptime, and coordinated support. Such discussions remind readers that trucklines are not showroom features; they are operational requirements that directly influence uptime, safety, and the cost efficiency of the broader system. They are the invisible plumbing of the logistics world, buried in schedules, dispatch rules, and maintenance rosters, yet essential to the smooth functioning of every other activity that depends on timely, predictable service delivery. The analogy is apt: just as a road network underpins a city’s mobility, a truckline underpins the daily life of a complex operation where service tasks keep the whole enterprise moving.

The narrative of trucklines also intersects with the social and cultural dimensions of work in supply chains. Drivers, dispatchers, maintenance crews, and facility managers all contribute to the effectiveness of a service line. Their shared discipline—the habit of following a defined route, checking in at specified points, and coordinating handoffs with colleagues—creates a rhythm that translates into reliability for the end user. The quality of this rhythm depends as much on communication protocols and training as it does on a map or a GPS screen. In a world increasingly attentive to workforce development, specialized training for service-line operations can yield outsized returns in uptime and safety. When teams understand not only where to go but when to expect a handoff, the entire service line becomes a resilient component of the transportation ecosystem.

For readers seeking a concrete glimpse into industry practice, a broader exploration of service networks and their practical deployment can be found in industry resources that document non-mainline service approaches. A representative discussion of service networks—while not product-specific—offers context for how organizations structure, govern, and continuously improve these lines. The shared takeaway is that trucklines are not a relic of early logistics but a living part of modern operations, continually refined through data, collaboration, and strategic planning. In short, trucklines are where the theory of logistics meets the realities of daily work, and where innovation translates into steadier service and, ultimately, greater trust in the system.

As with any facet of modern transport and logistics, there is a balance to strike between standardization and flexibility. A well-designed truckline follows a standard, repeatable pattern that minimizes risk and enhances predictability. Yet it must also accommodate the unpredictable—surges in demand, equipment failures, or new maintenance requirements. The best operators view trucklines not as rigid scripts but as adaptive playbooks. They establish the routine, then empower teams to improvise within clear boundaries. This hybrid approach—stable lines with flexible execution—permits service teams to deliver what the broader operation relies on most: continuity and confidence. In a field where every minute matters and every component matters, the truckline is the quiet engine that translates planning into performance.

To emphasize the interconnectedness of ideas, consider a simple cross-reference: the truckline’s function in one domain often mirrors service-route logic in another. A water service truck routes to ensure uninterrupted facility hydration or aircraft water systems; a galley service truck ensures steady provisioning for dining operations. The same logic that guides these service itineraries also informs other specialized fleets across industries. The shared concept is a defined service route that optimizes for timing, safety, and minimal disruption to core operations. When readers encounter the phrase truckline, they should recall not just a word but a tactic—a way of thinking about how service work can be integrated into the daily cadence of a busy operation.

For those who want to explore further, one illustrative path is to examine how service networks are described in industry narratives and practitioner research. A deeper dive into the broader practice of service logistics provides useful context for those who are trying to translate the truckline concept into their own organizations. This broader lens helps readers see that a truckline is not an isolated artifact but a fundamental component of integrated operations that connects maintenance, provisioning, and facility continuity with the ultimate goal of reliable service delivery. In that sense, trucklines are both a descriptive label and a working blueprint for how to keep essential services moving on a busy floor, campus, or airport apron.

Finally, while the term truckline has practical resonance, it also invites reflection on language itself. Naming matters because it frames how teams think about their work. Calling a service route a truckline elevates it from a mundane sequence of deliveries to a deliberate, repeatable process that warrants attention, measurement, and continuous improvement. It invites managers to ask better questions: How well does our truckline align with the rest of the service ecosystem? Are dispatch protocols synchronized across shifts? Do we have real-time visibility into each leg of the line? How can we reduce wait times without compromising safety? These inquiries keep the concept alive and actionable, ensuring that the truckline remains a source of reliability rather than a passive background feature of an otherwise efficient system.

The next chapter will build on this foundation by turning to analysis of how service lines with trucks integrate with broader network design, including considerations around capacity planning, cross-docking, and peak-demand strategies. It will also look at how emerging technologies—from predictive maintenance to advanced routing algorithms—reshape the performance benchmarks for trucklines. For readers curious about practical applications and case insights, a broader look at service networks and their deployment can be found here: Discovering-the-unparalleled-services-of-5-star-truck-inc. This cross-reference helps connect the theoretical framing of trucklines with real-world practice, reminding us that the language we use—truckline, service line, or any other label—serves to illuminate where care, precision, and coordination converge in the daily work of keeping transportation services moving.

In sum, trucklines deserve a central place in any discussion of how service movements are organized within transportation systems. They are the dedicated routes that ensure maintenance crews, fuel deliveries, and provisioning teams reach the right place at the right time, with minimal disturbance to core operations. They embody the principle that reliable service is not merely a byproduct of good planning but a deliberate outcome of disciplined routing, thoughtful scheduling, and continuous improvement. As logistics networks continue to grow in complexity and scope, the truckline stands as a practical testament to how precise, well-designed service pathways enable the broader system to perform—and to do so with greater efficiency, safety, and resilience. Looking ahead, the emphasis on smarter trucklines will intensify as fleets become more connected, data-informed, and responsive to the needs of an increasingly dynamic transportation landscape, reinforcing their role as the quiet engine of modern service delivery.

External reference: The usage of service lines and vehicle grouping for regulatory and communications contexts is discussed in aviation regulatory materials, including the China Civil Aviation Administration’s Air Traffic Radio Communications Phraseology, which notes examples like water service trucks and galley service trucks operating on dedicated service lines. See the external source for context on how terminology and procedure align in aviation environments: https://www.caac.gov.cn/WMJS/XXGK/XTZT/201905/t20190531_197468.html

Trucklines Unveiled: Naming the Arteries of Modern Service Fleet Operations

In fleet operations, words matter as much as wheels and fuel. The term truckline designates the dedicated corridor along which service vehicles travel to perform routine tasks, coordinate handoffs, and maintain safety. It is more than jargon: it is a label that channels expectations about routing discipline, timing, and accountability.

In aviation and industrial settings, a truckline maps to a functional space rather than a generic road. Water service trucks, galley service trucks, and maintenance crews are described as operating on specific service lines—commonly referred to as trucklines by dispatchers and crews. Naming the line embeds a shared vocabulary that aligns teams and customers around predictable cadences and service windows.

The practical value goes beyond labels. A truckline becomes a planning and execution framework that coordinates several moving parts: where trucks travel, where they halt for servicing, and how handoffs occur between teams. The result is reduced ambiguity during peak windows and unexpected disruptions. The vocabulary also supports training so newcomers learn which corridor handles refueling, which serves catering, and how to coordinate with luggage or cargo handling in adjacent lanes.

Real-time tracking brings the line to life. GPS and telemetry provide visibility into each truck’s location, status, and proximity to the next point. Dispatchers can adjust schedules, reallocate capacity, and inform customers with timelier updates. Data from the line informs performance metrics such as on-time delivery, fuel efficiency, and maintenance costs, while governance around data, security, and privacy keeps this insight responsible.

Electrification and new business models further reshape trucklines. Electric fleets change charging logistics, peak-demand planning, and multi-year energy cost modeling. The concept of Truck as a Service adds an operating model where ownership and day-to-day routing and maintenance may be provided by a partner, accelerating adoption of advanced technologies and reducing risk for fleets.

Finally, governance, contracts, and design thinking reinforce the line’s resilience. Long-term agreements clarify service levels and data-sharing norms, while dynamic planning tools help reallocate capacity in response to demand shifts or disruptions. Across industries, naming and managing trucklines supports safety, reliability, and continuous improvement, turning a route into a living, auditable process.

Naming the Route: The Economic and Operational Impact of Trucklines on Modern Logistics

The power of a name often shapes decisions, contracts, and daily work. In logistics and industrial services, the term truckline designates a designated line, route, or sequence along which trucks perform essential service tasks—refueling, maintenance, or the delivery of supplies—often within airports, seaports, manufacturing campuses, or logistics hubs. This naming is more than semantics; it frames expectations about reliability, scheduling, and the ability to coordinate activities into a single, predictable flow.

In many operational manuals and service procedures, the phrase truckline appears as a shorthand for a specialized service corridor involving one or more trucks executing discrete, time-bound tasks. The concept carries an implicit contract: a line with trucks is not just a path on a map but a system designed for efficiency, readiness, and synchronized handoffs. To call it simply a route would miss the layered purpose—an engineered sequence where timing, location, and task type are harmonized to reduce idle time and waste. In that sense, trucklines act as architectural elements of the broader logistics network, shaping both cost structures and service levels.

From a naming perspective, several aliases coexist with truckline, each carrying its own emphasis. A service line with trucks might also be described as a truck service route, a service corridor for fleet operations, or a designated service lane in industrial facilities. The terminology chosen can influence planning conversations. When planners speak of a truckline, they invite a discussion about scheduled sequence and fixed touchpoints that enable tight coordination with other nodes in the network—receiving bays, maintenance docks, water or galley stations at an aircraft stand, or bulk supply points at a campus. This is not just about moving goods; it is about synchronizing activities so that a single truck can complete multiple micro-tasks within a carefully orchestrated window. The language matters because it signals whether the operation is a loosely arranged set of ad hoc trips or a structured, repeatable process that can be scaled, measured, and improved through data.

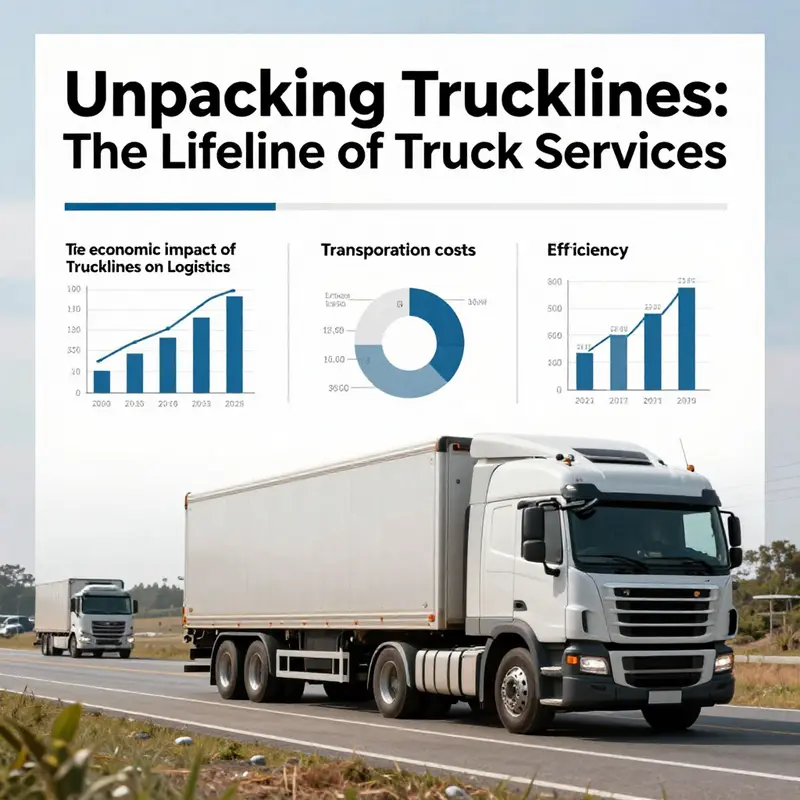

Economics follows the language. When a business adopts the truckline framework, the most immediate effect is a shift in economies of scale. Consolidating shipments and scheduling a sequence of tasks along a predefined line allows for higher truck utilization rates. Instead of isolated trips to multiple destinations, a truckline approach makes it possible to bundle complementary activities, reducing the total number of trips required to fulfill a set of service obligations. Lower per-unit costs begin to accrue from several channels at once: fewer miles traveled per delivered unit, better load factor, and more predictable fuel and depreciation calculations because routes become standardized rather than bespoke. In practice, these efficiencies compound. A fleet can run more consistently, maintenance teams can align preventive work with predictable downtimes, and fuel procurement can be synchronized with a known schedule rather than secured on an as-needed basis. The logistics provider, in turn, can extend its capacity without a proportional rise in capital expenditure, because the line’s predictability improves the ability to plan asset utilization across the network.

Alongside cost advantages, trucklines improve a business’s ability to forecast and manage risk. The reliability of a scheduled service line reduces lead-time variability, a factor that often erodes margins when demand spikes or product mix shifts rapidly. With a well-managed truckline, inventory holding costs shrink, and the need for safety stock diminishes. The consequence is a leaner balance sheet and more agile cash flow. When lead times become steadier, procurement and production planning can rely on shorter, more accurate replenishment intervals. In turn, supplier relationships—whether with internal departments in a multinational campus or with external clients at a logistics hub—gain clarity and predictability. Such clarity has downstream effects on service quality, customer satisfaction, and the ability to compete on reliability rather than price alone.

The reliability story is inseparable from the route optimization story. Trucklines enable real-time data to influence routing decisions, a capability that becomes particularly valuable when schedules must absorb variability in demand, weather, or congestion. The integration of tracking and analytics turns a line into a digital spine for the operation. Rather than a fixed path with a fixed outcome, the truckline becomes an adaptive system that re-sequences tasks, reallocates loads, and re-times arrivals while preserving the integrity of the overall service schedule. In practical terms, dynamic routing within a truckline can shorten idle times, reduce unnecessary waiting at service points, and minimize the number of trips needed for a given service objective. These improvements translate directly into lower fuel use, less wear on vehicles, and a more stable labor plan. The combination of standardization and adaptability is particularly potent in environments where services must be coordinated with other high-stakes activities, such as passenger transportation schedules at an airport or high-priority maintenance windows at a manufacturing campus.

The environmental dividend of trucklines also deserves attention. The same logic that drives cost savings—fewer trips, better load factors, and more precise scheduling—also reduces waste in the form of idle engine running, duplicated routes, and erratic trip lengths. A study documented in the International Journal of Production Economics underscores that reducing transportation lead-time variability yields both economic and environmental benefits. By minimizing erratic trips and idle time, trucklines contribute to lower emissions per unit of service completed and to a more sustainable logistics footprint. This dual benefit—economic efficiency and environmental stewardship—helps explain why many organizations, across different sectors, invest in robust truckline infrastructure as part of a broader push toward sustainable operations. The link between predictable service lines and lower environmental impact is not purely theoretical; it translates into measurable reductions in fuel consumption, greenhouse gas emissions, and fuel-related maintenance costs. As environmental regulations tighten and stakeholder expectations rise, the strategic value of a well-designed truckline grows even more pronounced.

Of course, investing in a truckline is not a universal solution. There are costs to consider, including the initial design of the service route, the need for dedicated docking or staging areas, and the governance structures required to maintain schedules and performance metrics. A truckline demands discipline: clear responsibility assignments, robust standard operating procedures, and ongoing performance monitoring. The capital required to establish integrated service points—such as fueling bays, docking docks, or maintenance cells aligned with the line—must be weighed against the long-run savings from improved utilization and reduced variability. In some contexts, the line can be partially deployed, functioning as a hybrid between ad hoc trucking and a fully structured service corridor. The decision hinges on the scale of operations, the frequency of service tasks, and the reliability of ancillary processes that must interlock with the line. When done thoughtfully, a truckline becomes less a buffeted exception in logistics and more a backbone around which complex tasks cohere.

Terminology, again, is not merely academic. The choice of terms influences contract design and performance metrics. If a client or partner expects a routine stream of service within a truckline framework, service-level agreements can be crafted to emphasize punctuality, loading accuracy, and minimized dwell times. When the term truckline is used in procurement or operations planning, it signals a structured approach with defined touchpoints, which in turn guides measurement and accountability. Conversely, treating the same operational reality as a generic route can obscure the systematic changes needed to achieve high performance. In short, naming the route matters because it frames what is possible and how success is defined. The better the words capture the routine, the more effectively teams can optimize, monitor, and evolve the practice over time.

As organizations contemplate the future of service delivery, the truckline concept invites a broader reflection on how to design for resilience. The most resilient logistics networks are those that can absorb disruption without sacrificing service levels. A truckline, properly conceived, can serve as a modular element of resilience—an adjustable, repeatable pattern that can be scaled, re-sequenced, or repurposed as needs shift. In this sense, the truckline is not just an operational shortcut; it is a deliberate architectural choice about how to structure service delivery to align with demand patterns, supply contingencies, and the broad objective of reliable, timely support for customers and operations alike. When viewed through this lens, the chapter’s core message crystallizes: the name we use for a service line with trucks is more than a label. It is a blueprint for efficiency, risk management, and sustainable growth.

For readers seeking a practical anchor in this discussion, the overarching takeaway is that embracing a truckline mindset can unlock tangible economic and environmental benefits by elevating predictability, capacity utilization, and speed to serve. The precise terminology matters because it signals a commitment to a repeatable, measurable, and optimizable process. In environments where service lines with trucks intersect with other critical flows—whether aircraft support, campus operations, or interfacility logistics—the disciplined application of truckline principles can transform marginal gains into meaningful performance improvements. As with any system designed to reduce waste and amplify value, success rests on thoughtful design, careful measurement, and disciplined execution across planning, operations, and compliance.

Rethinking the Truckline: Naming, Safety, and Regulation of Aircraft Service Routes

In aviation and allied industrial settings, the language we use to describe the pathways for service vehicles matters as much as the machines themselves. A term that often crops up in manuals and on the tarmac is truckline—a designation for the dedicated line or route that trucks follow to deliver services to aircraft and related facilities. This simple phrase belies a broader ecosystem of logistics, safety culture, and regulatory discipline. In practice, a truckline may carry a water service truck to replenish onboard systems, a galley service truck to restock catering units, or a fueling vehicle to transfer aviation fuels along carefully engineered corridors. In some contexts, technicians and operators informally extend the concept to refer to any service route where trucks routinely operate in proximity to aircraft or critical infrastructure. The language is functional, but it also carries tacit expectations: coordination, predictability, and strict adherence to procedures that minimize risk in environments where mistakes can escalate quickly. Across different airports, airfields, and logistics hubs, the phrase truckline serves as shorthand for a composite of routes, procedures, and safeguards designed to keep services moving smoothly while preserving safety and efficiency. The nuance of naming here is not cosmetic. It shapes how crews communicate, how maintenance teams prepare, and how regulators evaluate risk and compliance. When the term appears in international and national guidance, it acts as a signal that a set of standardized practices governs movement along a defined path, with clear responsibilities, constraints, and contingencies anchored to the aircraft and its immediate support network. In this sense, trucklines do more than organize traffic; they institutionalize a particular mode of operation that foregrounds safety, discipline, and situational awareness. A useful reminder of this comes from operational phrases used in civil aviation communications, where specific service vehicles—such as water service trucks or galley service trucks—execute tasks along defined service lines. In these contexts, the existence of a dedicated truckline is not merely about logistics; it is about creating a controlled environment in which potentially hazardous activities can be conducted with precision and accountability. The term is widely recognized in technical and operational documentation, and it resonates with anyone who has seen how routine tasks like refueling, maintenance, or provisioning are orchestrated around the aircraft, the crew, and the surrounding workforce. Yet naming is only one facet of the larger conversation about how best to manage service lines in aviation. The substantive concerns revolve around safety design, regulatory compliance, vehicle performance, and the competencies of people who operate and oversee these systems. In many airports, especially those with military or remote-operational characteristics, the dynamic environment imposes additional demands. Procedures must accommodate variability in weather, visibility, and aircraft type, while still ensuring that the truckline remains a predictable, auditable channel for service delivery. This is where the chapter’s core themes—safety, training, and regulation—coalesce. The safety architecture surrounding a truckline is multi-layered. First, the design of the service vehicles themselves must anticipate the highest risks that could arise during routine operations. Anti-ignition design features, robust static management, and careful separation of fuel handling from other functions are standard expectations. Vehicles may require explosion-protection design elements to withstand potential ignition sources in high-risk environments. Second, a robust grounding strategy minimizes the accumulation of static electricity, which can be a critical ignition pathway in fueling operations. Grounding points, bonding procedures, and meticulous fuel transfer practices help ensure that every connection and transfer occurs with minimized risk. Third, automated safeguards, such as rapid shut-off valves and integrated leak detection, provide immediate redress in case of abnormal pressure, temperature, or flow conditions. The deployment of real-time monitoring systems completes the safety triad by continuously surveilling connections, temperatures, and leaks, enabling operators to react swiftly to anomalies. When these layers work in concert, a truckline becomes less a passive roadway and more a managed process that integrates hardware, software, and human judgment. The human element cannot be overstated. Training programs for every crew member—mechanics, operators, supervisors, and fueling attendants—build a shared understanding of emergency response, spill prevention, and environmental protection. The emphasis on training aligns with international expectations and national regulations alike. Operators must be familiar with emergency shutdown procedures, fire response protocols, and the steps required to isolate a fault before it escalates. This is not a one-off requirement but a continuous discipline. In service environments where regulatory expectations are mapped across different jurisdictions, the onus falls on organizations to maintain competence and preparedness. Agencies such as the International Civil Aviation Organization (ICAO) articulate comprehensive guidance that covers the handling of aviation fuels from transport to final fueling. The aviation fueling domain requires adherence to precise procedures and qualification standards for personnel, facilities, and vehicles. The chapter’s focus—safety and regulatory considerations for trucklines in aviation—therefore intersects with a suite of instruments designed to minimize risk in a high-stakes setting. Regulators at national and regional levels specify inspections, certifications, and ongoing surveillance of service vehicles and their operating environments. In aviation, where operations may occur in dynamic places such as military bases, remote airfields, or emergency deployment sites, regulatory frameworks sometimes adapt to circumstance without compromising core safety principles. The result is a robust but adaptable compliance culture. A critical component of this is the specification of vehicle performance features that address both routine needs and extraordinary scenarios. Fuel trucks, for example, often incorporate onboard filtration systems to preserve fuel purity and avert contaminants from entering aircraft engines. They also emphasize maneuverability and compact dimensions, enabling access to non-traditional or constrained operating sites. The resilience of the truckline depends on these capabilities, so the vehicle design must balance throughput with precision and control. At the same time, regulatory expectations demand regular checks, maintenance, and certification. Audits may examine how well valves and shut-off mechanisms function, whether grounding points are intact, and whether monitoring systems provide verifiable data traces. The criteria vary by region, but the underlying logic is consistent: vehicles must be in a state that supports safe operation under a range of conditions, and there must be documentation that proves ongoing compliance. In many Commonwealth and Commonwealth-like environments, operators have long adhered to established local conventions for fueling and service lines, including annual or biannual inspections and routine system tests. This is not merely procedural ritual; it is a practical acknowledgment that service lines operate at the intersection of safety-critical systems and time-sensitive logistics. The interplay between naming conventions and procedural rigor is subtle but real. When teams refer to a truckline as a defined corridor or service route, they implicitly signal a structured approach to risk management. The same language that emphasizes the route also carries the memory of the safety checks, training records, and regulatory touchpoints that anchor responsible operation. The broader narrative here is one of coherence: how do we ensure that a service line with trucks remains a controlled, auditable, and reliable element of aviation infrastructure? The answer lies in harmonizing terminology with practice. Clear naming helps align expectations across teams—from fueling crews and ground handling to air traffic services and regulatory inspectors. It also fosters continuity when operations shift from one context to another, such as from airport-based fueling to remote deployments at austere sites. In the aviation fueling domain, where a truckline often functions as a critical artery for life-sustaining services, the emphasis on standardized procedures cannot be overstated. The International Civil Aviation Organization’s Manual on the Handling of Aviation Fuels serves as a cornerstone for practitioners seeking authoritative guidance. It codifies the steps, equipment requirements, and personnel qualifications that govern the journey from fuel transport to aircraft fueling, offering a framework that can be adapted to local regulatory landscapes while preserving universal safety principles. For readers seeking practical, in-depth guidance, the manual provides a comprehensive reference that complements national regulations and operator-specific policies. The careful integration of global standards with local practices ensures that trucklines do not become points of fragility, but rather channels of dependable service that support safe flight operations. In connecting these threads—the naming conventions, safety architecture, regulatory expectations, and vehicle performance—the chapter reinforces a crucial point: the terminology surrounding service lines with trucks is more than linguistic convenience. It is a reflection of a safety culture that treats every maneuver along the truckline as a potential risk scenario to be anticipated and mitigated. The most effective operational models treat trucklines as living systems. They are designed with robust hardware features, supported by reliable software monitoring, and sustained by people who are trained to respond to the unexpected at a moment’s notice. And because aviation is inherently interconnected, the governance of trucklines transcends the confines of a single airport or country. It is a shared discipline that links the terminology used on the ramp with the standards used in international guidance and the day-to-day realities of operations on the ground. To illustrate how organizations translate these principles into practice, consider the procurement and deployment of service vehicles used in critical operations. Purchasing decisions are guided by stringent safety criteria, maintenance planning, and crew training requirements. In this context, the phrase fire-apparatus-procurement can serve as a practical reference point for teams assembling fleets that will operate in aviation settings, where the stakes are high and the margins for error are slim. The decision process emphasizes not only the capabilities of the vehicle but also the alignment of its safety features with the truckline’s risk profile. This alignment ensures that every vehicle entering service, every connection made during fueling, and every interaction with aircraft occurs within a framework designed to protect people, property, and the environment. For readers who want to explore procurement considerations more deeply, a concise, real-world reference point is available through industry practice discussions that connect safety, reliability, and cost management in a unified approach. As the field evolves—with evolving fuels, new containment and spill-response technologies, and more stringent regulatory expectations—the concept of the truckline will continue to adapt. Yet its core purpose remains constant: to provide a safe, predictable, and well-governed pathway for service trucks to deliver essential goods and services to aircraft and aviation facilities. In this light, the language of trucklines becomes a compass for coherence across operations, risk management, and compliance. It is a reminder that naming is not mere nomenclature but a starting point for a disciplined, safety-first approach to aviation support services. External guidance remains a critical companion in this journey. For authoritative, comprehensive coverage that informs policy, engineering design, and operational practice, consult the ICAO Manual on the Handling of Aviation Fuels. This resource anchors safety objectives in internationally recognized standards and supports practitioners as they navigate the complex realities of fueling, maintenance, and provisioning along dedicated service lines. ICAO Manual on the Handling of Aviation Fuels

Internal link reference: For procurement-centered perspectives that tie into the broader safety and reliability discourse around service vehicles, see the discussion on fire-apparatus-procurement. fire-apparatus-procurement

Final thoughts

Trucklines are not just logistical pathways; they are integral to the efficiency and safety of transportation services across various sectors. By understanding their operational framework, economic significance, and regulatory considerations, industry professionals can leverage trucklines to enhance their service offerings. Embracing these insights allows for better planning, compliance, and ultimately, competitive advantage in the trucking landscape.