The U.S. Forest Service operates under some of the most challenging conditions imaginable, emphasizing the need for specialized vehicles that can thrive in rugged terrains and unpredictable weather. For long-haul truck drivers, trucking company owners, fleet managers, and aspiring truck drivers, understanding what kinds of trucks are utilized by the Forest Service can deepen insights into the unique demands of forestry and firefighting operations. This article delves into the fascinating world of Forest Service vehicles, covering the robust 4×4 Utility Trucks, the specialized Firefighting Trucks, Utility and Work Trucks, and the durability and off-road capabilities that define these vehicles. We will also examine the regional variations that cater to specific operational needs, providing a comprehensive overview that enhances your understanding of the critical role these trucks play.

Rugged Rails of Readiness: Four-Wheel-Drive Utility Trucks in Forest Service Operations

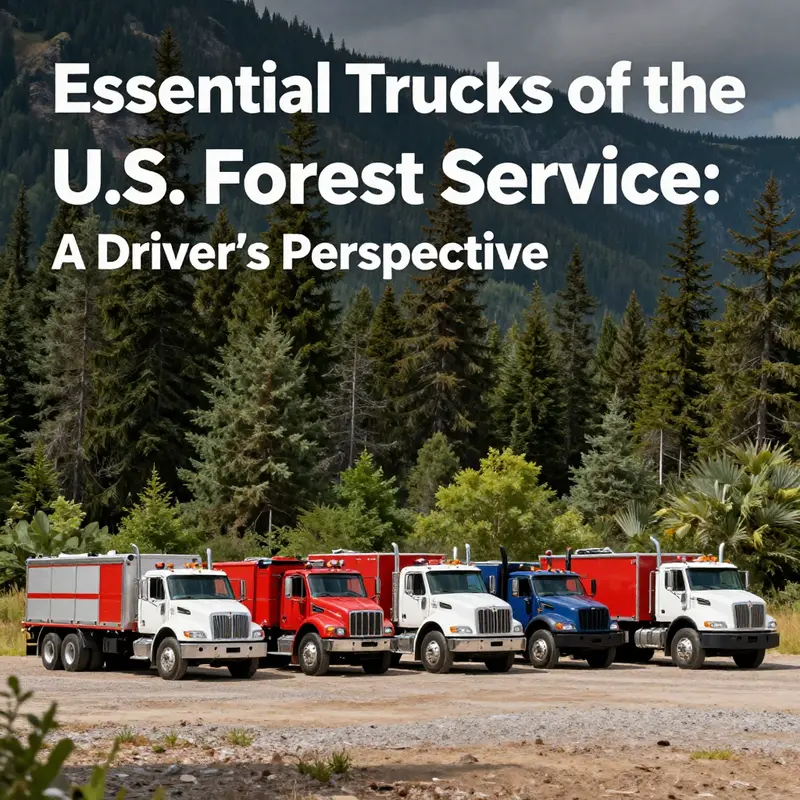

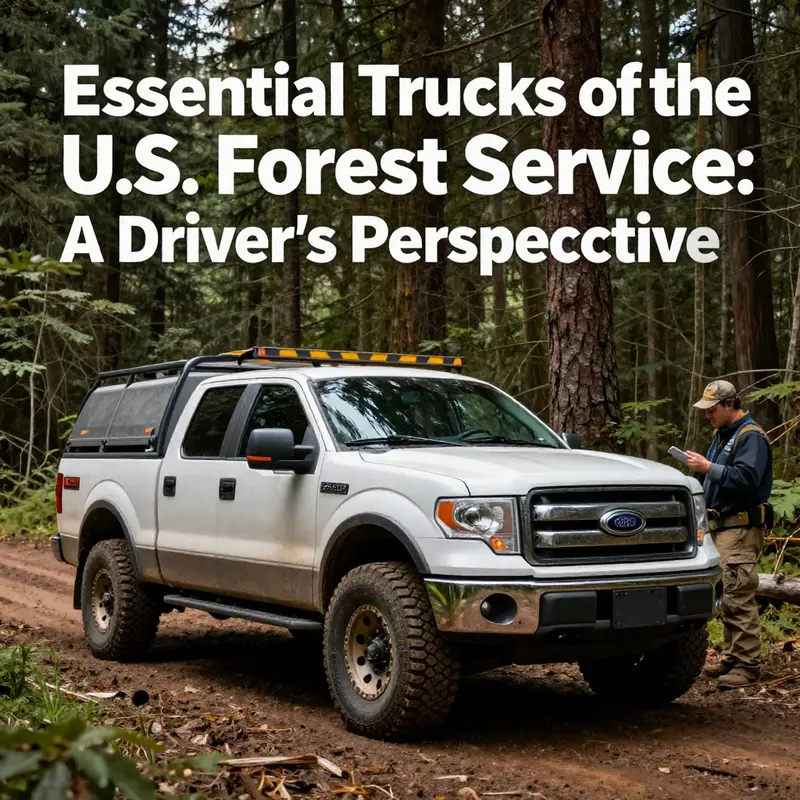

Across the diverse landscapes of national forests, the Forest Service relies on a fleet of four-wheel-drive utility trucks to move people, gear, and supplies through rough terrain. These vehicles are not flashy; they are dependable workhorses designed for backcountry patrols, maintenance tasks, and rapid dispatch of crews to wildfire fronts. Their rugged drivetrains, durable suspensions, and modular bed configurations enable field adaptation: from water tanks and chainsaws to survey gear and rescue equipment.

In practice, four-wheel-drive utility trucks balance compact maneuverability with enough muscle to haul gear, personnel, and sometimes water or fuel to the work site. A typical fleet comprises light- to mid-weight pickups that can serve as a one-truck solution for small districts or a versatile asset within larger operations. Optional winches, skid plates, reinforced frames, and modular cargo systems let crews tailor the bed or cab to the mission.

Across ranger districts, configurations vary: lighter 4×4 pickups for tight timber stands and remote camps, or crew-cab variants with greater cargo space for equipment and teams along service roads and wildfire perimeters. The shift toward modular beds reflects evolving demands and remote operations. A truck may begin life as a patrol vehicle but can be outfitted to carry water, pumps, or firefighting gear for a high-fire workload.

In the field, reliability is king. A four-wheel-drive utility truck must perform in rain, mud, snow, and dust, with minimal downtime and straightforward maintenance. The emphasis is on durability, off-road capability, and simple maintenance cycles, ensuring a vehicle is ready when needed and stays operational to complete essential tasks.

Maintenance and readiness are as critical as raw power. Routine inspection of brakes, tires, fluids, and wiring, performed by drivers and mechanics, ensures uptime in remote locations where every minute counts. The aim is dependable performance, with a focus on easy serviceability and field-tested reliability.

Viewed in sum, these trucks balance size, capability, and agility. Larger vehicles offer more cargo capacity but can slow operations in tight terrain, while smaller trucks offer speed and accessibility. A managed mix of configurations allows districts to select the right tool for the terrain and the mission, maintaining resilient operations that keep forests healthy and safe.

Rugged Response: Specialized Firefighting Trucks Keeping Forests Safe

When the forest is at risk, the field response hinges not only on the crews who fight flames but on the machines that carry them to the heart of a remote blaze. The U.S. Forest Service maintains a diverse fleet of trucks designed to withstand unpaved forest roads, steep grades, loose gravel, and long miles from the nearest water source. Among these, specialized firefighting trucks form a core line of defense for wildland fires, especially where traditional apparatus would struggle to reach or operate effectively. The aim is not only to move quickly but to deliver water, deploy suppression tools, and protect structures with mobility that stays ahead of the fire’s erratic pace. In practice, these vehicles embody a philosophy of rugged reliability and tactical flexibility, engineered to perform under the most demanding conditions while remaining a dependable backbone of incident command teams that must coordinate on the move across rough terrain. In the long arc of fire season, such trucks are the difference between quickly establishing an effective initial attack and watching a small flame evolve into a landscape-altering burn.

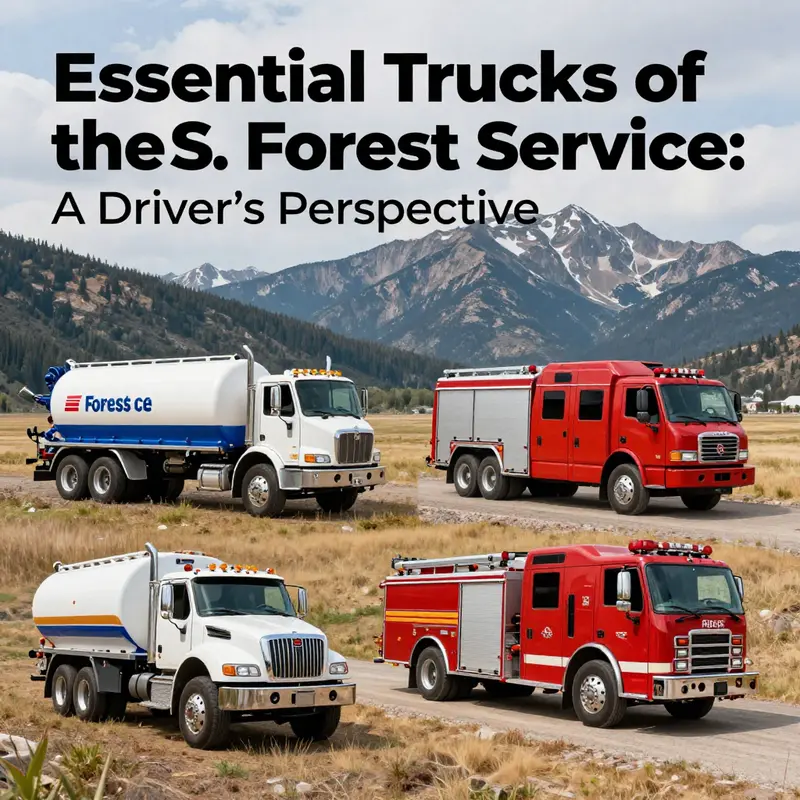

A central pillar of this specialized fleet is the Type 3 wildland fire engine, a workhorse designed for rescue, protection, and direct attack when hydrants are scarce or nonexistent. These engines ride on sturdy chassis and employ four-wheel drive to conquer slopes and uneven surfaces where other apparatus would stall. They carry a substantial water supply and a high-capacity pump capable of delivering a steady stream of water to the flame front. In practical terms, this means hot, immediate action against a fire front with the option to shuttle water from remote sources. The practical advantage is clear: on rugged backcountry roads, where a hydrant network simply does not exist, a Type 3 engine can position close to the line, begin suppression quickly, and pull back to safer ground to refill. The design emphasizes mobility and durability. A compact, agile footprint allows crews to pivot around rocks, ruts, and undergrowth that would impede larger trunks of apparatus. The pump’s output, typically measured in hundreds of gallons per minute, supports both direct attack at the flaming edge and defense lines around vulnerable structures or critical habitat. In service, these machines enable a rapid, disciplined response that minimizes the need for long water shuttle operations when immediate fire suppression is the priority.

Beyond the Type 3 engine, the Forest Service maintains trucks built for scenarios that push suppression beyond the ordinary. In very high-intensity fires or zones with hazardous materials, the department deploys heavier, more capable firefighting trucks. These are designed to endure extreme heat, resist damage in industrial-wildland interface settings, and offer robust protection to the crew while delivering sustained suppression capabilities. They may carry larger tanks and more powerful pump systems, allowing for extended operations when water sources are distant or inaccessible. Such vehicles complement the lighter, more agile Type 3 engines by extending the reach of suppression efforts and providing a platform for advanced operations, including defense of critical infrastructure and coordination with incident management teams that are managing fires from a distance or across a network of routes where every mile of travel matters. The emphasis remains squarely on reliability and survivability: a vehicle that can traverse rough approaches, park on uneven ground near the most threatened zones, and deliver steady, predictable performance under heat and pressure. In practice, this means a chassis and drivetrain engineered for endurance, a high ground clearance to clear debris and rough roads, and a pump system that can maintain a steady head even as the fire’s intensity shifts and the terrain becomes a test of traction and stability.

In addition to the core engines and heavy responders, the forest firefighting fleet includes other specialized support vehicles that ensure water, tools, and personnel can reach where they are needed most. Water tenders, for instance, play a crucial role in supplying large volumes of water to remote sites. They bridge the gap created by the scarcity of hydrants in wilderness and rural wildland-urban interface zones, making it possible to sustain suppression efforts without returning to distant water sources. The Forest Service also relies on utility and work trucks that carry equipment—chainsaws, grapples, hose packs, hand tools, and protective gear—allowing crews to perform line construction, wind-fall clearing, and hazard mitigation on the ground. While these vehicles may not stand at the fire line with the same fire suppression power as the engines, their contributions are essential. They enable crews to access the right locations, prepare containment lines, and maintain the continuity of operations once suppression begins. The synergy between these varied vehicle types, the small, highly maneuverable 4×4 utility trucks; the Type 3 engines; the heavier, more rugged fire apparatus; and the support trucks, creates a resilient, adaptable system much larger than the sum of its parts. Each vehicle type fulfills a distinct function, but they share a core creed: to reach people and places where fires threaten communities, ecosystems, and critical infrastructure.

Design and capability choices for specialized firefighting trucks reflect the realities of forest terrain. The emphasis is not on sheer speed alone but on the ability to deploy quickly and sustain operations once on site. Four-wheel drive, high ground clearance, robust suspension systems, and durable, heat-resistant components are nonnegotiables. The equipment carried on board—pumpers, sufficient water reserves, and water delivery capabilities—must align with the geography and water economics of the district. In wildland fire scenarios, time is most valuable in the first minutes of an incident. A truck that can arrive, establish a two-way water supply, and begin an initial attack from an advantageous position often sets the trajectory for the entire response. The learning curve embedded in the fleet rests on the ability to calibrate these vehicles to the landscapes they will traverse, from volcanic soils and pine needles to rocky ridges and steep canyons. This calibration also encompasses maintenance and readiness: crews perform proactive checks and routine maintenance to minimize downtime, ensuring that each vehicle is ready to roll when a smoke plume appears on the horizon.

The conversation about these specialized trucks is incomplete without acknowledging the design insights that inform ongoing improvements. For readers exploring how pumper fire trucks are configured for maximum efficiency, the topic is explored in depth in dedicated design discussions that examine how capacity, weight distribution, pump efficiency, and operator ergonomics interact on the fire line. For a concise look at practical design considerations across the fleet, see the article focused on pumper fire truck design insights. pumper-fire-truck-design-insights. This reference helps connect the field realities described here with the broader practice of firefighting vehicle design, underscoring how even in remote forests, the same engineering principles that guide urban fire apparatus shape the tools used to guard wildlands and communities.

The Forest Service’s firefighting fleet, with its spectrum of specialized trucks, is more than a set of machines. It is a carefully integrated system built to address ecological realities, operational demands, and community protection goals. It reflects a balance between agility and endurance, between suppression capability and terrain compatibility, and between on-site action and the logistical scaffolding that keeps crews effective in austere environments. As each fire season unfolds, these vehicles embody the discipline of preparedness, rigid maintenance schedules, consistent readiness checks, and a culture of rapid deployment. They are barely a century old but have evolved with the forests they serve, continuously adapting to wetter seasons, drier climates, and shifting fire regimes. In the hands of trained personnel, these trucks become more than conveyances; they are platforms for strategic action, enabling responders to reach, assess, and influence a blaze before it transforms a landscape or threatens a life. The result is a fleet that stays true to its mission: to protect forests, watersheds, wildlife habitats, and the communities that depend on them, even when the route to the fire line is steep, rocky, and far from the nearest hydrant.

External resource: For more detailed specifications and operational guidelines on these specialized firefighting trucks, refer to the official U.S. Forest Service Fire Management page. https://www.fs.usda.gov/managing-land/fire

null

null

Rugged Workhorses on Forest Roads: The Durable, Off-Road Fleet Behind Forest Service Missions

On forest roads, the view isn’t just trees and sky; it’s a fleet of rugged machines built for endurance. The U.S. Forest Service depends on a backbone of 4×4 utility trucks that perform a broad spectrum of tasks—from routine patrol and trail maintenance to wildfire suppression support and the transport of crews and gear. These vehicles are not showroom stars; they are field-tested workhorses designed to survive mud, dust, steep grades, and long days in remote places. Their durability rests on a deliberate blend of robust construction, reinforced suspensions, high ground clearance, and powertrains tuned for torque and stamina. They are made not for speed but for steadiness, reliability, and the moment when minutes matter most.

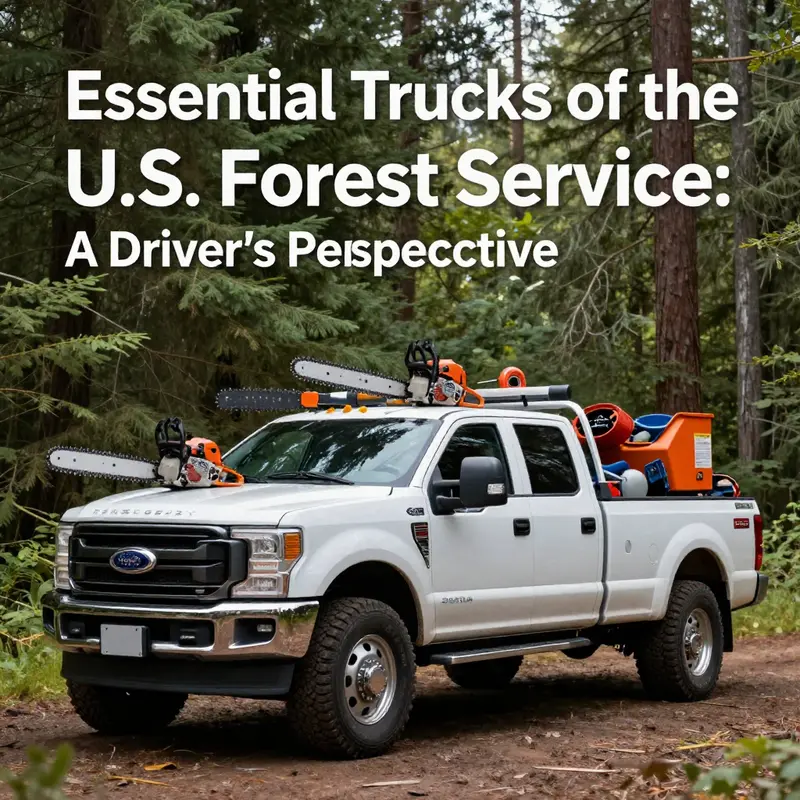

Beyond the utility units, the fleet includes specialized firefighting trucks that play a decisive role when flame and wind demand swift, coordinated action. Fire engines deliver water directly to the fire scene and must do so repeatedly while engines and pumps operate under heat and dust. Water tenders ferry large quantities of water to remote sites where hydrants do not exist, coping with long legs of hose and heavy loads. Wildland Fire Engines (WFEs), engineered for rough terrain, combine four-wheel drive with high ground clearance to navigate rocky trails and uneven terrain while carrying crews and gear into the heart of a blaze. In the same family, utility and work trucks haul forestry equipment—chainsaws, grapples, winches, and tool racks—that crews rely on to cut a path through brush, stabilize a scene, or lift heavy materials. Together, these configurations form a layered toolkit, each vehicle type built to a common standard of durability, simplicity, and field-readiness, so the fleet can adapt quickly to shifting priorities on the ground.

The defining features of Forest Service trucks are not fancy bells and whistles but the fundamentals of performance under stress. Robust construction ensures the frame and body withstand years of exposure to vibration, off-camber surfaces, and sudden jolts from rough roads. Reinforced suspensions provide stability and control when negotiating potholes, washouts, or rutted mountain tracks. High ground clearance prevents underbody damage when a truck must crawl over fallen logs or cross stone crossings. A powerful drivetrain delivers torque where it is needed most—for steady climbs, heavy pulls up grades, and confident towing of trailers and equipment in less-than-ideal conditions. Cooling systems are sized for long runs in hot weather or sustained operation during an incident, a critical detail that prevents overheating when pumps run and air does not circulate freely in the cabin. The goal is reliability through design: parts that can be inspected and replaced in the field, systems that tolerate dusty environments, and components that do not fail when a vehicle is asked to perform multiple duties in a single shift.

In practice, the application intensity of forest service missions is a defining difference from typical road work. These trucks may spend hours on patrol routes that resemble backcountry lanes, then pivot to carry heavy tool kits and chainsaw crews into a remote firebreak, and finally serve as a mobile command post or shelter for personnel. That versatility is reflected in the way configurations are chosen and maintained. A 4×4 utility chassis might serve as the platform for different body builds depending on the season or incident type. The same base frame can house equipment for maintenance, emergency response, or incident command without requiring a comprehensive rebuild each time. This modularity reduces downtime and extends useful life, key considerations when budgets must stretch across a wide geographic area and a long fire season. Maintenance programs emphasize routine checks of the chassis, driveline, braking, and cooling systems, along with seasonal preparations for winter weather where frozen water lines and snow-laden roads test the durability of every component. Training staff to perform preventive maintenance in the field is part of ensuring readiness, so a minor issue never becomes a mission-critical failure in a distant district.

The mechanical performance of these vehicles—without naming individual models—rests on a careful balance between capacity and resilience. Heavy-duty frames and axles support substantial payloads, while rugged suspensions absorb shocks from uneven surfaces so the crew remains safe and the equipment stays secure. The emphasis on torque at low speeds is deliberate; it allows a vehicle to maneuver through steep, slick, or soft terrain with a loaded body, and to maneuver around fallen trees or debris that block a track. Four-wheel drive works in concert with braking and traction-control systems to keep grip on mud, gravel, or rocky surfaces where a smooth ride is not the measure of success but the ability to arrive on site with intact cargo. The Fleet’s reliability is further ensured by design choices that favor long service life, straightforward maintenance, and the capacity to operate in remote locations without frequent refueling or complicated repairs. In practical terms, that translates to a vehicle that can haul gear, tow a trailer, run a generator, and run lights through a long night of monitoring, all while remaining capable of covering dozens or hundreds of miles of sometimes harsh terrain.

Despite the breadth of tasks and the variability of terrains, the guiding principle remains consistent: these trucks must perform day after day in some of the most unforgiving environments. They are not about marketing appeal; they are about field-proven utility and the assurance that a crew can reach people in need, deliver water or tools, and stabilize a scene with confidence. Districts tailor their fleets by adjusting payloads, body configurations, and storage solutions to fit the local topography and incident history. The result is a cohesive, resilient fleet that shares a common DNA of durability, off-road agility, and practical design—one that can pivot quickly from routine maintenance to a high-stakes emergency without breaking stride.

For readers who want to dig deeper into the engineering backdrop and procurement currents shaping these trucks, there is a broader conversation about fire apparatus procurement strategies. The emphasis is on durability, interoperability, lifecycle costs, and the ability to keep assets ready for years of field service. The focus is not on choosing a single model but on selecting platforms and bodies that can perform under the same core conditions across diverse districts. In the end, the Forest Service’s truck fleet reflects a pragmatic philosophy: build for the long haul, keep the fleet uniform enough to simplify maintenance and training, and preserve the flexibility to reconfigure quickly as needs shift with seasons and fires. This approach is what enables crews to reach remote parts of the forest, support critical operations, and stand ready to respond to the next call with confidence.

External resource and citation: For a deeper dive into engineering specifics and buyer guidance on heavy-duty trucks, readers may consult an external resource such as a major manufacturer’s used-truck buyers guide, which outlines durability benchmarks, payload and towing considerations, and the lifecycle implications of heavy-duty platforms. External reference: https://www.ford.com/trucks/used-truck-buyers-guide/

Internal link: For procurement considerations in the field, see fire-apparatus procurement.

Regional Tailoring of Forest Service Trucks: How Terrain, Climate, and Fire Shape a National Fleet

The forest system’s fleet is not a one-size-fits-all collection of vehicles. It is a carefully tailored mosaic, designed to meet the diverse demands of wildland management across America’s wide and varied landscapes. From the fog-washed passes of the Pacific Northwest to the sunburned plains of the Great Plains, and from the dry canyons of the Southwest to the high desert plateaus of the Intermountain West, region-specific conditions drive decisions about drivetrain, suspension, payloads, water carry capacity, and even the tools stowed in the boxes. The result is a coherent national capability that remains flexible enough to handle routine patrols, trail maintenance, and rapid-fire incidents with the same underlying emphasis on durability, reliability, and rapid response. In each region, the trucks are not merely transport; they are mobile workshops and first-arrival platforms that connect ground crews to the larger suppression network. They must be able to navigate unpaved, rutted, and sometimes washed-out forest roads, while carrying the gear and personnel needed to begin an effective response long before larger engines or aircraft arrive on scene. The practical implications of regional variation begin with the basics of terrain and climate, and radiate outward to affect configurations for water, pumps, tools, and even the way crews are trained to use the vehicles on a daily basis.

In the Pacific Northwest, the natural theatre is rugged, timber-dense, and often shrouded in moisture that can rapidly give way to slick, steep trails. Trucks deployed here prioritize four-wheel-drive capability, robust suspension, and high ground clearance to maintain traction on steep, uneven forest roads and when crossing wet ruts after long rains or spring thaws. The goal in this region is to keep responders mobile in terrain where a single off-road obstacle can slow an entire incident timeline. Cargo space is organized to support both routine forest management tasks and suppression activities, with compartments arranged for rapid access to chainsaw tools, grappling hooks, and field communications gear. The emphasis is on reliability under harsh, damp conditions, and on the ability to operate effectively in remote pullouts where water and fuel supplies are modest and distance to a fire line matters. Even with a focus on rugged mobility, crews in the Pacific Northwest must be ready for rapid shifts in weather that can transform a routine patrol into a high-alert incident in a matter of hours.

To the east, the Great Plains present a different calculus. The flat, expansive landscape can give rise to fast-moving grass and brush fires that race with the wind. In this environment, trucks are chosen for a balance between road speed, water-carrying capacity, and the ability to reach remote sites quickly along long corridors of rural road and dirt farm-to-forest connectors. Here, the emphasis often tilts toward maximizing on-road speed and improving access to the driest, most distant camera points, while still maintaining off-road capability for rural fire breaks and remote water sources. The butts and booms of suppression equipment must be complemented by enough weight behind the cab to ensure stability on grade changes and to handle long-distance transport of personnel and equipment across prairie micro-terrain. Utility and all-terrain variants come into play, equipped to shuttle portable pumps and hand tools to an initial attack site while awaiting larger engines from more central locations. This regional mindset ensures that initial attack operations are not constrained by the first miles of travel, but rather begin on arrival at the edge of the burn, with the right tools already in place.

In the Southwest, the fire environment grows more complex still. Crown fires, dense timber, and the harsh, arid climate combine to demand heavy-duty pumps, robust water delivery capability, and even more resilience in vehicle design. Engines in this region often feature advanced capabilities for aerial water delivery at longer distances, along with heavier-duty pump packages that can sustain long punching streams through challenging terrain. The vehicles also incorporate storage and mounting systems for weathered terrain gear, quick-attach tools, and protective equipment that must perform reliably in heat and dust. The design philosophy here leans into endurance and versatility: a chassis that can haul substantial water or be tightly integrated with a portable water shuttle, while also staying nimble enough to maneuver within pine stands and along canyon roads. In areas with low fuel availability and rugged access, response teams rely on utility units capable of supporting initial attack with hand tools and portable pumps until larger resources can reach the scene.

The Intermountain West adds still further nuance. Remote, canyon-dotted landscapes, coupled with sparse infrastructure, mean that fleets here must emphasize reach, flexibility, and field practicality. Utility and all-terrain trucks that can traverse rocky, narrow byways without becoming stuck are favored for access to isolated burn sites where a traditional mainline engine might struggle to reach. In these districts, crews routinely carry portable pump kits, hand tools for line construction, and equipment for rapid preliminary assessment—tools that allow ground personnel to establish a defensible location and begin suppression work while awaiting air support or larger ground forces. The vehicles serve as mobile workstations, with organized storage for radios, maps, and essential rescue gear, and as reliable, predictable platforms for crew changeouts that can stretch across long shifts in challenging environments.

Across these regions, the common thread is a deliberate tailoring of the fleet to fit the geography and the fire behavior typical of the local ecosystem. The same basic categories appear in every district—a 4×4 utility platform for general operations, heavy-duty engines and water tenders for sustained suppression, and specialized all-terrain or utility trucks for remote initial attack—and yet the specific configurations vary to reflect daily realities. The underlying philosophy is not to chase the newest gadget or to chase uniformity for its own sake, but to build a fleet that can be counted on in the moment when a flame front arrives in a way that is detectable, manageable, and ultimately less destructive. The stewardship of such a fleet rests on ongoing fleet management decisions that balance lifecycle costs, maintenance demands, and the mission-critical need for uptime. A well-used forest road might be carved into mud one afternoon, and a dry, dusty pass the next, so the same vehicle must perform across those extremes with predictable results. That requires attention to routine maintenance, robust after-sales support, and simple, field-tested configurations that crews can learn quickly and apply under pressure.

In practice, regional adaptation also extends to how vehicles are loaded for field operations. Vehicles in wetter climates may carry extra ground-fault protection and weatherproofing along with gear that resists mildew and corrosion. In arid or dusty regions, seals and air filters are chosen to endure harsher particulate exposure, and storage systems emphasize ease of cleaning. The avoidance of overcomplication is a classic principle here: the best regional design is one that minimizes the number of steps a crewmember must take to reach essential tools, to connect a portable pump, or to reconfigure compartments for a different mission—whether it is a routine patrol, a line-building operation, or a fast, on-the-ground response to a sudden flare-up.

The thread that runs through all of this is a data-informed approach to fleet composition and procurement. Regional fire managers collaborate with fleet coordinators to monitor incident patterns, road conditions, and climate trends. They weigh the practical realities of dispatch centers, reconnaissance teams, and on-site crews who may end up working with the same truck for many seasons. The near-universal goal is to maintain high uptime and predictable performance across a diverse geography, so that when a wildfire starts, the fleet is not a liability but a force multiplier. Given the vastness of the country and the diversity of landscapes, this regional tailoring is more than a matter of preference; it is a necessity for effective suppression and safe, transferable operations across districts.

For readers seeking more on how firefighting apparatus is designed, managed, and supported in this field, see the deeper discussions in this session on pumper-fire-truck-design-insights. The approach there aligns with the Forest Service’s own emphasis on reliability, uptime, and regional adaptability, offering practical perspectives on how fleets are planned, configured, and maintained to meet complex, real-world demands. Additionally, broad perspectives from fire management resources underscore how these regional differences fit into a larger national strategy that prioritizes rapid response, tactical flexibility, and sustainable fleet stewardship. External references provide further context on the Forest Service’s fire-management framework and the ways in which regional planning informs fleet choices and deployment with a view toward long-term resilience.

External resource: https://www.fs.usda.gov/managing-land/fire

Final thoughts

Understanding the diverse trucks used by the U.S. Forest Service not only highlights the adaptability and functionality of these vehicles but also showcases their vital role in maintaining our national forests and responding to emergencies. Each truck is designed for a specific purpose, ensuring that crews remain prepared for any situation. As professionals in the trucking industry, recognizing the unique requirements and specifications of these trucks can lend valuable perspectives that may enhance operational strategies in the commercial sector. Ultimately, these vehicles represent a commitment to safety, efficiency, and resilience in some of the most demanding environments.