In the realm of emergency response, the design and functionality of pumper fire trucks are paramount. These vehicles are often the first to arrive at the scene of a fire, and their preparedness can mean the difference between life and death. A well-considered pumper fire truck design not only optimizes the performance of firefighting operations but also enhances firefighter safety and efficiency. From sophisticated pump capacities to strategic compartment configurations, every detail must be meticulously crafted to ensure quick and effective responses in critical situations.

Pumper fire trucks embody the blend of engineering excellence and real-world practicality, reflecting the unique operational needs of fire departments. As we delve into the essential components and operational considerations in pumper fire truck design, we explore how these factors converge to strengthen emergency responses and ultimately safeguard lives and property.

The global pumper fire truck market is exhibiting remarkable growth. Here are some important statistics:

- It is projected to surpass USD 6 billion by 2034.

- Pumper fire trucks account for over 40% of the entire fire truck market share as of 2024.

- This growth emphasizes the crucial role that pumper fire trucks play in emergency situations.

Design Trends

There are notable shifts in design preferences among fire departments, focusing on advanced features. Key trends include:

- Digital Systems: Integration of GPS tracking and real-time diagnostics for monitoring and maintenance.

- Lightweight Materials: Increased use improves fuel efficiency and payload capacity.

- Sustainable Solutions: Introduction of all-electric models by companies such as Rosenbauer.

Budget Considerations

Budget constraints are leading fire departments to seek cost-effective solutions. This includes:

- Emphasis on budget-friendly pumper trucks that don’t sacrifice performance.

- Strategies like fleet standardization to streamline operations and reduce long-term costs, enhancing training consistency.

Continued Relevance

Despite evolving technologies and economic shifts, pumper fire trucks maintain their essential role by:

- Functioning as dual-purpose vehicles for water transport and supply during firefighting.

- Adapting to both urban and rural settings, reinforcing their importance in community safety.

In summary, recent trends indicate a robust increase in the adoption of pumper fire trucks, driven by technological advancements, budget-conscious acquisitions, and their crucial role in effective fire response strategies.

| Manufacturer | Pump Capacity (GPM) | Water Tank Size (Gallons) | Chassis Type | Foam System Type |

|---|---|---|---|---|

| Pierce Manufacturing | 1,000 – 2,000 | 500 – 1,500 | Custom Chassis | Class A Foam System |

| Oshkosh Corporation | 1,250 – 2,500 | 750 – 1,500 | Heavy-Duty Chassis | Integrated Foam System |

| Rosenbauer | 1,250 – 3,000 | 500 – 2,000 | Custom Chassis | Compressed Air Foam System |

| E-One | 1,000 – 2,000 | 500 – 1,250 | Customizable Chassis | Class B Foam System |

| Spartan Emergency Vehicles | 1,000 – 2,000 | 500 – 1,000 | Freightliner Chassis | Manual Foam System |

| Manufacturer | Pump Capacity (GPM) | Water Tank Size (Gallons) | Chassis Type | Foam System Type |

|---|---|---|---|---|

| Pierce Manufacturing | 1,000 – 2,000 | 500 – 1,500 | Custom Chassis | Class A Foam System |

| Oshkosh Corporation | 1,250 – 2,500 | 750 – 1,500 | Heavy-Duty Chassis | Integrated Foam System |

| Rosenbauer | 1,250 – 3,000 | 500 – 2,000 | Custom Chassis | Compressed Air Foam System |

| E-One | 1,000 – 2,000 | 500 – 1,250 | Customizable Chassis | Class B Foam System |

| Spartan Emergency Vehicles | 1,000 – 2,000 | 500 – 1,000 | Freightliner Chassis | Manual Foam System |

Pump Capacity and Specifications

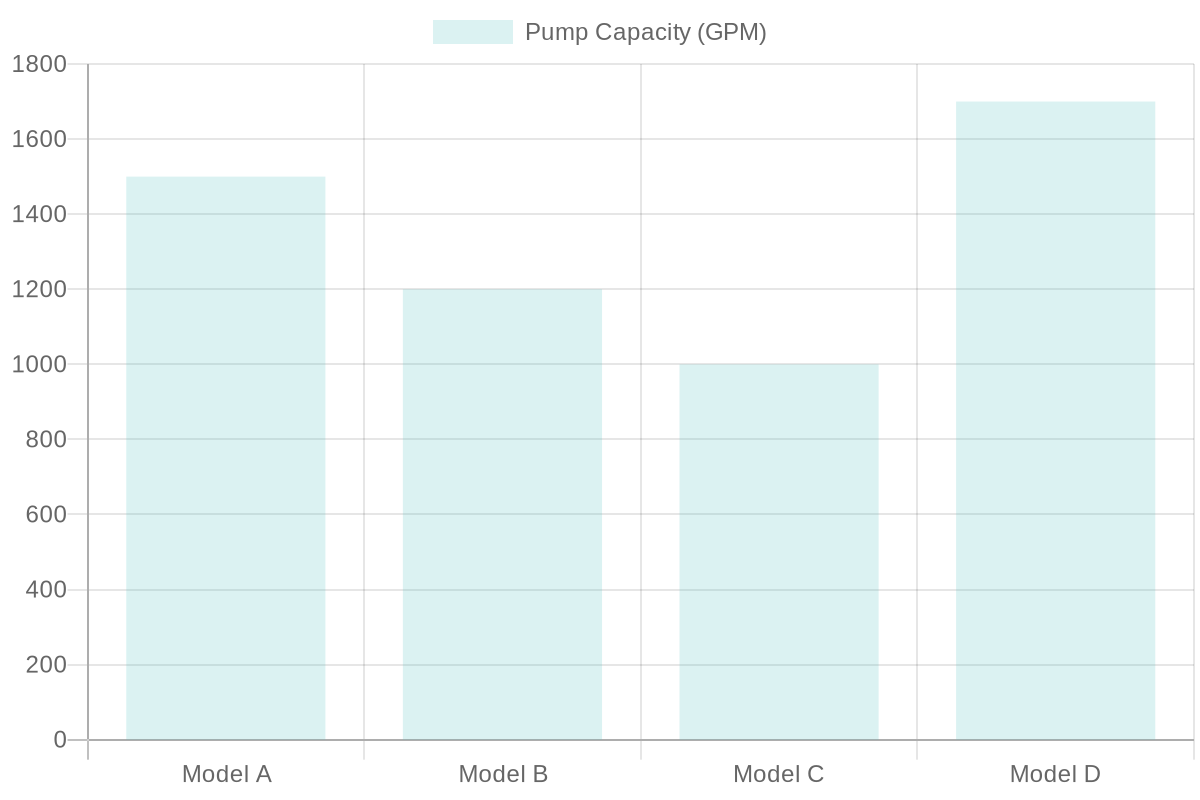

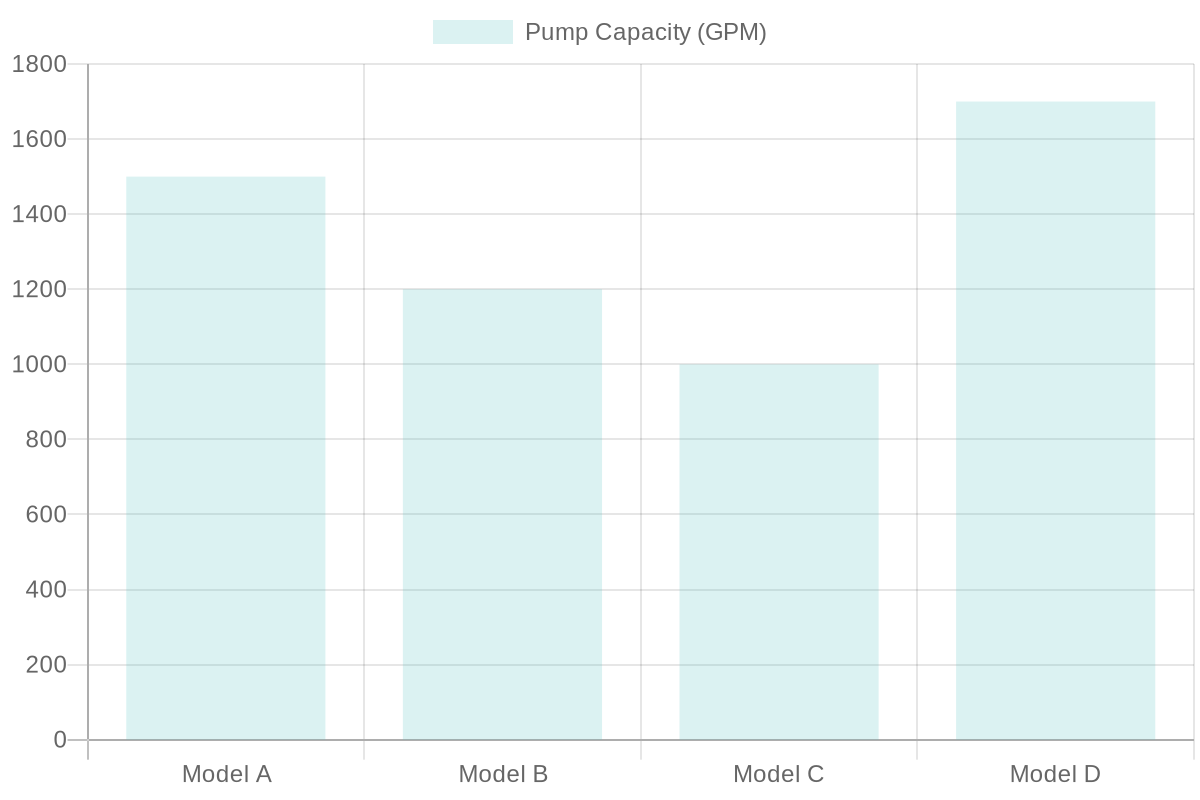

In the realm of pumper fire trucks, the range of pump capacities typically varies from 500 to 3,000 gallons per minute (GPM). This variation plays a crucial role in a fire department’s operational efficiency and its ability to supply water during emergencies. When determining the appropriate pump capacity, departments must consider factors such as the geographic characteristics of their service area, the nature of potential incidents, and existing infrastructure.

For urban fire departments, high-capacity pumps of around 2,500 to 3,000 GPM can effectively manage the demands of larger structures, such as skyscrapers, where substantial water flow is necessary to combat extensive fire spread. For example, the Greenfield Fire District in Saratoga Springs, NY, operates a fleet that includes two 1,500 GPM pumps, which allows them to extinguish fires more efficiently and minimizes monetary losses for property owners (source: Firehouse) while the Baltimore City Fire Department utilizes engines with 1,500 GPM pumps to meet their operational needs (piercemfg.com).

Conversely, rural departments may opt for lower capacities, focusing instead on carrying sufficient water supply in tanks, like those used by the Prince William County Fire & Rescue System, which utilizes 1,500 GPM pumps alongside 750-gallon water tanks. This configuration enables them to target fire flows ranging from 150 to 1,000 GPM, making them adaptable for various emergency scenarios (source: Firehouse). In such instances, maintaining high flow rates can be challenging, especially during defensive operations where required flows may exceed 2,000 GPM, necessitating careful planning and coordination between multiple water sources (source: Firehouse).

Moreover, strategic water supply planning is essential to ensure adequate flow capabilities during emergencies. The Insurance Services Office (ISO) guidelines recommend maintaining adequate capacities to fulfill demands of 2,500 GPM for two hours or up to 3,500 GPM for longer durations (source: ISO Mitigation). This underscores the importance of aligning pump specifications with both operational effectiveness and water distribution system capabilities, ensuring no response is impeded by inadequate water supply.

In conclusion, understanding the specifications of pump capacities ranging from 500 to 3,000 GPM allows fire departments to better prepare for the diverse demands of emergency responses, balancing efficiency with the need for sufficient water supply capabilities. Each department must evaluate its unique responses to emergencies, choosing the right pump specifications that align with both infrastructure and operational needs.

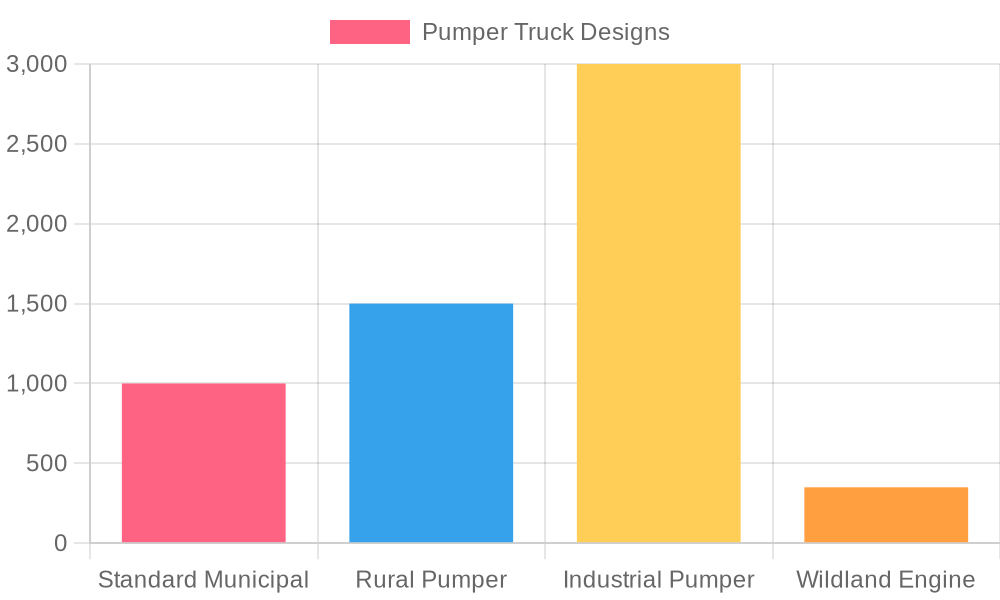

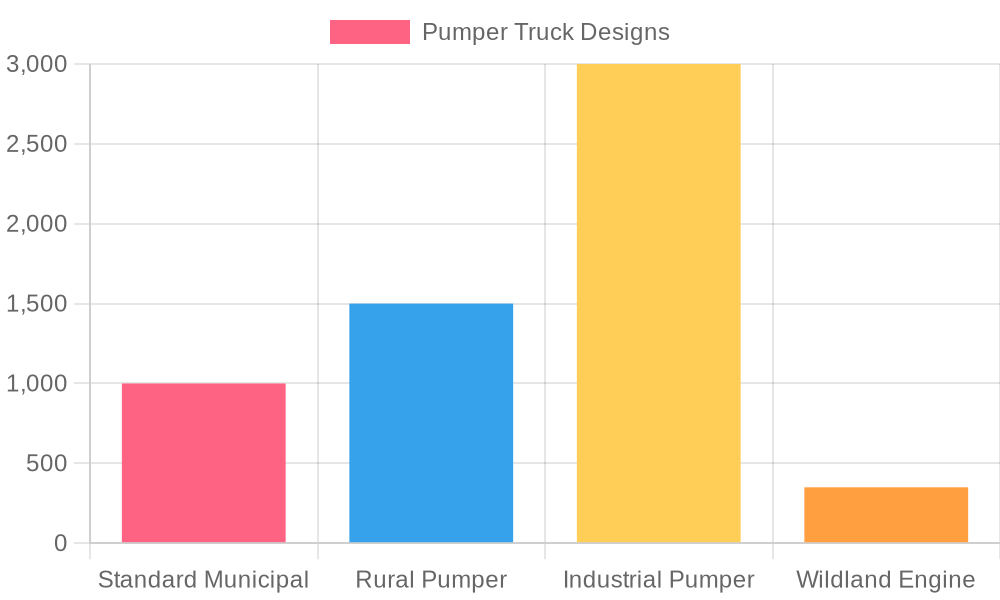

This chart illustrates average response times for various pumper truck designs based on their pump capacities and water tank sizes. It highlights how different design variables can impact overall response efficiency, providing valuable insights for fire departments in optimizing their operational strategies.

Storage Organization and Compartments

Effective storage organization within pumper fire trucks is paramount for ensuring that firefighters can respond swiftly and efficiently during emergencies. The configuration of compartments significantly impacts operational effectiveness, allowing for optimal storage of firefighting tools, equipment, and hoses. Key features of storage organization include:

Compartment Design

The compartments within a pumper fire truck should be designed with accessibility and efficiency in mind. Different sizes and layouts allow for the effective storage of specialized equipment, firefighting gear, and hoses. For example, modular compartments can be tailored to fit specific gear, minimizing clutter and enabling quick retrieval of necessary items. This design is crucial in keeping vital equipment easily accessible during high-pressure situations where time is of the essence.

Hosebed Height

Hosebed height is another critical feature to consider. It should be designed for quick access so that firefighters can deploy hoses rapidly during operations. The optimal hosebed height typically allows personnel to load and unload hoses without excessive stretching or bending, reducing strain and increasing efficiency. Ideally, the hosebed should also include features like grab handles to facilitate swift handling during emergencies.

Tips for Maximizing Efficiency

To maximize the benefits of storage organization, fire departments can consider the following recommendations:

- Color Coding: Assign colors to different compartments or types of equipment, enabling crews to quickly identify where specific items are stored at a glance.

- Modular Storage Solutions: Use modular organization systems that allow for adaptable storage in compartments. This helps accommodate various equipment sizes and can be customized for specific missions.

- Training and Familiarization: Regular training sessions can ensure that all crew members know where equipment is located and how to access it efficiently. Conduct practice drills to enhance retrieval speed under pressure.

- Regular Maintenance Checks: Schedule routine organization reviews to replace worn-out items and ensure that all equipment is in its designated place. A disorganized compartment can lead to delays during emergencies.

By implementing effective storage organization strategies, fire departments can improve their operational efficiency, decrease response times, and ultimately enhance firefighter safety. Tailoring the pumper fire truck’s design to meet the specific needs of firefighting operations plays a critical role in responding to emergencies with confidence and speed.

In conclusion, the careful planning of storage and compartments is essential for optimizing the performance of pumper fire trucks in the field. As the demands of firefighting continue to evolve, embracing innovative organization techniques will undoubtedly contribute to successful emergency management.

In conclusion, the design of pumper fire trucks encompasses various essential components and operational considerations that significantly impact fire departments’ efficiency and effectiveness in emergency situations. From pump capacity and water tank size to storage organization and safety features, every detail must be carefully assessed. The importance of tailoring approaches to each department’s unique needs cannot be overstated. By recognizing the specific conditions and expectations of the environments in which they operate, fire departments can optimize their pumper truck designs for enhanced performance. As you consider the design process for your department’s apparatus, reflect on your operational requirements and engage in thorough discussions with stakeholders. This ensures that the final outcome is a well-equipped pumper fire truck, ready to meet the challenges of firefighting head-on.

In conclusion, the significance of pumper fire truck design cannot be underestimated in the realm of emergency response. It is essential to recognize that each fire department operates under unique circumstances and faces distinct challenges during firefighting operations. Therefore, customizing pumper fire trucks based on these operational needs is crucial. Effective design enhances not only the functionality of equipment but also the safety of firefighters. From ensuring optimal hose placement to maximizing pump capacity, every design element plays a pivotal role in delivering a quick and effective response to emergencies. By investing in thoughtful pumper fire truck design, fire departments can improve their readiness and make a substantial impact on safeguarding lives and property during critical situations. Ultimately, a well-designed pumper fire truck is not just a piece of equipment; it is a lifeline that can make all the difference in emergency response scenarios.

Design Process and Operational Planning

The design process of a pumper fire truck is a complex endeavor that necessitates meticulous consideration of various operational factors. As articulated, “Designing a pumper means making choices which directly reflect a department’s specific operations.” This sentiment underscores the critical nature of aligning the design features with the unique demands of firefighting environments.

Moreover, developing the right apparatus starts with a foundational principle: “Developing the right apparatus starts with asking the right questions.” Engaging in thorough discussions about the specific needs of a fire department is paramount. Questions like, “How often do we encounter scenarios that require specific equipment?” and “What unique geographical challenges do we face?” are vital in crafting a design that is both functional and efficient.

Historically, response data has shown how various tools have been actualized in real-world scenarios: “Historically, response data showed which tools were actually needed, how often water supply delays occurred and where equipment placement slowed operations down.” Such insights can illuminate decision-making processes during the design phase, where clear communication with stakeholders leads to informed choices that enhance overall operational effectiveness.

Integrating these considerations into the design of pumper fire trucks not only optimizes performance during emergencies but also reinforces the importance of strategic planning in achieving those outcomes. By ensuring that designs correspond closely to operational needs, fire departments can enhance their readiness and responsiveness in critical situations.

Design Process and Operational Planning

The design process of a pumper fire truck is a complex endeavor that necessitates meticulous consideration of various operational factors. As articulated, “Designing a pumper means making choices which directly reflect a department’s specific operations.” This sentiment underscores the critical nature of aligning the design features with the unique demands of firefighting environments.

Moreover, developing the right apparatus starts with a foundational principle: “Developing the right apparatus starts with asking the right questions.” Engaging in thorough discussions about the specific needs of a fire department is paramount. Questions like, “How often do we encounter scenarios that require specific equipment?” and “What unique geographical challenges do we face?” are vital in crafting a design that is both functional and efficient.

Historically, response data has shown how various tools have been actualized in real-world scenarios: “Historically, response data showed which tools were actually needed, how often water supply delays occurred and where equipment placement slowed operations down.” Such insights can illuminate decision-making processes during the design phase, where clear communication with stakeholders leads to informed choices that enhance overall operational effectiveness.

Integrating these considerations into the design of pumper fire trucks not only optimizes performance during emergencies but also reinforces the importance of strategic planning in achieving those outcomes. By ensuring that designs correspond closely to operational needs, fire departments can enhance their readiness and responsiveness in critical situations.

Insights on Firefighter Safety Features in Pumper Fire Truck Designs

Incorporating advanced safety features into pumper fire truck designs is crucial for protecting firefighters and enhancing operational outcomes during emergency situations. Key safety features include:

-

Electronic Stability Control (ESC): ESC systems help maintain vehicle stability by detecting and correcting understeer or oversteer conditions, reducing the risk of rollovers—a common hazard due to the high center of gravity in fire apparatus.

[Source] -

Advanced Seatbelt and Airbag Systems: Modern fire trucks are equipped with seatbelt sensors that alert when occupants are unbelted, pre-tensioning seatbelts that tighten during potential rollover scenarios, and comprehensive airbag systems—including frontal, side, and under-dash airbags—to protect occupants from various collision impacts.

[Source] -

Enhanced Visibility and Lighting: LED lighting arrays improve visibility during nighttime or low-visibility operations, while high-visibility markings and reflective striping enhance recognition by other road users, reducing accident risks during emergency responses.

[Source] -

Ergonomic Cab Design: Ergonomically designed crew cabins with shock-absorbing seats, adjustable controls, and climate control systems reduce firefighter fatigue and physical strain, contributing to safer and more effective operations.

[Source] -

Advanced Communication and Monitoring Systems: Integration of real-time navigation, GPS optimization, and telematics platforms allows for efficient route planning, continuous connectivity, and vehicle health monitoring, ensuring timely responses and reducing the likelihood of mechanical failures during critical operations.

[Source]

Implementing these safety features not only protects firefighters from potential hazards but also enhances the overall efficiency and effectiveness of emergency response operations.

This image highlights the importance of pump capacities and specifications in firefighting operations, demonstrating how different pump capacities can impact firefighting efficiency. It visually represents features like pump ratings and their operational significance in emergency response scenarios.

Design Process and Operational Planning

The design process of a pumper fire truck is a complex endeavor that necessitates meticulous consideration of various operational factors. As articulated, “Designing a pumper means making choices that directly reflect a department’s specific operations.” This sentiment underscores the critical nature of aligning the design features with the unique demands of firefighting environments.

Moreover, developing the right apparatus starts with a foundational principle: “Developing the right apparatus starts with asking the right questions.” Engaging in thorough discussions about the specific needs of a fire department is paramount. Questions like, “How often do we encounter scenarios that require specific equipment?” and “What unique geographical challenges do we face?” are vital in crafting a design that is both functional and efficient.

Historically, response data has shown how various tools have been actualized in real-world scenarios: “Historically, response data showed which tools were actually needed, how often water supply delays occurred and where equipment placement slowed operations down.” Such insights can illuminate decision-making processes during the design phase, where clear communication with stakeholders leads to informed choices that enhance overall operational effectiveness.

Integrating these considerations into the design of pumper fire trucks not only optimizes performance during emergencies but also reinforces the importance of strategic planning in achieving those outcomes. By ensuring that designs correspond closely to operational needs, fire departments can enhance their readiness and responsiveness in critical situations.

Insights on Firefighter Safety Features in Pumper Fire Truck Designs

Incorporating advanced safety features into pumper fire truck designs is crucial for protecting firefighters and enhancing operational outcomes during emergency situations. Key safety features include:

- Electronic Stability Control (ESC): ESC systems help maintain vehicle stability by detecting and correcting understeer or oversteer conditions, reducing the risk of rollovers—a common hazard due to the high center of gravity in fire apparatus. (firerescue1.com)

- Advanced Seatbelt and Airbag Systems: Modern fire trucks are equipped with seatbelt sensors that alert when occupants are unbelted, pre-tensioning seatbelts that tighten during potential rollover scenarios, and comprehensive airbag systems—including frontal, side, and under-dash airbags—to protect occupants from various collision impacts. (firerescue1.com)

- Enhanced Visibility and Lighting: LED lighting arrays improve visibility during nighttime or low-visibility operations, while high-visibility markings and reflective striping enhance recognition by other road users, reducing accident risks during emergency responses. (yongansafety.com)

- Ergonomic Cab Design: Ergonomically designed crew cabins with shock-absorbing seats, adjustable controls, and climate control systems reduce firefighter fatigue and physical strain, contributing to safer and more effective operations. (yongansafety.com)

- Advanced Communication and Monitoring Systems: Integration of real-time navigation, GPS optimization, and telematics platforms allows for efficient route planning, continuous connectivity, and vehicle health monitoring, ensuring timely responses and reducing the likelihood of mechanical failures during critical operations. (yongansafety.com)

Implementing these safety features not only protects firefighters from potential hazards but also enhances the overall efficiency and effectiveness of emergency response operations.

Storage Organization and Compartments

Effective storage organization within pumper fire trucks is paramount for ensuring that firefighters can respond swiftly and efficiently during emergencies. The configuration of compartments significantly impacts operational effectiveness, allowing for optimal storage of firefighting tools, equipment, and hoses. Key features of storage organization include:

Compartment Design

The compartments within a pumper fire truck should be designed with accessibility and efficiency in mind. Different sizes and layouts allow for the effective storage of specialized equipment, firefighting gear, and hoses. For example, modular compartments can be tailored to fit specific gear, minimizing clutter and enabling quick retrieval of necessary items. This design is crucial in keeping vital equipment easily accessible during high-pressure situations where time is of the essence.

Hosebed Height

Hosebed height is another critical feature to consider. It should be designed for quick access so that firefighters can deploy hoses rapidly during operations. The optimal hosebed height typically allows personnel to load and unload hoses without excessive stretching or bending, reducing strain and increasing efficiency. Ideally, the hosebed should also include features like grab handles to facilitate swift handling during emergencies.

Tips for Maximizing Efficiency

To maximize the benefits of storage organization, fire departments can consider the following recommendations:

- Color Coding: Assign colors to different compartments or types of equipment, enabling crews to quickly identify where specific items are stored at a glance.

- Modular Storage Solutions: Use modular organization systems that allow for adaptable storage in compartments. This helps accommodate various equipment sizes and can be customized for specific missions.

- Training and Familiarization: Regular training sessions can ensure that all crew members know where equipment is located and how to access it efficiently. Conduct practice drills to enhance retrieval speed under pressure.

- Regular Maintenance Checks: Schedule routine organization reviews to replace worn-out items and ensure that all equipment is in its designated place. A disorganized compartment can lead to delays during emergencies.

By implementing effective storage organization strategies, fire departments can improve their operational efficiency, decrease response times, and ultimately enhance firefighter safety. Tailoring the pumper fire truck’s design to meet the specific needs of firefighting operations plays a critical role in responding to emergencies with confidence and speed.

Insights on Emergency Response Vehicles and Fire Department Equipment

Recent advancements in emergency response vehicles and fire department equipment have significantly enhanced the efficiency and effectiveness of modern firefighting operations.

Integration of Advanced Technologies in Fire Trucks

Modern fire trucks are now equipped with advanced technologies that improve response times and operational safety. Features such as real-time GPS navigation systems help firefighters navigate urban traffic efficiently, ensuring prompt arrival at emergency scenes. Additionally, sophisticated communication networks, including digital radios and satellite communication, facilitate seamless coordination during emergencies. Enhanced pumping systems with electronically controlled pumps allow precise water pressure adjustments, optimizing fire suppression efforts. Ergonomically designed crew cabins and advanced lighting systems further contribute to firefighter safety and operational efficiency. (yongansafety.com)

Adoption of Electric Fire Trucks

The introduction of electric fire trucks marks a significant step toward sustainable firefighting solutions. For instance, Rosenbauer has developed the first fully operational electric fire truck in the U.S., featuring traditional firefighting equipment alongside a battery life of approximately two hours. While the cost is higher than conventional engines, the environmental benefits and alignment with electric vehicle fleet goals make them a valuable addition to fire departments. (axios.com)

Transition to Smaller Emergency Response Vehicles

Some fire departments are transitioning to smaller emergency response vehicles to enhance maneuverability and reduce costs. These vehicles are easier to drive, offer faster acceleration and stopping times, and are more cost-effective to purchase and maintain. This shift allows for quicker and more efficient arrival at emergency scenes, particularly in high-traffic areas. (wardapparatus.com)

Implementation of Advanced Fire Apparatus

Fire departments are investing in advanced fire apparatus to bolster their firefighting capabilities. For example, the Santa Rosa Fire Department has acquired state-of-the-art fire apparatus featuring custom cabs with raised roofs, advanced occupant protection systems, high-performance engines, and unique steering systems that enhance maneuverability. These features collectively improve the department’s service levels and operational efficiency. (fireandsafetyjournalamericas.com)

Integration of AI and UAV Technologies

The integration of artificial intelligence (AI) and unmanned aerial vehicles (UAVs) is revolutionizing emergency response. AI-powered systems can monitor environmental damage and provide early intelligence to incident commanders, reducing workload and enhancing decision-making. UAVs equipped with sensors and cameras assist in inspecting hazardous environments, improving safety and operational efficiency. (arxiv.org)

These developments underscore the critical role of modern emergency response vehicles and equipment in enhancing the operational efficiency and effectiveness of fire departments.

This image illustrates modern pumper fire truck designs featuring advanced equipment and emergency response vehicles, showcasing enhanced firefighting capabilities in action.

In conclusion, the significance of pumper fire truck design cannot be underestimated in the realm of emergency response. It is essential to recognize that each fire department operates under unique circumstances and faces distinct challenges during firefighting operations. Therefore, customizing pumper fire trucks based on these operational needs is crucial. Effective design enhances not only the functionality of equipment but also the safety of firefighters. From ensuring optimal hose placement to maximizing pump capacity, every design element plays a pivotal role in delivering a quick and effective response to emergencies. By investing in thoughtful pumper fire truck design, fire departments can improve their readiness and make a substantial impact on safeguarding lives and property during critical situations. Ultimately, a well-designed pumper fire truck is not just a piece of equipment; it is a lifeline that can make all the difference in emergency response scenarios.

Design Process and Safety Features in Pumper Fire Trucks

The design process of a pumper fire truck is a complex endeavor that requires meticulous consideration of various operational factors and the safety of firefighters. As articulated, “Designing a pumper means making choices that directly reflect a department’s specific operations.” This sentiment emphasizes the critical nature of aligning design features with the unique demands of firefighting situations.

Engaging in comprehensive discussions about the specific needs of a fire department is paramount in this process. Questions such as “How often do we encounter scenarios that require specific equipment?” and “What unique geographical challenges do we face?” are essential for crafting a design that is both functional and efficient. Additionally, understanding historical response data provides valuable insights into which tools are necessary, how often delays occur, and where equipment placement can affect operational effectiveness.

Furthermore, incorporating advanced safety features into pumper fire truck designs is crucial for protecting firefighters and enhancing operational outcomes during emergencies. Key safety components include:

- Electronic Stability Control (ESC): This system helps maintain vehicle stability by detecting and correcting understeer or oversteer conditions, lowering rollover risks, which are common given the high center of gravity in fire apparatus.

- Advanced Seatbelt and Airbag Systems: Modern fire trucks feature seatbelt sensors that alert when occupants are unbelted, pre-tensioning systems that tighten during potential rollover scenarios, and comprehensive airbag systems to cushion occupants during collisions.

- Enhanced Visibility and Lighting: LED lighting arrays improve visibility during nighttime operations, while high-visibility markings help other road users recognize fire trucks, reducing accident risks during emergencies.

- Ergonomic Cab Design: Designed to alleviate firefighter fatigue, these cabins include shock-absorbing seats and adjustable controls, contributing to safer and more effective operations.

- Advanced Communication and Monitoring Systems: Integration of real-time navigation, GPS optimization, and telematics ensures timely responses, enhances connectivity, and monitors vehicle health, ensuring optimal function during critical operations.

By integrating these operational and safety considerations into the design of pumper fire trucks, departments can optimize performance during emergencies. This not only enhances firefighter safety but also reinforces the importance of strategic planning in achieving successful outcomes. The end goal is to deliver an efficient, well-equipped response to emergencies while ensuring the well-being of the firefighters operating within these vital apparatuses.

Image Descriptions

Here are the captions for the images and charts included in the article, enhancing their significance within the context of pumper fire truck design:

-

Pumper Fire Truck in Action

A pumper fire truck in action, responding to an emergency call, showcasing its features surrounded by firefighters and a dynamic firefighting scene. -

Pumper Fire Truck in Action – Alternative

Another perspective of a pumper fire truck responding to an emergency, illustrating its critical role in fire response operations. -

Response Time Chart

This chart illustrates average response times for various pumper truck designs based on their pump capacities and water tank sizes, highlighting the impact of design variables on efficiency.

A visual representation of pumper truck capacities, comparing their efficiencies during emergency scenarios. -

Pump Capacity Specifications in Firefighting

An illustration showcasing pump capacity specifications for firefighting, emphasizing the importance of different pump capacities in effective emergency response operations. -

Modern Fire Truck Designs

This image depicts modern pumper fire truck designs featuring advanced equipment, showcasing enhanced firefighting capabilities in action.