In the realm of firefighting, the design of pumper fire trucks plays a pivotal role in shaping emergency responses. These formidable vehicles are often the first on the scene, tasked with delivering the necessary resources to combat fires effectively and safeguard lives. Therefore, understanding the intricacies of pumper fire truck design is crucial for optimizing their functionality.

Designers must consider a range of effective features and customization options to enhance operational efficiency, responsiveness, and safety. Throughout this article, we will delve into several key aspects of pumper fire truck design, including chassis selection, pump capacity, water tank size, and innovative storage layouts. Each of these elements contributes significantly to the overall performance and effectiveness of fire departments in their critical mission.

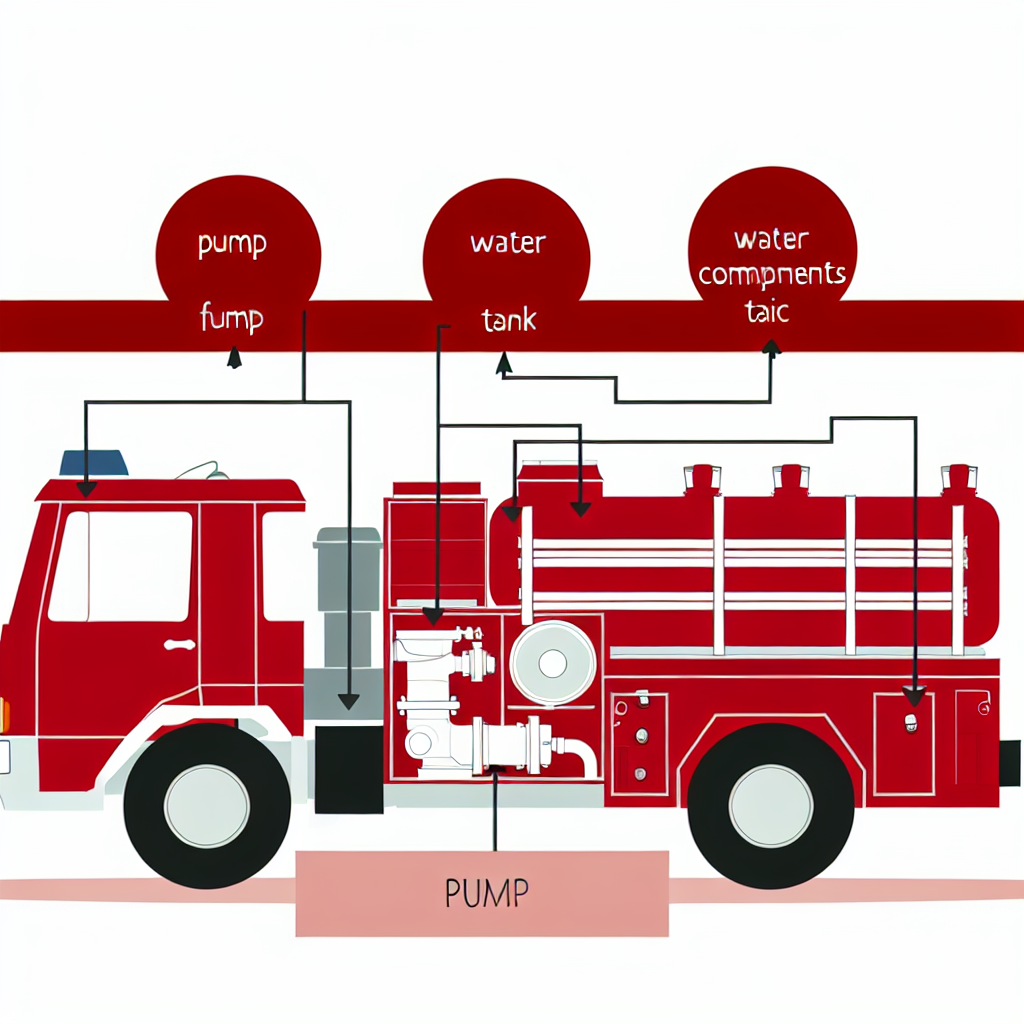

The Significance of Pump Capacity in Pumper Fire Trucks

The pump capacity of pumper fire trucks is a pivotal aspect that directly influences operational efficiency and fire safety during firefighting operations. Typically, pump capacities range between 500 to 3,000 gallons per minute (GPM). This range is crucial as it determines how quickly and effectively firefighters can combat large-scale blazes, thereby impacting their gear’s performance and overall fire response technology utilized.

Having a pump capacity on the higher end of this spectrum allows fire departments to deliver water rapidly, which is essential in situations where fires can spread quickly. For instance, a higher capacity aids in extinguishing fires in large structures or during wildfires, where immediate and sustained water supply is critical. The effectiveness of firefighter gear can also be maximized with adequate pump capacity, ensuring that crews can maintain consistent water flow during emergencies.

On the other hand, lower pump capacities may limit a crew’s ability to deliver sufficient water in a timely manner, especially in larger incidents. South County Fire’s findings illustrate the need for adequate pump capacity, revealing that existing apparatus ran out of water in nearly 30 percent of incidents before establishing a hydrant connection. This statistic underscores the necessity of incorporating fire safety measures that rely on engine performance, thus minimizing the risk of fire spread and loss of property.

Moreover, balancing pump capacity with water tank size presents unique challenges. A standard 750-gallon tank often serves as a compromise between space, weight, sustained water flow duration, and the fire response technology on the truck. This balance is integral for operational efficiency, enabling fire trucks to be agile while still capable of delivering necessary resources.

Ultimately, understanding the significance of pump capacity in pumper fire trucks is vital for fire departments aiming to optimize their response strategies and enhance firefighter safety. The integrated approach focusing on optimal pump capacity not only aids in effective firefighting but also protects the lives of our firefighters during emergencies.

| Truck Model | Pump Capacity (GPM) | Advantages | Limitations |

|---|---|---|---|

| Pierce Velocity | 1,500 | High flow rate, compact design for urban areas | May require frequent refills in rural settings |

| Rosenbauer Panther | 2,000 | Off-road capability, versatile in different terrains | Heavier, may affect maneuverability in tight spaces |

| E-One Typhoon | 1,750 | Excellent support for foam systems | Limited internal space for equipment storage |

| Oshkosh Striker | 3,000 | Best for large-scale fires, very powerful pump | Higher maintenance costs due to complexity |

| Spartan Classic | 1,000 | Budget-friendly, good for small to mid-size fires | Lower flow rate for large incidents |

The Importance of Water Tank Size in Pumper Fire Truck Design

Water tank size is a critical consideration in the design of pumper fire trucks, as it impacts various factors essential for effective firefighting operations. A standard capacity of 750 gallons is often deemed ideal, striking an important balance between weight, space, and duration of operations. This balance allows fire departments to enhance their overall operational performance while accommodating the diverse needs of various firefighting scenarios.

First and foremost, the water tank’s size impacts the weight distribution of the fire truck. A heavier vehicle can lead to greater challenges in maneuverability and speed, particularly when navigating urban environments. By optimizing the tank size, fire truck designers can ensure that the vehicle maintains a manageable weight, allowing it to respond quickly to emergencies. The 750-gallon standard eases weight concerns while still providing a practical amount of water crucial during initial firefighting efforts.

Moreover, space optimization is essential in pumper fire truck design to allow for other critical components like pumps, hoses, and equipment storage. A larger tank could impede available space for these crucial elements, potentially compromising the truck’s operational capabilities. The 750-gallon tank optimally fits within the constraints of standard fire truck frames, ensuring that fire departments can configure their vehicles efficiently without sacrificing functionality.

Additionally, the duration of sustained water flow is of paramount importance during firefighting efforts. The standard 750-gallon tank allows firefighters to deliver a consistent water supply for an extended period without overburdening the vehicle. In fact, findings from South County Fire reveal that existing apparatus frequently ran out of water in nearly 30 percent of incidents before establishing a hydrant connection. This statistic illustrates the importance of having an adequately sized tank that balances initial water supply with operational needs until external resources can be tapped into.

In conclusion, the importance of water tank size in pumper fire truck design cannot be overstated. A 750-gallon tank serves as a versatile benchmark that balances weight, space, and sustained water flow. By carefully considering these factors during the design process, fire departments can ensure that their apparatus is not just efficient but also effective in responding to emergencies, ultimately saving lives and property.

Chassis Selection for Pumper Fire Trucks

Selecting the right chassis is vital to the overall design, functionality, and performance of pumper fire trucks. Key considerations include:

- Weight Distribution: A well-designed chassis ensures even weight distribution, crucial for maneuverability in urban settings and enhancing vehicle stability.

- Maneuverability: The chassis type influences agility and handling, with designs that offer tight turning radii allowing for swift responses during emergencies.

- Safety Features: Adherence to safety standards is paramount. Essential components include:

- Braking Systems: Trucks with a Gross Vehicle Weight Rating (GVWR) over 36,000 pounds must have secondary braking devices, enhancing stopping power and control.

- Electronic Stability Control (ESC): This feature applies selective braking to prevent rollovers and enhance control.

- Roll Stability Control: Activates during sharp turns to decrease rollover risk.

- Cab Integrity Standards: Ensure that cabs can withstand impacts, protecting firefighters.

- Type of Terrain: The chassis must be suitable for both urban and rural applications, with some designs better suited for off-road capabilities.

- Compatibility with Firefighting Equipment: The chosen chassis should accommodate essential firefighting tools, ensuring efficient storage and accessibility for operational effectiveness.

- Regulatory Standards: Compliance with safety regulations like NFPA 1901 is crucial, alongside annual weigh certification to avoid overload incidents.

In summary, chassis selection encompasses many vital factors beyond aesthetics or cost, focusing on safety, performance, and operational efficiency. Fire departments must consider all these aspects to ensure their apparatus meets emergency service demands effectively.

Key Safety Features of Pumper Fire Trucks

Pumper fire trucks are designed with several key safety features to enhance firefighter safety and operational efficiency. Notable design aspects include:

- Low Hose Beds: Positioning hose beds lower on the apparatus allows firefighters to deploy and reload hoses without climbing onto the vehicle, reducing the risk of falls and injuries. A low hose bed height, typically under 60 inches, facilitates quicker hose deployment and minimizes zero-impact time.

- Low-Mounted Ladders: Storing ladders at accessible heights enables firefighters to retrieve and deploy them without using additional equipment or climbing, enhancing safety and efficiency. For instance, curbside ladder storage allows ladders to be removed at approximately five feet from the ground, accommodating various operational scenarios.

- Top-Mounted Pump Panels: Elevated pump panels provide operators with a clear view of the fireground while keeping them away from traffic and other hazards. This design improves safety and operational control.

- Enclosed Ladder Storage: Integrating ladder storage within the body of the apparatus protects equipment from environmental damage and reduces the vehicle’s overall height, enhancing stability and maneuverability. This design also keeps ladders readily accessible without compromising safety.

- Ergonomic Equipment Access: Designing compartments and storage areas at accessible heights reduces the need for firefighters to lift heavy equipment above shoulder level, decreasing the risk of musculoskeletal injuries. Features like slide-out trays and adjustable shelves contribute to safer and more efficient equipment retrieval.

These design elements collectively contribute to a safer working environment for firefighters, enabling them to perform their duties more effectively while minimizing the risk of injury.

In conclusion, effective pumper fire truck design and customization strategies are paramount for enhancing emergency response capabilities. With the critical role that these vehicles play in saving lives and protecting property, it is essential for fire departments to invest time and resources into optimizing their pumper fire truck configurations.

By considering key factors such as pump capacity, water tank size, chassis selection, and safety features, departments can ensure their apparatus meets the unique demands of their operational environments. Prioritizing these design considerations not only improves the efficiency of firefighting efforts but also significantly enhances the safety of our firefighters.

As the challenges of modern emergencies evolve, so too must our approach to pumper fire truck design, making it relevant now more than ever. Fire departments are encouraged to adopt a proactive stance in assessing their current apparatus and exploring innovative customization options for improved emergency response outcomes.

Outbound Links to Credible Sources

To provide additional resources and enhance the authority of our article on pumper fire trucks, we have included outbound links to credible sources regarding fire truck standards and safety features. These articles cover comprehensive guidelines, regulations, and innovations in the field, ensuring that readers can explore further into the standards governing fire apparatus and safety enhancements in firefighting.

- NFPA 1900: Comprehensive Standard for Emergency Response Vehicles: This article discusses the extensive guidelines set forth by the NFPA for fire apparatus design, construction, and maintenance, focusing on safety features and equipment standards.

- State-Specific Regulations on Fire Truck Safety: Learn about specific regulations implemented by various states concerning personnel restraints and equipment storage on fire trucks.

- Daily Checks and Maintenance Protocols: This source highlights the importance of daily inspections and operator training for ensuring fire truck safety and performance.

- Safety Innovations in Fire Trucks: Discover the latest safety technological advancements in fire apparatus, including crash sensor systems and collision avoidance technologies that greatly enhance the safe operation of fire trucks.

- Structural Safety Enhancements in Fire Apparatus: This article discusses how innovations like powered storage devices and corrosion protection contribute to the overall safety and longevity of fire trucks.