In the high-stakes world of emergency response, reliable equipment is crucial. Standardizing heavy-duty rescue apparatus ensures rescue teams respond swiftly during critical moments. Uniform mechanical components improve safety and operational efficiency, enabling crews to focus on saving lives rather than troubleshooting. This article explores the benefits of implementing standardized rescue apparatus in emergency operations, highlighting real-world examples that showcase its significance in enhancing response capabilities.

In 2024, Rescue Squad No.820 achieved remarkable operational success, generating over 1,800 responses. This significant number of responses highlights the squad’s effectiveness in addressing emergency situations.

The implementation of standardized equipment across the department has played a crucial role in this success. By utilizing uniformity in mechanical components, the rescue squad has minimized downtime and streamlined operations during vital moments. The standardization not only enhances response times but also ensures crew familiarity with the equipment, leading to increased confidence and greater efficiency during rescues.

Such statistics underscore the importance of adopting standardized practices in heavy-duty rescue operations, ultimately improving outcomes for the communities served.

Benefits of Standardization in Heavy-Duty Rescue Operations

Standardization in heavy-duty rescue operations is not merely a trend; it represents a strategic shift towards improving the overall effectiveness and safety of emergency response teams. Through the implementation of standardization, organizations can experience several critical benefits.

Enhanced Safety

Safety is paramount in rescue operations where split-second decisions are often required. Standardization of mechanical components leads to greater mechanical consistency, enabling rescue teams to rely on familiar equipment under pressure. When personnel are accustomed to specific tools and vehicles, the likelihood of errors decreases significantly, which can make a crucial difference in high-stress situations.

Improved Efficiency

Efficiency is greatly enhanced through equipment uniformity. When responders are trained on the same equipment across various units, it reduces the learning curve associated with new or unfamiliar machinery. This understanding allows for faster deployment and execution of rescue strategies, ultimately saving valuable time during emergencies.

Maintenance Consistency

Maintenance practices are also streamlined due to standardization. With similar equipment, maintenance protocols can be standardized, ensuring that all units are cared for uniformly, resulting in fewer mechanical failures during critical operations. This predictability contributes to overall cost savings as well, by reducing the need for diverse spare parts and specialized training for equipment maintenance.

In conclusion, the standardization of heavy-duty rescue apparatus fosters an environment where safety, efficiency, and reliability are prioritized, ultimately leading to more successful rescue operations.

Practical Perspectives on Standardization in Heavy-Duty Rescue Operations

Richard Riley, Fire Apparatus Manager at Prince George’s County Fire/EMS Department, offers critical insights into the practical approaches to standardization within heavy-duty rescue operations. He believes that evaluating manufacturers’ capabilities before starting the design process is essential for operational success. He states, “Start by evaluating manufacturers’ capabilities and past projects, then involve both engineers and frontline firefighters early in the specification process. Working with Pierce Manufacturing meant we were able to tailor our apparatus to match equipment needs, safety goals, and real-world response demands.”

This perspective emphasizes not only the importance of working collaboratively with manufacturers but also the necessity of bridging the gap between engineering and practical firefighting. By tailoring apparatus to meet specific requirements, fire departments can ensure that their equipment is not only effective but also intuitive for crews during emergency responses.

Additionally, Riley acknowledges the enduring advantages of established designs in enhancing operational effectiveness. He mentions, “The traditional walk-in compartment design has proven its effectiveness over decades of rescue operations. For our department, protecting critical equipment combined with the ability to carry more crew made it the right choice.”

Riley’s views underscore that embracing standardization is vital for fostering safe, efficient, and reliable rescue operations in an environment where every second counts. Furthermore, the importance of having standardized emergency response equipment cannot be overstated, as it significantly contributes to successful outcomes in high-pressure situations.

| Manufacturer | Capabilities | Key Features | Notable Projects | Innovation |

|---|---|---|---|---|

| Pierce Manufacturing | Specializes in custom fire and rescue apparatus, heavy-duty vehicles | Walk-in rescues, non-walk-in rescues, robust chassis, integrated breathing air setups | Delivered Quantum quint 105-foot aerial ladders to Oshkosh Fire Department (2016); contracts with Providence Fire (2020); 21 fire apparatus order to Huntsville Fire (2021) | Introduction of TAK-4 independent front suspension and TAK-4 T3 steering for enhanced maneuverability |

| Oshkosh Corporation | Leading manufacturer of specialty vehicles, including fire apparatus | Specialty vehicle design expertise, robust construction for various operational needs | Various contracts including municipal fire departments for aerials and pumpers, continuous updates to their apparatus line | Development of advanced control systems for improved vehicle management and response times |

Operational Excellence in Emergency Services with Heavy-Duty Rescue Trucks

Heavy-duty rescue trucks are integral to operational excellence in emergency services, offering advanced features that enhance safety, efficiency, and effectiveness during critical operations. Recent advancements in vehicle stabilization and scene lighting systems have significantly contributed to these improvements.

Vehicle Stabilization Systems

Effective stabilization is crucial for ensuring the safety of both responders and victims during rescue operations. Modern rescue trucks are equipped with advanced stabilization capabilities, such as front-mounted winch systems and hydraulic stabilization devices. For instance, the Prince George’s County Fire/EMS Department’s Rescue Squad No. 820 features a front-mounted 15,000-pound winch system, which aids in vehicle recovery and provides critical stabilization during complex extrications, preventing unwanted vehicle movement and enhancing crew safety.

Scene Lighting Systems

Advanced scene lighting is vital for ensuring visibility and safety during nighttime or low-visibility operations. Modern emergency vehicles are equipped with both 12-volt system scene lights and generator-powered lighting. The 12-volt system provides immediate illumination upon arrival, while generator-powered lights support extended operations requiring sustained lighting. This dual-system approach aligns with the philosophy of “turning night into day,” ensuring superior visibility during emergency responses.

Additionally, the integration of “smart” lighting systems that adjust intensity and patterns based on the situation can enhance safety. Elevating scene lights can reduce glare and improve illumination of topographical features, aiding responders in navigating complex terrains. For example, light towers that can rotate up to 360 degrees allow for optimal positioning, directing light precisely where needed and minimizing blinding effects on both responders and motorists.

These advancements in vehicle stabilization and scene lighting systems are pivotal in enhancing the operational capabilities of heavy-duty rescue trucks, ensuring that emergency services can respond effectively and safely to a wide range of incidents.

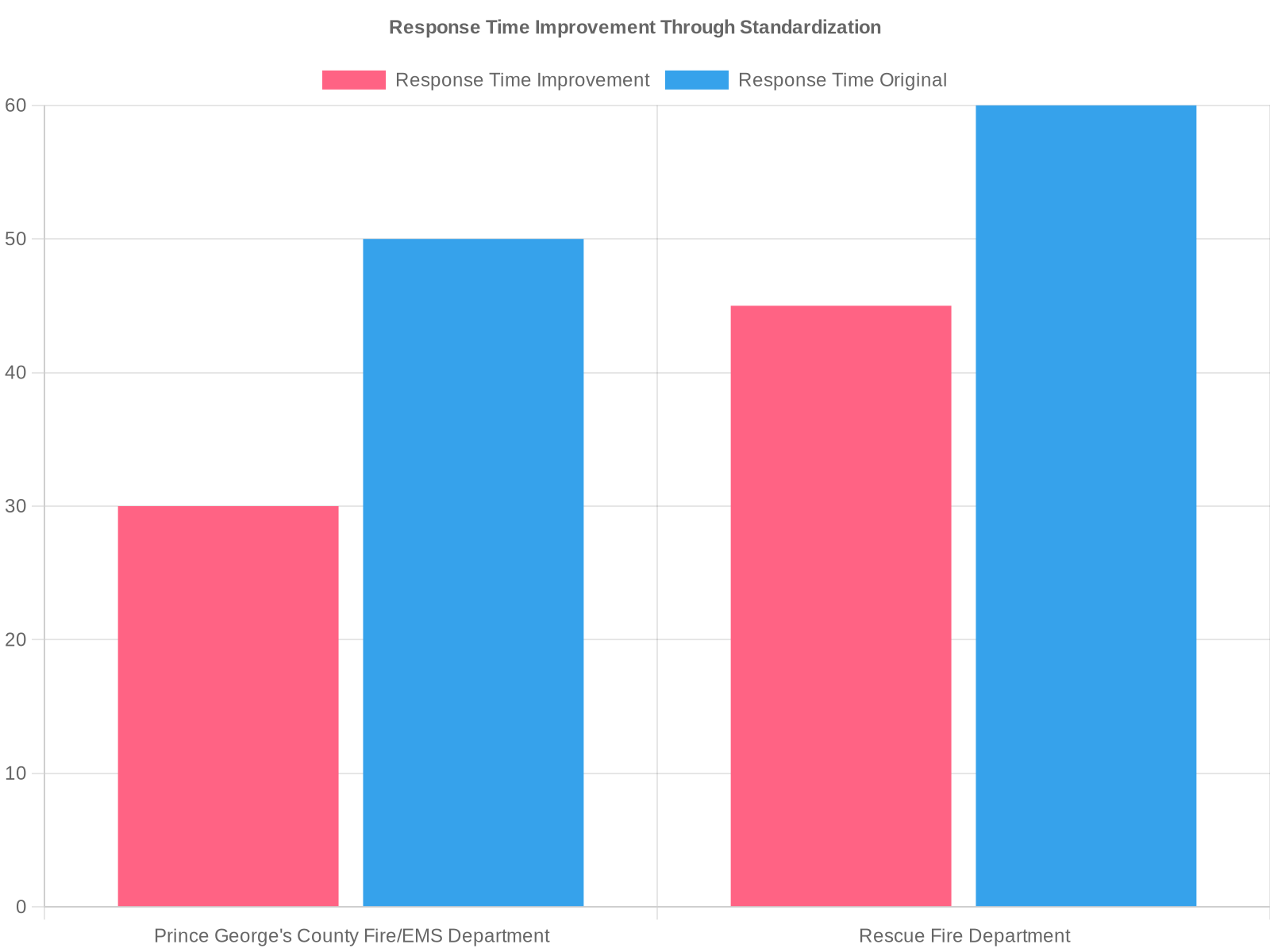

User adoption of standardized heavy-duty rescue apparatus has proven effective in enhancing operational efficiency, safety, and cost savings across various fire departments. The Prince George’s County Fire/EMS Department in Maryland serves as a prime case study. By implementing a strategy focused on standardization with Pierce Manufacturing, the department achieved significant improvements in operational response. This approach resulted in reduced diagnostic and repair times, as mechanics became adept at working with familiar systems. Moreover, standardized equipment layouts allowed rescue crews to quickly locate and operate essential tools, enhancing responsiveness in emergencies. In 2024, for instance, Rescue Squad No. 820 responded to over 1,800 emergencies, underscoring the benefits of this standardization strategy. Financially, the department reported lower maintenance costs due to streamlined parts procurement processes, illustrating how standardization can contribute to overall budget efficiency.

Similarly, the Norfolk Fire Department’s evaluation of new fire apparatus design changes revealed that standardized features increased operational performance, quality, and customer support. Although specific downtime statistics were not provided, the feedback indicated that four out of five departments expressed high satisfaction with their standardized fire apparatus, further supporting the notion that standardization leads to improved effectiveness in emergency response operations.

These case studies collectively highlight the positive impact of adopting standardized heavy-duty rescue apparatus, showcasing enhanced operational readiness, safety, and cost-effectiveness for fire departments committed to optimizing their rescue operations.

In conclusion, the standardization of heavy-duty rescue apparatus is not just a best practice but a vital component in enhancing the efficiency and safety of emergency response operations. Through real-world applications, such as those demonstrated by the Prince George’s County Fire/EMS Department, we see how standardization leads to increased familiarity with equipment, reduced downtime, and improved response times, all of which are critical in life-saving situations.

As emergency departments reflect on the insights shared in this article, it is essential to recognize the transformative potential of standardization. By embracing uniformity in mechanical components and adopting standardized practices, departments can bolster operational excellence and ensure their teams are better equipped to handle emergencies effectively.

Encourage your organization to evaluate standardization efforts that can enhance your operational capabilities and ultimately save lives.

Expanded Benefits of Standardization in Heavy-Duty Rescue Operations

Standardization in heavy-duty rescue operations is instrumental in transforming how rescue teams respond to emergencies. This strategic approach yields a multitude of benefits that extend beyond the surface level, affecting every aspect of operational effectiveness.

Enhanced Safety

Safety is the cornerstone of effective emergency response. With standardized mechanical components, organizations can foster familiarity among their personnel. Firefighters trained to operate standardized equipment are less likely to experience confusion during emergencies. As a result, the risk of accidents decreases, enabling teams to focus entirely on executing life-saving interventions.

A striking example is the implementation at the Prince George’s County Fire/EMS Department. By standardizing their rescue equipment, they not only improved operational safety but also significantly increased their response efficiency, as reflected in their over 1,800 responses in 2024. This high response volume illustrates how effective standardization can lead to higher performance metrics in emergency situations.

Improved Efficiency

Uniformity in equipment streamlines training protocols, enabling newer personnel to integrate more swiftly into their roles. A well-known case study from the Norfolk Fire Department demonstrated that departments utilizing standardized fire apparatus experienced greater operational performance, leading to an operational cost savings model. With similar equipment, emergency responders can react more independently and dynamically, enhancing on-the-ground efficiency.

Maintenance Consistency

The standardization of equipment simplifies maintenance procedures. All units can follow uniform maintenance schedules and protocols. For example, the USDA Forest Service reported that through the standardization of firefighting gear and equipment, certain agencies saw an average savings of 25 percent in procurement costs. Maintaining similar equipment reduces the time and complexity associated with repairs, ensuring that vehicles are always ready for immediate deployment during emergencies.

In a world where every second counts, adopting a standardized approach to maintenance can lead to improved reliability of rescue equipment.

Cost Savings

By consolidating purchases and reducing the variety of spare parts needed, fire departments can experience substantial financial savings. This approach allows departments to allocate resources more efficiently and invest in further training or additional equipment that may enhance their operational capabilities. Standardized systems not only yield direct cost reductions but also facilitate better tracking of expenses and budgeting, which is crucial in public service sectors with limited funding.

With case studies showcasing that standardized systems lead to improved customer support and satisfaction rates, it becomes evident that standardization is not merely a strategy but a pathway to more proficient emergency service management.

Conclusion of Benefits

In summation, the multifaceted benefits of standardization in emergency response illustrate the strategic importance of this approach. Enhanced safety, improved efficiency, streamlined maintenance protocols, and significant cost savings converge to create a highly effective operational environment. Emergency services are thus encouraged to embrace standardization not merely as a best practice but as a fundamental principle guiding their operations.

Operational Excellence in Emergency Services with Heavy-Duty Rescue Trucks

Heavy-duty rescue trucks have evolved significantly, integrating advanced technology to ensure operational excellence during emergencies. These innovations enhance safety, efficiency, and overall effectiveness, contributing to the successful execution of rescue missions.

Vehicle Stabilization Systems

Modern rescue trucks come equipped with superior stabilization systems. An instance of this technology is the Oshkosh TAK-4 Independent Suspension System, which significantly improves off-road vehicle handling. For emergency responders, the importance of vehicle stability cannot be overstated, particularly in challenging terrains where precise maneuvering can mean the difference between a successful rescue and a tragic failure.

In the context of operational excellence, the Prince George’s County Fire/EMS Department’s Rescue Squad No. 820 stands out. Equipped with a front-mounted 15,000-pound winch, this truck is designed for optimal stabilization during complex rescue operations. Such features make operations safer for both responders and the victims they aim to assist, ultimately improving service delivery.

Scene Lighting Systems

Visibility is critical during emergency operations, especially at night. Heavy-duty rescue trucks now feature advanced scene lighting systems that allow teams to illuminate their surroundings effectively. High-intensity LED light towers and mirrored floodlights are standard, providing reliable and consistent lighting conditions regardless of time or weather. This essential capability allows rescue teams to assess situations more quickly and ensure that operations proceed safely.

Moreover, cloud-enabled solutions such as Whelen’s Traffic Preemption technology ensure that emergency vehicles can have streamlined access through intersections, improving operational response times. This integration of technology significantly enhances situational awareness and reaction times during crucial moments.

Additional Technological Innovations

- Infrared Vision Systems: The use of infrared cameras enables rescue teams to observe thermal imprints of subjects, proving essential in low-visibility environments such as smoke-filled homes. Such technology brings a new layer of assurance during rescues.

- Autonomous Systems: Unmanned ground vehicles equipped with AI capabilities support first responders by providing real-time data during missions, enhancing safety and efficacy in risk-prone environments.

Conclusion of Operational Excellence

These technological advancements demonstrate how heavily laden trucks have transitioned from conventional vehicles to multifaceted tools that significantly enhance emergency responses. As we analyze the various components of operational excellence, it becomes evident that investing in these technologies results in safer, more efficient, and ultimately more successful emergency response operations.

Vehicle Stabilization Systems

Effective stabilization is essential for the safety of responders and victims during rescue operations. Modern rescue trucks come equipped with advanced stabilization features. These include front-mounted winch systems and hydraulic stabilization devices.

For example, the Rescue Squad No. 820 in Prince George’s County has a front-mounted winch that can lift up to 15,000 pounds. This winch aids in vehicle recovery. It also helps provide critical stabilization during complex extrications. This capability is necessary to prevent unwanted vehicle movement, enhancing crew safety during rescues.

By ensuring vehicle stabilization, emergency responders can focus on their tasks without worrying about their trucks moving unexpectedly. This technology is crucial for maintaining safety and improving the overall effectiveness of rescue operations. It allows teams to work more confidently in high-pressure situations, directly contributing to better outcomes during emergencies.