In the high-stakes world of firefighting, every second counts and the right equipment can mean the difference between disaster and success. This is especially true when it comes to pumper fire truck design, an area where balancing operational efficiency and firefighter safety is paramount.

As the first responders to emergencies, fire departments rely on these specialized vehicles to deliver rapid and effective assistance. However, optimizing pumping and storage systems within these trucks is not just a matter of capability; it is also about ensuring that firefighters can perform their duties without unnecessary risk.

By thoughtfully considering the design elements—ranging from pump capacity to water tank size—departments can enhance their operational readiness and adapt to the evolving needs of the communities they serve. This article delves into the critical aspects of pumper fire truck design, focusing on strategies that improve both performance and safety on the front lines.

Importance of Pump Capacity in Pumper Fire Truck Design

In the field of firefighting, pump capacity is a critical factor that directly influences the effectiveness of emergency responses. Understanding how pump capacity impacts operations can be the key to saving lives and property.

How Pump Capacity Affects Operational Efficiency

- Rapid Response: Pumper ratings can range from 500 to 3000 gallons per minute (GPM). A higher capacity enables quicker water delivery to the fire scene, allowing firefighters to start suppression efforts without delay.

- Extended Operations: Departments must consider tank size alongside pump capacity. A standard 750-gallon tank is often utilized, striking a balance between weight and duration of flow. This ensures that firefighters have enough water during critical moments before connecting to a hydrant.

- Avoiding Shortages: Research reveals significant issues related to inadequate pump capacity. For instance, South County Fire reported that their apparatus ran out of water in nearly 30% of incidents before establishing a hydrant connection, highlighting the risks associated with insufficient pump ratings.

Statistics That Illustrate the Need

To illustrate the importance of pump capacity:

- In emergency scenarios, low-capacity pumps (under 1000 GPM) may struggle to manage larger structural fires, prolonging the response time and potentially worsening the fire’s impact.

- Conversely, high-capacity pumps (2000 GPM and above) can significantly enhance firefighting capabilities, allowing for simultaneous water delivery to multiple hose lines or apparatus.

Conclusion

Choosing the appropriate pump capacity is not merely a technical detail; it is a life-saving decision. Departments must assess their specific operational needs to ensure their pumper fire trucks are equipped to handle emergencies efficiently. By investing in the right pump capacities, fire departments can enhance not only their operational readiness but also ensure the safety and efficiency of their firefighting teams.

User Adoption Trends in Pumper Fire Truck Models: Fire Department Technology Trends

The fire truck industry’s user adoption trends show a significant shift towards advanced pumping systems and innovative storage solutions to enhance efficiency. Here are the key findings:

- Adoption of Advanced Pumping Systems: Recent reports indicate that 78% of new pumper truck purchases incorporate advanced pumping systems featuring flow monitoring technology. This integration not only aids in real-time performance assessment but also facilitates better resource management in emergency situations.

- Enhanced Storage Systems: Fire departments are focusing on maximizing storage space, with innovations that offer 15-20% more compartment capacity through redesigned layouts. Many apparatus now feature slide-out trays, which improve access to equipment and can be critical during emergencies.

- Focus on Corrosion Resistance: A noteworthy trend is the prioritization of tanks constructed with corrosion-resistant coatings, which are expected to extend service life by up to 40% compared to traditional tank materials. With 62% of departments opting for these enhanced tanks, the longevity and reliability of the pumper trucks are significantly improved.

- High-Efficiency Pumps: The adoption of high-efficiency pumps has surged by 35%, with these systems capable of reducing fuel consumption by as much as 22%. This not only lowers operational costs but also contributes to environmental sustainability in firefighting operations.

- Smart Monitoring and Quick Access: Smart tank monitoring systems have been embraced by 45% of new apparatus, facilitating an 18% reduction in water waste. Moreover, the introduction of quick-access compartments in storage systems has improved deployment times by 30%, which is crucial during time-critical incidents.

- Technical Innovations: Modern pumping systems equipped with automatic pressure regulation have resulted in a 40% decrease in pump-related incidents. Additionally, 58% of new pumper trucks now come with customizable compartment systems, allowing departments to tailor storage solutions to their specific needs.

These trends reflect a larger movement towards improving operational efficiency, safety, and resource management in pumper fire truck design.

Storage Systems for Equipment in Pumper Fire Trucks

Effective storage systems are crucial for pumper fire trucks as they ensure that firefighters can access essential equipment quickly and efficiently during emergencies. The right storage solutions not only improve serviceability but also enhance safety by minimizing the time spent retrieving gear. Here’s an overview of key components and innovations in storage systems for pumper fire trucks:

Types of Compartmental Solutions

- Standard Compartments: Traditional compartments are designed to hold essential firefighting equipment such as hoses, nozzles, and personal protective gear. These compartments are typically organized with dividers and labels for easy identification.

- Roll-Out Trays: These trays allow quick access to equipment stored at the back of the truck, minimizing bending and lifting, which can be challenging during emergencies.

- Slide-Out Shelving Systems: This innovation provides firefighters with a clear view of their equipment and ensures they can pull out multiple items without cluttering the aisle.

- Vertical Storage Solutions: Utilizing previously wasted vertical space, these designs optimize storage by allowing firefighters to access tools without obstructing other compartments.

Enhanced Serviceability and Accessibility

- Customizable Layouts: Many modern pumper fire trucks come with modular compartment designs that can be adjusted based on the department’s needs, ensuring that every piece of equipment has an optimal storage space.

- Integrated Features: Advanced storage systems now include features such as LED lighting for visibility, weather-sealed compartments to protect equipment from elements, and integrated charging stations for electronic gear.

- Ergonomic Design: Compartment doors equipped with gas struts facilitate easy opening, even in high-pressure situations, while ergonomic handles improve access.

Innovative Storage Solutions

- Smart Storage Systems: Brands like HME and Rosenbauer have pioneered systems incorporating RFID tracking to help keep inventory organized and readily accessible. These smart systems can also include power management systems to maintain and charge essential equipment.

- Quick-Access Compartments: Innovations such as these allow for rapid retrieval of critical medical equipment and hazmat gear, with intuitive layouts to facilitate swift action.

Conclusion

Investing in comprehensive storage systems on pumper fire trucks is vital for enhancing operational efficiency and firefighter safety. By incorporating innovative compartment solutions and thoughtful design, fire departments can ensure that their responders are equipped for rapid and effective action when every second counts. Efficient equipment storage not only streamlines operations but also significantly contributes to saving lives.

| Model | Manufacturer | Pump Capacity (GPM) | Tank Size (Gallons) | Unique Features |

|---|---|---|---|---|

| Arrow XT | Pierce Manufacturing | 1,250 – 2,000 | 500 – 1,000 | Husky™ 3 foam systems, customizable configurations |

| Enforcer | Pierce Manufacturing | 1,500 – 2,000 | 500 – 1,000 | Advanced water flow management technology |

| Velocity | Pierce Manufacturing | 1,500 – 2,000 | 600 – 1,000 | Multiple compartment layouts, enhanced safety features |

| Striker | Oshkosh Corporation | 1,500 – 2,000 | 500 – 1,000 | Oshkosh TAK-4® independent suspension, Command Zone™ electronics |

| Oshkosh Commercial Pumper | Oshkosh Corporation | 1,000 – 2,000 | 500 – 1,250 | Foam capability, durable and serviceable design |

| Striker ARFF | Oshkosh Corporation | Up to 4,500 | Large foam tank sizes | High-performance pumping, advanced all-terrain capabilities |

Impact of Water Tank Size on Firefighting Effectiveness

In firefighting, the size of the water tank on pumper fire trucks plays a crucial role in determining the effectiveness and efficiency of operations. A commonly adopted standard is a 750-gallon water tank, which strikes a balance among space, weight, and the duration of sustained water flow. Here we explore the implications of tank size in different firefighting contexts.

750-Gallon Standard Tank

- Balance of Factors: The 750-gallon tank is favored because it offers adequate water supply for initial fire attack while ensuring that the truck remains manageable in terms of weight and size.

- Sufficient Flow: With this amount of water, firefighters typically have around 2 to 3 minutes of continuous flow, which is often sufficient for the initial suppression efforts in many scenarios before connecting to a hydrant.

Trade-offs

- Weight Considerations: Larger tanks, while providing more water, add significant weight. For instance, water weighs approximately 8.3 pounds per gallon, meaning a larger tank can impact the truck’s acceleration, braking, and overall fuel efficiency.

- Maneuverability: Smaller tanks allow fire trucks to navigate urban areas with narrow streets more easily, making them ideal for departments that primarily operate in densely populated regions.

- Operational Constraints: In rural areas, where fire departments might face longer distances to water sources, larger tanks (up to 1,000-2,000 gallons) are often necessary to sustain longer operations while minimizing the need for water shuttles.

Unique Needs of Different Departments

- Urban Departments: Often utilize 500-750 gallon tanks due to the convenience of hydrant access, allowing for quicker replenishment. The priority here is agility and the ability to maneuver in tight spaces.

- Rural Departments: Tend to require more robust systems with tanks exceeding 1,000 gallons due to fewer water sources and increased response times. This configuration ensures that they can effectively combat large-scale fires without relying heavily on external water supplies.

Conclusion

Ultimately, the choice of tank size hinges on the specific needs and operational capabilities of each fire department. While a 750-gallon tank offers a practical standard for suburban departments dealing with moderate challenges, customization based on local fire dynamics represents an essential consideration in pumper fire truck design.

The Importance of Foam Systems in Pumper Fire Truck Design

Foam systems have become an essential component of pumper fire truck design, significantly enhancing firefighting effectiveness. According to James Curtis, a well-respected industry expert, “foam systems are no longer optional equipment for modern pumpers – they’re essential for effective flammable liquid fire suppression.” The integration of these systems allows firefighters to swiftly switch from water to foam application, creating a vapor-suppressing layer that prevents the reignition of fires. In his perspective, Curtis emphasizes that “the ability to rapidly deploy foam can mean the difference between containing a fuel fire and having it escalate into a major incident.”

Modern foam systems are equipped with automated proportioning technology that ensures precise foam-to-water ratios, critical for combating various types of flammable liquids. Curtis elaborates that “today’s systems provide consistent foam quality regardless of flow rate,” which enhances the safety and efficiency of firefighting operations. This capability enables firefighters to engage from greater distances and respond promptly to hazardous incidents involving fuels and chemicals. Furthermore, the National Fire Protection Association (NFPA) standards mandate minimum foam capacities and flow rates for pumper fire apparatus, ensuring that these essential features are incorporated into truck designs to meet the challenges of modern firefighting. In summary, foam systems significantly contribute to the operational effectiveness and safety of firefighting efforts, making them an indispensable aspect of pumper fire truck design.

Conclusion

In conclusion, the optimization of pumping and storage systems in pumper fire trucks is vital for enhancing both operational efficiency and firefighter safety. Understanding the significance of pump capacity, water tank size, and innovative storage solutions allows fire departments to ensure their apparatus meet the demands of modern firefighting. The right pump capacity enhances rapid response times, while effective water tank sizes provide adequate flow during critical moments. Moreover, advanced storage systems facilitate swift access to essential equipment, minimizing delays during emergencies.

Fire departments must take these factors into account when evaluating their fire apparatus. By investing in thoughtfully designed pumper fire trucks that balance performance and safety, departments can equip their firefighters to react promptly and effectively in challenging situations. As each community has unique needs, customizing apparatus based on specific operational contexts will ultimately support better emergency management and save lives during critical incidents.

Transitioning to User Adoption Trends

The emphasis on pump capacity in pumper fire truck design directly correlates with the evolving user adoption trends in the industry. As fire departments recognize the critical role that pump performance plays in emergency response effectiveness, their purchasing decisions reflect a growing preference for advanced technologies that enhance not just pumping capabilities but overall operational efficiency.

The integration of high-capacity pumps allows firefighters to manage larger incidents more effectively, while departments invest in trucks equipped with innovations such as flow monitoring and intelligent storage solutions. This trend is indicative of a broader movement within the fire service, where prioritizing safety and efficiency in firefighting operations drives both the design and usage of new apparatus. With these advancements, fire departments can ensure that they are not only meeting current demands but are also prepared for future challenges in emergency responses.

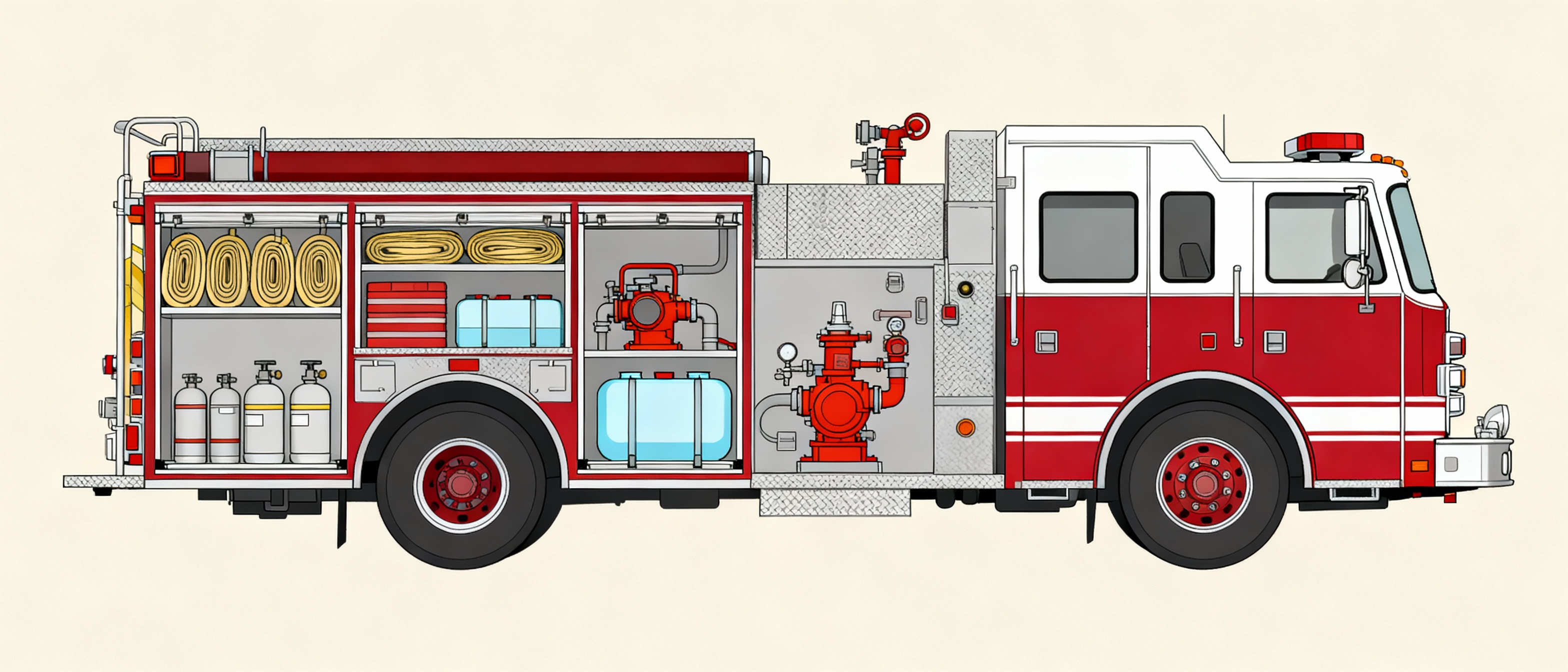

Reviewing the visuals in the article, it appears that the comparison table includes essential specifications about various pumper fire truck models. It should ensure uniqueness in design to prevent redundancy with visuals like the layout image showing storage solutions. The content headings suggest that innovative storage systems have been emphasized, requiring distinct visuals that complement their descriptions. Also, the layout image serves a different purpose than the comparison table and should retain its relevance.

The article includes a good variety of visuals, such as a layout image and a comparison table detailing pumper fire trucks. Each visual serves its unique purpose. The comparison table presents technical specifications, while the layout image illustrates the physical design. The text also describes specific features and enhancements about pumper fire truck technology, allowing for a comprehensive understanding of the subject matter. As long as the visuals maintain these distinctions and align with the text, they add significant value.