In emergency response, the design of pumper fire trucks is crucial. These specialized vehicles are usually the first to arrive at the scene, so their configuration must facilitate quick action. Operating effectively requires efficiency and the safety of firefighters.

Several key considerations shape the design of pumper fire trucks. These include chassis selection, pump capacity, and water tank size. Furthermore, the layout of onboard storage directly impacts a fire department’s ability to fight fires and protect lives.

In this article, we will explore the intricate aspects of pumper fire truck design. Each feature plays a significant role in the overall effectiveness of these lifesaving vehicles. We will emphasize the need for customized solutions that effectively address the unique challenges firefighters face today.

Pump Ratings and Their Impact on Emergency Responses

Pump ratings for fire trucks typically range from 500 to over 3,000 gallons per minute (GPM), with the majority of standard fire engines configured to deliver between 1,000 and 2,000 GPM. This range is crucial in the context of emergency response, as higher pump capacities enable firefighters to deliver substantial volumes of water, which is essential for efficiently controlling and extinguishing fires.

Types of Fire Trucks Based on Pump Capacity:

- Municipal Fire Engines: Commonly equipped with pumps delivering 1,000 to 2,000 GPM and carrying onboard water tanks ranging from 500 to 1,000 gallons. This design ensures a ready supply of water upon arriving at fire scenes, enhancing operational efficiency.

- Industrial and Airport Crash Trucks: Particularly in high-risk scenarios, these vehicles often exceed pump capacities of 3,000 GPM. For instance, specialized airport crash tenders can deliver up to 3,000 GPM or more, addressing demands for rapid water delivery during large-scale emergencies.

Implications for Emergency Response Effectiveness:

Enhanced pump capacities translate to the ability for fire departments to release greater water volumes, which is particularly vital for combating large or rapidly escalating fires. In contexts such as industrial settings or locations with limited water infrastructure, these capabilities become even more crucial. For example, advancements like the high-capacity “Double Thunder” pump demonstrate the firefighting industry’s commitment to innovation, offering delivery rates of 6,000 GPM for industrial emergencies.

The modern trend is shifting toward higher capacity pumps and larger water tanks. Fire departments increasingly specify 1,500 GPM pumps and larger tanks to enable a more robust initial attack and extended firefighting support, especially in water-scarce regions.

In summary, the choice of pump capacity is a significant factor that directly influences emergency response effectiveness. Larger capacities ensure quicker, more efficient water delivery, essential for fire suppression and firefighter safety.

Pump Ratings and Their Impact on Emergency Responses

Pump ratings for fire trucks typically range from 500 to over 3,000 gallons per minute (GPM), with the majority of standard fire engines configured to deliver between 1,000 and 2,000 GPM. This range is crucial in the context of emergency response, as higher pump capacities enable firefighters to deliver substantial volumes of water, which is essential for efficiently controlling and extinguishing fires. This capability is instrumental for firefighter equipment and fire safety during emergencies.

Types of Fire Trucks Based on Pump Capacity:

- Municipal Fire Engines: Commonly equipped with pumps delivering 1,000 to 2,000 GPM and carrying onboard water tanks ranging from 500 to 1,000 gallons. This design ensures a ready supply of water upon arriving at fire scenes, enhancing operational efficiency and facilitating effective responses in emergency situations.

- Industrial and Airport Crash Trucks: Particularly in high-risk scenarios, these vehicles often exceed pump capacities of 3,000 GPM. For instance, specialized airport crash tenders can deliver up to 3,000 GPM or more, addressing demands for rapid water delivery during large-scale emergencies.

Implications for Emergency Response Effectiveness:

Enhanced pump capacities translate to the ability for fire departments to release greater water volumes, which is particularly vital for combating large or rapidly escalating fires. In contexts such as industrial settings or locations with limited water infrastructure, these capabilities become even more crucial. For example, advancements like the high-capacity “Double Thunder” pump demonstrate the firefighting industry’s commitment to innovation, offering delivery rates of 6,000 GPM for industrial emergencies, enabling emergency response vehicles to act swiftly under pressure.

The modern trend is shifting toward higher capacity pumps and larger water tanks. Fire departments increasingly specify 1,500 GPM pumps and larger tanks to enable a more robust initial attack and extended firefighting support, especially in water-scarce regions. These advancements greatly contribute to improving fire safety and effectiveness during firefighting operations.

In summary, the choice of pump capacity is a significant factor that directly influences emergency response effectiveness. Larger capacities ensure quicker, more efficient water delivery, which is essential for fire suppression and firefighter safety.

Importance of Chassis Selection in Pumper Fire Truck Design

The chassis selection in pumper fire truck design is fundamentally important, acting as the backbone of the vehicle and supporting all critical systems onboard. A well-chosen chassis contributes not only to the structural integrity but also to the overall functionality and operational effectiveness of the fire truck. Here are the key factors that should be considered during chassis selection:

- Weight Capacity: Fire trucks carry substantial loads including pumps, water tanks, hoses, and firefighting equipment. Therefore, selecting a chassis with a high weight capacity is essential to ensure that it can support these heavy loads without compromising safety.

- Durability: Firefighting can be extremely demanding, often involving off-road conditions and inclement weather. A robust chassis made from durable materials will prolong the lifespan of the fire truck and reduce maintenance costs over time.

- Maneuverability: Fire scenes can often be chaotic, requiring fast and efficient maneuvering to position the truck correctly. A chassis designed for optimal handling and turning radius can significantly enhance operational effectiveness in navigating tight spaces and crowded environments.

- Compatibility with Equipment: Different fire departments may have unique equipment requirements. A chassis must be adaptable to accommodate various firefighting tools and technologies. This includes provisions for mounting pumps, hose reels, and other equipment crucial for firefighting missions.

- Height Considerations: The height of the chassis impacts the overall height of the truck, which is crucial for accessibility and operation. Chassis height affects not only the loading and unloading of equipment but also the ability to navigate under low bridges and overpasses.

- Ease of Access: Access to critical components for maintenance is vital for operational readiness. A well-designed chassis allows for easy access to the engine, transmission, and other key systems, facilitating quicker repairs and inspections.

In summary, the right chassis selection has a profound impact on the overall performance and efficiency of a pumper fire truck. It influences not only ability and safety during firefighting operations but also the longevity and maintainability of the truck itself. Consequently, fire departments must carefully evaluate their needs and the characteristics of available chassis options to ensure optimal performance in emergency situations.

| Manufacturer | Model | Pump Capacity (GPM) | Water Tank Size (Gallons) | Key Features |

|---|---|---|---|---|

| Pierce Manufacturing | Arrow XT | 1500 – 2000 | 500 – 1000 | Customizable storage, advanced safety features |

| Oshkosh Corporation | Striker 1500 | 1500 – 3000 | 500 – 1200 | All-wheel drive, low profile for tight spaces |

| E-One | Cyclone II | 1000 – 2000 | 500 – 1000 | Easy access for maintenance, durable build |

| Rosenbauer | Commander 4 | 1000 – 2000 | 750 – 1500 | High visibility, ample storage compartments |

| Ferrara Fire Apparatus | Inferno | 1500 – 2000 | 500 – 1000 | Engineered for maneuverability, customizable options |

This table provides a comparison of key specifications and features of leading pumper fire truck manufacturers, each known for their unique contributions to fire truck design.

The Importance of Water Tank Size in Pumper Fire Truck Design

In the critical realm of firefighting, the importance of water tank size in pumper fire trucks cannot be overstated. Fire departments rely on these vehicles as their front-line defense against fires, making the design choices vital for operational success. A larger water tank is invaluable, as it provides firefighters with the immediate water supplies needed to combat blazes effectively during the initial response phase.

Enhanced Emergency Support

When pumper fire trucks are deployed to an incident, the availability of water is often a determining factor in successful fire suppression. A fire can escalate quickly, making the speed and amount of water available essential. A truck equipped with a larger water tank can carry anywhere from 1,000 to 3,000 gallons of water or more, allowing for longer engagement times before needing to refill from a hydrant or other water source. This capability is particularly critical in rural or underserved areas where hydrants may be scarce or absent.

Moreover, with the ability to tap into vast stores of water, firefighters can initiate aggressive attack strategies that can significantly limit fire spread and ultimately save lives and property. For instance, if a pumper truck runs low on water, it may need to retreat to refill, consequently losing valuable time where every second counts.

Relationship with Pump Capacity

The relationship between water tank size and pump capacity is equally crucial. While pumps are rated to deliver impressive flows—often between 1,000 and 2,000 gallons per minute (GPM)—the size of the tank dictates how long this water can be put to use. A larger tank complements a high-capacity pump effectively, ensuring that firefighters can maintain a steady and robust flow of water during the initial firefighting phases.

For example, if a pumper truck features a 1,500 GPM pump but only carries a 500-gallon tank, it can quickly deplete its resources in just a matter of minutes. Conversely, a larger tank allows for sustained output, enabling firefighters to continue dousing flames without the immediate need to find refills.

Alongside pump ratings, water tank size also influences how fire departments prepare for various scenarios and emergencies, ensuring that they are equipped to deal with the unpredictability of fire situations. Firefighters are better positioned to respond to larger fires or multiple incidents when they have the water resources available to tackle the risks head-on.

In conclusion, the water tank size in pumper fire trucks is a critical component of effective firefighting design. It enables quick responses, supports extensive fire suppression efforts, and contributes significantly to the safety and efficiency of firefighting operations. Thus, careful consideration of tank size is paramount in designing apparatuses that meet the rigorous demands of fire emergencies.

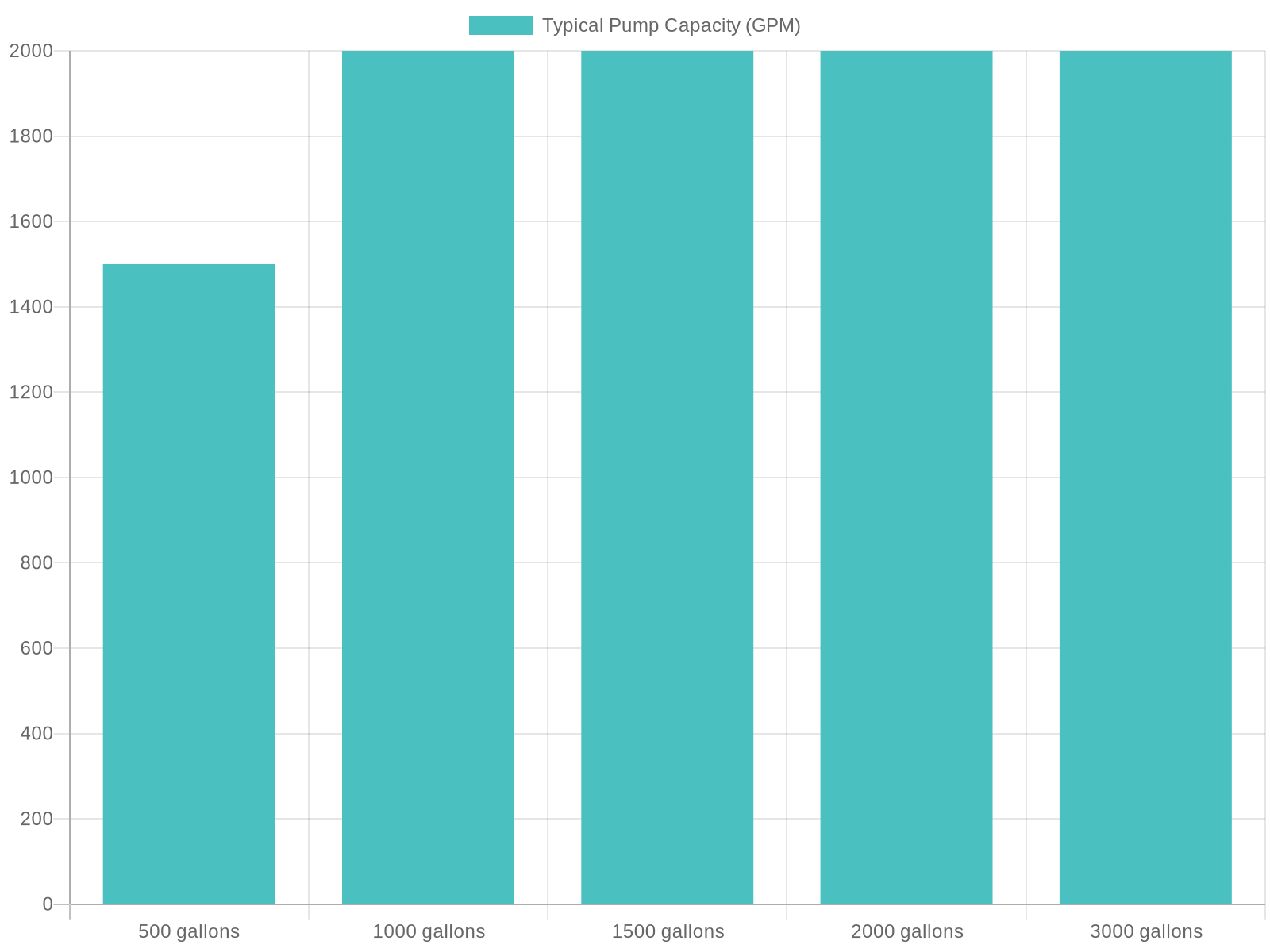

Visual Representation of Water Tank Sizes and Fire Suppression Effectiveness

The effectiveness of pumper fire trucks in fire suppression varies widely depending on their water tank size. The following table summarizes this relationship:

| Water Tank Size (gallons) | Typical Pump Capacity (GPM) | Notes |

|---|---|---|

| 500 | 1,000 – 1,500 | Standard municipal pumpers; can exhaust tank in approximately 30 seconds at full pump capacity. [fireengineering.com] |

| 1,000 | 1,250 – 2,000 | Larger municipal or rural pumpers; provides about 1 minute of water at full capacity. [firerescuetruck.com] |

| 1,500 | 1,500 – 2,000 | Used in areas with limited water sources; extends initial attack time before external supply is needed. [firerescuetruck.com] |

| 2,000 | 1,500 – 2,000 | Common in rural settings; allows for prolonged operations without immediate external water sources. [firerescuetruck.com] |

| 3,000 | 1,500 – 2,000 | Typically found in tanker trucks; supports extended firefighting efforts in remote areas. [firerescuetruck.com] |

This graph visually represents how water tank capacity aligns with pump capacity, indicating the critical role of tank size in determining the effectiveness of fire suppression efforts.

Key Safety Features in Pumper Fire Truck Design

Ensuring firefighter safety during operations is a critical consideration in the design of pumper fire trucks. Key safety features include reinforced cabs with rollover protection, providing essential protection in the event of an accident. The use of corrosion-resistant materials, such as marine-grade aluminum, enhances the durability of the vehicle in harsh environments.

Ergonomic equipment access systems, including swing-out trays and secure storage for self-contained breathing apparatus (SCBA), facilitate safer and more efficient tool retrieval, reducing injury risks. Advancements in pump control systems allow for precision flow regulation, improving operational safety during firefighting efforts.

Enhanced visibility provided by vehicle-mounted scene lighting and high-visibility markings ensures that first responders are easily seen, minimizing accidents at chaotic scenes. Finally, climate-controlled cabs equipped with HEPA filtration systems offer a safe and comfortable environment, reducing firefighters’ exposure to airborne contaminants.

These integrated features collectively enhance the overall safety and effectiveness of firefighters in emergency situations.

Conclusion

The thoughtful design of pumper fire trucks significantly enhances operational efficiency and firefighter safety. Every key feature, from chassis selection to pump capacity, water tank size, and safety mechanisms, plays a pivotal role in the overall functionality of these vehicles. A robust chassis supports essential firefighting equipment while ensuring durability in challenging conditions. High-capacity pumps paired with larger water tanks empower firefighters, enabling immediate and sustained responses to emergencies, crucial for controlling fires effectively.

Additionally, the integration of advanced safety features protects firefighters against job-related hazards. These aspects work synergistically to create a comprehensive apparatus, meticulously designed to meet the varied demands of firefighting scenarios while minimizing risks during operations. Every design decision made holds significant implications for the performance of fire departments in their community service. Therefore, a holistic approach in evaluating these elements is imperative to construct efficient pumper fire trucks that not only excel in fire suppression but also safeguard the lives of the brave individuals responding to emergencies.

In the high-stakes world of emergency response, the design of pumper fire trucks plays a critical role in ensuring swift and effective action. These specialized vehicles are often the first on the scene, making their configuration essential for operational efficiency and firefighter safety. Key considerations such as chassis selection, pump capacity, water tank size, and the layout of onboard storage directly influence a fire department’s ability to combat blazes and save lives. As we delve into the intricate aspects of pumper fire truck design, we will explore how each feature contributes to the overall effectiveness of these lifesaving apparatuses, underscoring the importance of tailored solutions that meet the unique challenges faced by firefighters today.

“Developing the right apparatus starts with asking the right questions.”

This quote emphasizes the critical thinking involved in the design process, urging designers and fire departments to identify their specific needs before selecting features.

Importance of Chassis Selection in Pumper Fire Truck Design

The selection in pumper fire truck design is fundamentally important, acting as the backbone of the vehicle and supporting all critical systems onboard. A well-chosen chassis contributes not only to the structural integrity but also to the overall functionality and operational effectiveness of the fire truck. Here are the key factors that should be considered during chassis selection:

- Weight Capacity: Fire trucks carry substantial loads including pumps, water tanks, hoses, and firefighting equipment. Therefore, selecting a chassis with a high weight capacity is essential to ensure it can support these heavy loads without compromising safety.

- Durability: Firefighting can be extremely demanding, often involving off-road conditions and inclement weather. A robust chassis made from durable materials will prolong the lifespan of the fire truck and reduce maintenance costs over time.

“Choosing the right powertrain is just as important as selecting the chassis.”

This quote highlights the interconnectedness of chassis and powertrain selection, which greatly impacts performance.

- Maneuverability: Fire scenes can often be chaotic, requiring fast and efficient maneuvering to position the truck correctly. A chassis designed for optimal handling and turning radius can significantly enhance operational effectiveness in navigating tight spaces and crowded environments.

- Compatibility with Equipment: Different fire departments may have unique equipment requirements. A chassis must be adaptable to accommodate various firefighting tools and technologies. This includes provisions for mounting pumps, hose reels, and other equipment crucial for firefighting missions.

- Height Considerations: The height of the chassis impacts the overall height of the truck, which is crucial for accessibility and operation. Chassis height affects not only the loading and unloading of equipment but also the ability to navigate under low bridges and overpasses.

- Ease of Access: Access to critical components for maintenance is vital for operational readiness. A well-designed chassis allows for easy access to the engine, transmission, and other key systems, facilitating quicker repairs and inspections.

In summary, the right chassis selection has a profound impact on the overall performance and efficiency of a pumper fire truck. It influences not only ability and safety during firefighting operations but also the longevity and maintainability of the truck itself. Consequently, fire departments must carefully evaluate their needs and the characteristics of available chassis options to ensure optimal performance in emergency situations.

The Importance of Water Tank Size in Pumper Fire Truck Design

In the critical realm of firefighting, the importance of water tank size in pumper fire trucks cannot be overstated. Fire departments rely on these vehicles as their front-line defense against fires, making the design choices vital for operational success. A larger water tank is invaluable, as it provides firefighters with the immediate water supplies needed to combat blazes effectively during the initial response phase.

“A larger tank gives firefighters more water support.”

This quote succinctly captures the significant advantage provided by larger tank sizes.

When pumper fire trucks are deployed to an incident, the availability of water is often a determining factor in successful fire suppression. A fire can escalate quickly, making the speed and amount of water available essential. A truck equipped with a larger water tank can carry anywhere from 1,000 to 3,000 gallons of water or more, allowing for longer engagement times before needing to refill from a hydrant or other water source. This capability is particularly critical in rural or underserved areas where hydrants may be scarce or absent.

The relationship between water tank size and pump capacity is equally crucial. While pumps are rated to deliver impressive flows—often between 1,000 and 2,000 gallons per minute (GPM)—the size of the tank dictates how long this water can be put to use. A larger tank complements a high-capacity pump effectively, ensuring that firefighters can maintain a steady and robust flow of water during the initial firefighting phases.

In summary, the water tank size in pumper fire trucks is a critical component of effective firefighting design. It enables quick responses, supports extensive fire suppression efforts, and contributes significantly to the safety and efficiency of firefighting operations. Thus, careful consideration of tank size is paramount in designing apparatuses that meet the rigorous demands of fire emergencies.

Key Safety Features in Pumper Fire Truck Design

Ensuring firefighter safety during operations is a critical consideration in the design of pumper fire trucks.

“Choosing the right powertrain is just as important as selecting the chassis.”

This highlights the importance of safety in all design decisions. Key safety features include reinforced cabs with rollover protection, providing essential protection in the event of an accident. The use of corrosion-resistant materials, such as marine-grade aluminum, enhances the durability of the vehicle in harsh environments. Ergonomic equipment access systems, including swing-out trays and secure storage for self-contained breathing apparatus (SCBA), facilitate safer and more efficient tool retrieval, reducing injury risks. Advancements in pump control systems allow for precision flow regulation, improving operational safety during firefighting efforts. Enhanced visibility provided by vehicle-mounted scene lighting and high-visibility markings ensures that first responders are easily seen, minimizing accidents at chaotic scenes. Finally, climate-controlled cabs equipped with HEPA filtration systems offer a safe and comfortable environment, reducing firefighters’ exposure to airborne contaminants. These integrated features collectively enhance the overall safety and effectiveness of firefighters in emergency situations.

- Pump Capacity: Critical for efficient fire suppression, with ratings typically ranging from 500 to 3,000 gallons per minute, allowing swift delivery of water to extinguish fires effectively. Higher capacities enable firefighters to tackle large fires without delay.

- Operational Efficiency: Enhanced by proper chassis selection, which ensures durability, weight capacity, and maneuverability, allowing fire trucks to navigate challenging environments and carry vital equipment securely.

- Water Tank Size: Larger tanks (1,000 to 3,000 gallons) provide essential support during initial response phases, extending engagement times before needing to refill. This is especially important in rural areas with limited water access.

- Firefighter Safety Features: Incorporating reinforced cabs, ergonomic equipment access, and high-visibility lighting is crucial. These features protect firefighters during operations and improve their effectiveness in emergencies.

- Importance of Design Customization: Tailored design features can meet specific operational needs and optimize performance under different scenarios. Data-driven design can significantly enhance the effectiveness of pumper fire trucks.

Each of these points underscores the importance of thoughtful pumper fire truck design in supporting firefighters’ missions and enhancing community safety.

The Importance of Water Tank Size in Pumper Fire Truck Design

In the critical realm of firefighting, the importance of water tank size in pumper fire trucks cannot be overstated. Fire departments rely on these vehicles as their front-line defense against fires, making the design choices vital for operational success. A larger water tank is invaluable, as it provides firefighters with the immediate water supplies needed to combat blazes effectively during the initial response phase.

Enhanced Emergency Support

When pumper fire trucks are deployed to an incident, the availability of water is often a determining factor in successful fire suppression. A fire can escalate quickly, making the speed and amount of water available essential. A truck equipped with a larger water tank can carry anywhere from 1,000 to 3,000 gallons of water or more, allowing for longer engagement times before needing to refill from a hydrant or other water source. This capability is particularly critical in rural or underserved areas where hydrants may be scarce or absent.

Moreover, with the ability to tap into vast stores of water, firefighters can initiate aggressive attack strategies that can significantly limit fire spread and ultimately save lives and property. For instance, if a pumper truck runs low on water, it may need to retreat to refill, consequently losing valuable time where every second counts.

Relationship with Pump Capacity

The relationship between water tank size and pump capacity is equally crucial. While pumps are rated to deliver impressive flows—often between 1,000 and 2,000 gallons per minute (GPM)—the size of the tank dictates how long this water can be put to use. A larger tank complements a high-capacity pump effectively, ensuring that firefighters can maintain a steady and robust flow of water during the initial firefighting phases.

For example, if a pumper truck features a 1,500 GPM pump but only carries a 500-gallon tank, it can quickly deplete its resources in just a matter of minutes. Conversely, a larger tank allows for sustained output, enabling firefighters to continue dousing flames without the immediate need to find refills.

Alongside pump ratings, water tank size also influences how fire departments prepare for various scenarios and emergencies, ensuring that they are equipped to deal with the unpredictability of fire situations. Firefighters are better positioned to respond to larger fires or multiple incidents when they have the water resources available to tackle the risks head-on.

In conclusion, the water tank size in pumper fire trucks is a critical component of effective firefighting design. It enables quick responses, supports extensive fire suppression efforts, and contributes significantly to the safety and efficiency of firefighting operations. Thus, careful consideration of tank size is paramount in designing apparatuses that meet the rigorous demands of fire emergencies.

At this point, as we shift focus towards safety features, it becomes clear that the operational capabilities provided by a large water tank must be complemented by robust safety measures. Firefighters, while responding to emergencies with available water, must also have protections in place that ensure their well-being during the demanding operations. Therefore, understanding the importance of safety features in pumper fire truck design is fundamental, as they nurture a safe and effective working environment for our first responders.

Key Safety Features in Pumper Fire Truck Design

Ensuring firefighter safety during operations is a critical consideration in the design of pumper fire trucks. Key safety features include reinforced cabs with rollover protection, providing essential protection in the event of an accident. The use of corrosion-resistant materials, such as marine-grade aluminum, enhances the durability of the vehicle in harsh environments. Ergonomic equipment access systems, including swing-out trays and secure storage for self-contained breathing apparatus (SCBA), facilitate safer and more efficient tool retrieval, reducing injury risks. Advancements in pump control systems allow for precision flow regulation, improving operational safety during firefighting efforts. Enhanced visibility provided by vehicle-mounted scene lighting and high-visibility markings ensures that first responders are easily seen, minimizing accidents at chaotic scenes. Finally, climate-controlled cabs equipped with HEPA filtration systems offer a safe and comfortable environment, reducing firefighters’ exposure to airborne contaminants. These integrated features collectively enhance the overall safety and effectiveness of firefighters in emergency situations.