Introduction

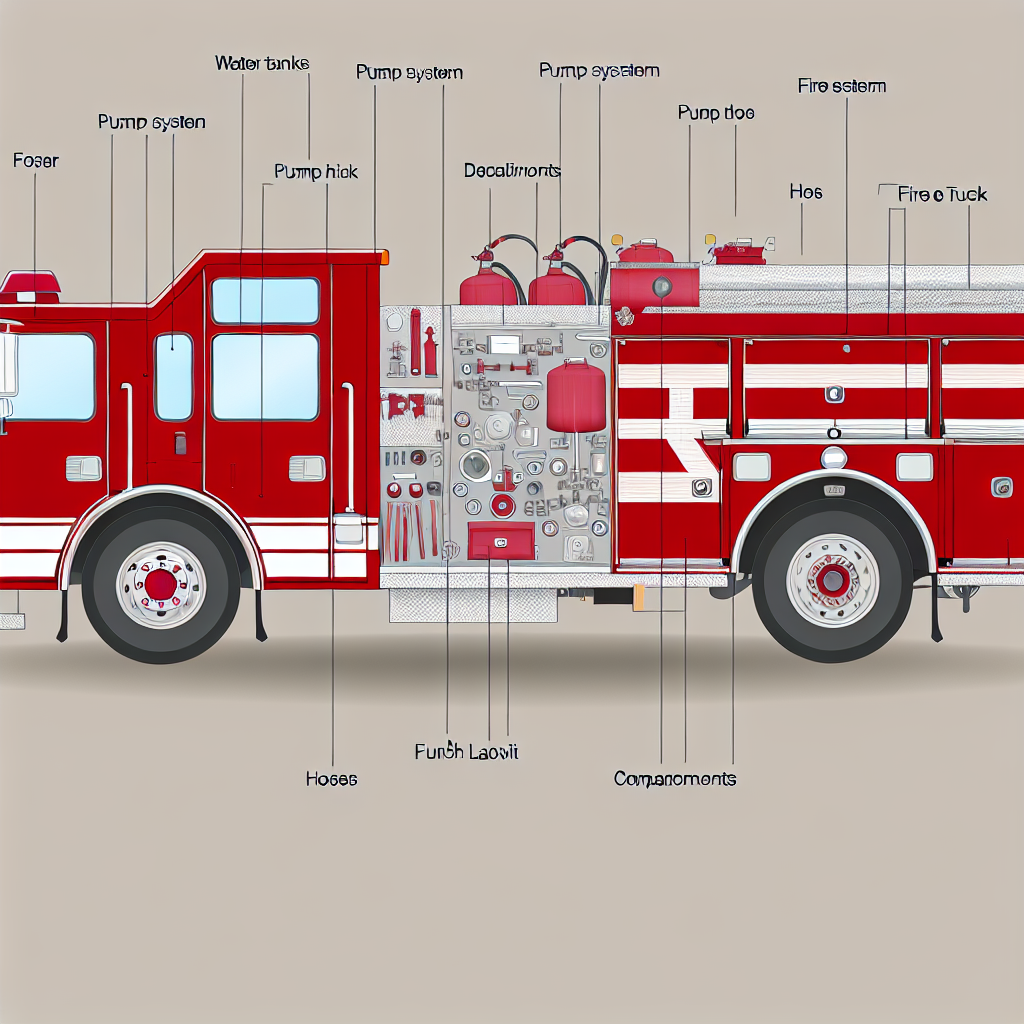

In the chaotic moments following a fire outbreak, timely and effective response can mean the difference between disaster and safety. Fire departments face numerous challenges, not the least of which is ensuring adequate water supply when it matters most. Alarming statistics reveal that approximately 30 percent of fire incidents run out of water before establishing a hydrant connection. This underscores the critical role that pump and tank specifications play in fire truck design.

The right specifications are not merely technical details; they are the backbone of effective fire suppression efforts. Equipped with the right pump capacity and water tank size, fire trucks enable firefighters to tackle blazes swiftly and efficiently, mitigating damage and saving lives. As departments continually assess their operational efficiency, understanding and optimizing these specifications is vital to overcoming the inherent challenges of emergency response.

Pump Capacity in Fire Suppression

Pump capacity is a critical factor in fire suppression, directly influencing a fire department’s operational effectiveness and efficiency. Fire pumps are typically rated between 500 and 3,000 gallons per minute (GPM), and selecting the right capacity is essential for meeting the specific demands of a department’s service area.

Impact of Pump Capacity on Fire Suppression:

-

Water Delivery and Fire Control:

Higher pump capacities enable the delivery of greater water volumes, which is vital for controlling large or rapidly spreading fires. For instance, pumps rated at 1,500 to 2,000 GPM can support multiple large-diameter hose lines and master streams, enhancing the ability to suppress significant fires effectively. [fireengineering.com]

-

Adaptability to Various Scenarios:

Departments operating in areas with high-rise buildings or industrial facilities may require pumps with higher capacities to ensure adequate water pressure and flow over extended distances or elevations. Two-stage pumps, which offer additional pressure performance, can be beneficial in such scenarios, allowing crews to switch between high-pressure and high-volume modes as needed. [piercemfg.com]

-

Compliance with Standards and Ratings:

The Insurance Services Office (ISO) evaluates fire departments based on their pump capacities relative to the Basic Fire Flow (BFF) requirements of their jurisdiction. For example, a community with a BFF of 1,750 GPM would need sufficient pump capacity to meet this demand, influencing the department’s ISO rating and potentially affecting insurance premiums for the community. [fireengineering.com]

Operational Considerations:

-

Water Supply Infrastructure:

The effectiveness of high-capacity pumps is contingent upon the availability of adequate water supply infrastructure. In areas with limited hydrant access or low-pressure systems, the benefits of a high-capacity pump may be diminished. Therefore, departments must assess their water supply capabilities when determining appropriate pump capacities. [fireapparatusmagazine.com]

-

Apparatus Design and Hose Management:

To fully utilize higher pump capacities, fire apparatus must be equipped with appropriately sized hoses and discharge outlets. For instance, large-diameter hoses (LDH) and 3.5- or 4-inch valves are necessary to handle increased water flow efficiently. Additionally, minimizing the number of 90-degree elbows in the hose layout can reduce friction loss and maintain optimal pressure. [fireengineering.com]

-

Staffing and Training:

Operating high-capacity pumps requires sufficient staffing and specialized training. Departments must ensure that personnel are adequately trained to manage the complexities associated with larger pumps, including hose deployment, pressure regulation, and coordination during multi-alarm incidents. [government-fleet.com]

Conclusion:

Selecting the appropriate pump capacity, ranging from 500 to 3,000 GPM, is a strategic decision that significantly impacts a fire department’s operational efficiency and effectiveness. It requires a comprehensive assessment of the community’s fire risks, water supply infrastructure, apparatus capabilities, and personnel resources. By aligning pump capacity with these factors, fire departments can enhance their ability to protect lives and property effectively.

Comparison of Common Pump and Tank Sizes

| Pump Capacity (GPM) | Tank Size (Gallons) | Typical Applications | Benefits |

|---|---|---|---|

| 750 | 500 | Residential and small commercial fires | Quick response with sufficient water supply |

| 1,500 | 1,000 | Mid-sized commercial and industrial fires | Greater water delivery for extended firefighting |

| 2,500 | 1,500 | Large-scale industrial and wildfires | High capacity for controlling large or rapidly spreading fires |

This table illustrates the common combinations of pump capacities and tank sizes utilized by fire departments, showcasing their various applications and inherent benefits. Fire departments can leverage this information to select equipment that meets their specific firefighting needs and operational scenarios.

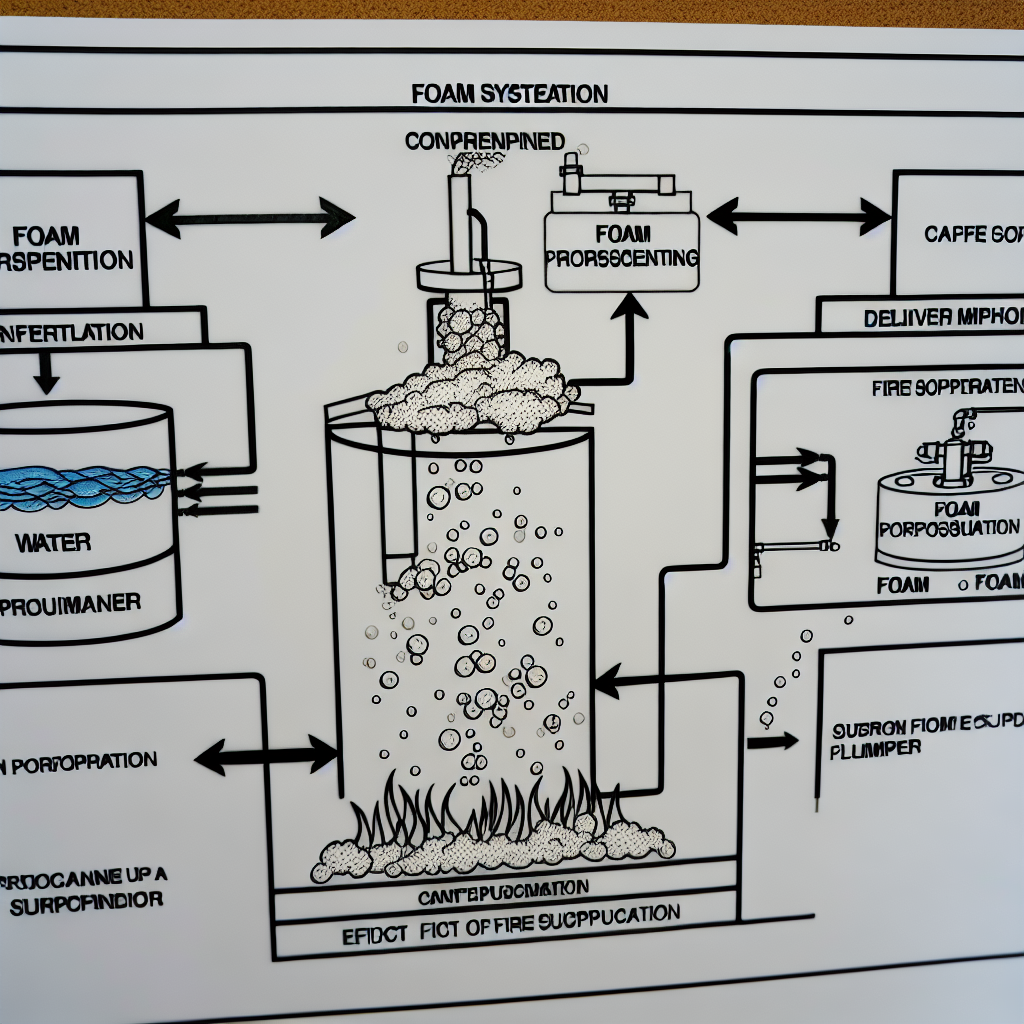

Importance of Foam Systems in Fire Suppression

Foam systems play a crucial role in enhancing fire suppression capabilities, particularly when dealing with specialized fires such as those involving flammable liquids, electrical equipment, or hazardous materials. These systems work by creating a blanket of foam that suffocates the fire and cools the surrounding fuel, providing a more effective method of suppression than water alone in certain scenarios.

Key Benefits of Foam Systems:

- Enhanced Fire Control: Foam systems are particularly useful in preventing reignition by creating a film that separates fuel from air. This film helps to inhibit the combustion process, which is especially critical when addressing flammable liquid fires.

- Versatility: Foam can be tailored for use in various contexts, including wildland fires, structural fires involving hazardous materials, and fires in industrial settings. This adaptability ensures that firefighters have the right tools for the job.

- Reduced Water Usage: In incidents where water supply is limited or where water could exacerbate the situation (such as chemical fires), foam systems significantly reduce the amount of water needed, thereby conserving resources and preventing further damage.

Integrating Foam Systems in Fire Truck Design:

The integration of foam systems within fire truck design enhances the vehicle’s operational efficiency and effectiveness. This integration allows firefighters to rapidly deploy foam in response to specialized incidents without needing a separate vehicle or extensive setup. Key considerations in the design include:

- Proportioning Systems: These systems ensure the correct mix of foam concentrate and water. Proper proportioning is essential for effective fire suppression.

- Delivery Methods: The method of foam delivery, whether through hoses, monitors, or compressed air foam systems (CAFS), can impact the speed and effectiveness of foam application in various scenarios.

‘Developing the right apparatus starts with asking the right questions.’

In conclusion, foam systems are vital for modern firefighting, particularly in specialized scenarios where traditional water suppression falls short. By incorporating these systems into fire truck design, departments can bolster their response capabilities, adapting to a diverse range of firefighting challenges and improving overall operational efficiency.

Water Tank Size in Fire Truck Operations with Outbound Links

The size of water tanks in fire trucks is a critical factor influencing their operational effectiveness, especially during high-volume incidents.

Standard Water Tank Size: 750 Gallons

A 750-gallon water tank is a common standard for many fire departments, particularly in urban and suburban settings. This capacity provides a balance between sufficient initial water supply and vehicle maneuverability. For instance, suburban pumpers often carry tanks ranging from 750 to 1,000 gallons, accommodating the need for a reliable water source while maintaining agility in varied environments. Fire Apparatus Magazine Cisterns for Fire Suppression

Importance of Water Tank Sizes in Fire Trucks

The size of a fire truck’s water tank directly impacts its ability to perform initial fire suppression, especially in areas lacking immediate access to external water sources like hydrants. Larger tanks enable prolonged firefighting efforts without the immediate need for external water supply, which is crucial in rural or remote areas. For example, rural departments often equip their pumpers with water tanks ranging from 1,500 to 3,000 gallons to compensate for the absence of hydrants. Fire Apparatus Magazine Advances in Sprinkler and Water Mist Fire Suppression Systems Tested

Considerations for Larger Tanks in High-Volume Incidents

In high-volume incidents, the demand for water increases significantly. Departments may opt for larger water tanks to meet this demand, but several factors must be considered:

- Vehicle Weight and Maneuverability: Larger tanks add weight, potentially affecting the vehicle’s handling and speed. Ensuring the chassis and suspension can support the additional weight is essential. Marion Body

- Pump Capacity: A larger tank should be paired with a pump capable of delivering higher flow rates to effectively utilize the increased water supply. Departments are specifying pumps with capacities up to 2,000 gallons per minute to match larger tanks. Fire Apparatus Magazine

- Operational Strategy: The choice between larger tanks and reliance on water tenders or hydrants depends on the department’s operational strategy and the typical scenarios they encounter. In areas with limited water sources, larger onboard tanks may be more advantageous.

In summary, while a 750-gallon tank is standard and suitable for many situations, larger tanks are beneficial in high-volume incidents, provided that considerations regarding vehicle design, pump capacity, and operational needs are addressed.

Additional Research

- The effectiveness of water mist fire suppression systems and their impact during firefighting incidents can be observed through scientific studies such as an evaluation published in the Journal of Fire Protection Engineering exploring their performance under various ventilation conditions. Examining Performance of Water Mist Fire Suppression Systems Under Ventilation Conditions

- A report on the optimization of water tank shapes offers insights into improving vehicle stability while maintaining adequate tank size. Optimization of Water Tank Shape in Terms of Firefighting Vehicle Stability

- Firefighting techniques using tank water have evolved, and larger tanks in fire trucks support these advancements, allowing departments to enhance response capabilities in challenging environments. Firehouse Article

These studies collectively highlight the critical role of water tank size and design in fire suppression strategies, emphasizing the need for optimization to enhance effectiveness, especially in areas with limited water resources.

Conclusion

In summary, the specifications for pumps and tanks in fire suppression systems are crucial for enhancing the operational effectiveness of fire departments. With pump capacities that typically range from 500 to 3,000 gallons per minute, selecting the right capacity is vital for addressing the unique firefighting demands of different communities. Coupling this with adequately sized water tanks—ranging from 750 to 3,000 gallons—allows fire trucks to deliver essential water supply during critical situations, particularly in areas where establishing a hydrant connection may be delayed.

A vivid example of the importance of proper pump and tank specifications is demonstrated by the effectiveness of the 1965 Mack Super Pumper System used by the New York City Fire Department. This truck, equipped with a powerful 600-horsepower engine and capable of delivering over 8,000 gallons per minute, was instrumental during a catastrophic fire in the Bronx. The pumper supplied multiple units with water simultaneously, showcasing how its capabilities significantly reduced the fire’s spread and mitigated potential losses.

Moreover, integrating foam systems can enhance fire suppression capabilities, proving essential in specialized incidents involving hazardous materials. As the statistics indicate, a significant number of incidents running out of water before hydrant connection highlights the need for appropriate equipment—a necessity that can dramatically improve response times and control during emergencies. By making strategic decisions regarding pump and tank specifications, fire departments not only bolster their ability to manage fires effectively but also improve overall operational efficiency in their response efforts. Ultimately, investing in the right apparatus equips firefighters with the tools they need to safeguard lives and property effectively, maximizing their impact during critical moments.

Final Thoughts on Fire Suppression Effectiveness

The importance of effective water management in fire suppression cannot be overstated. Statistics reveal that approximately 30 percent of incidents ran out of water before establishing a hydrant connection, underscoring the critical need for proper pump and tank specifications.

As fire departments continue to improve their operational strategies, focusing on pump capacities ranging from 500 to 3,000 gallons per minute and water tanks that can support these requirements is imperative. Therefore, as fire service professionals assess their equipment needs, keeping in mind the significance of adequate water supply and rapid deployment capabilities is essential for managing emergencies effectively and ensuring the safety of both the responders and the communities they serve.

Introduction

In the chaotic moments after a fire outbreak, a timely response can mean the difference between disaster and safety. Fire departments face many challenges, including ensuring they have enough water supply when it is most needed. Alarming statistics show that around 30 percent of fire incidents run out of water before they can connect to a hydrant. This highlights the critical role of pump and tank specifications in fire truck design. Choosing the right specifications is not just about technical details; they are essential for effective fire suppression efforts. With the right pump capacity and water tank size, fire trucks help firefighters respond swiftly and efficiently to fires. This capability mitigates damage and saves lives. As fire departments continue to assess their operational efficiency, understanding and optimizing these specifications is vital for overcoming challenges in emergency response.

Pump Capacity in Fire Suppression

Pump capacity is critical in fire suppression. It directly influences how effective and efficient a fire department can be. Fire pumps usually have ratings between 500 and 3,000 gallons per minute (GPM). Selecting the right capacity is essential for meeting the specific needs of a department’s service area.

Impact of Pump Capacity on Fire Suppression:

-

Water Delivery and Fire Control:

Higher pump capacities provide greater water volumes. This delivery is vital for controlling large or quickly spreading fires. For example, pumps rated at 1,500 to 2,000 GPM can support multiple large-diameter hose lines and master streams, enhancing the ability to suppress significant fires effectively. [fireengineering.com] -

Adaptability to Various Scenarios:

Departments in areas with high-rise buildings or industrial facilities may need pumps with higher capacities. This is essential for maintaining adequate water pressure and flow over long distances or heights. Two-stage pumps offer additional pressure performance and allow crews to switch between high-pressure and high-volume modes as needed. [piercemfg.com] -

Compliance with Standards and Ratings:

The Insurance Services Office (ISO) evaluates fire departments based on their pump capacities in relation to the Basic Fire Flow (BFF) requirements. For example, a community with a BFF requirement of 1,750 GPM needs a pump capacity that meets this demand. This evaluation affects the department’s ISO rating and potentially impacts insurance premiums for the community. [fireengineering.com]

Operational Considerations:

-

Water Supply Infrastructure:

High-capacity pumps need available water supply infrastructure to be effective. In areas with limited hydrant access or low-pressure systems, the benefits of high-capacity pumps may not be realized. Departments should assess their water supply capabilities when determining appropriate pump capacities. [fireapparatusmagazine.com] -

Apparatus Design and Hose Management:

To maximize high pump capacities, fire apparatus must have appropriately sized hoses and discharge outlets. For example, large-diameter hoses (LDH) and valves of 3.5 or 4 inches are necessary to handle increased water flow efficiently. Additionally, minimizing 90-degree elbows in the hose layout reduces friction loss and maintains optimal pressure. [fireengineering.com] -

Staffing and Training:

Using high-capacity pumps requires sufficient staffing and specialized training. Departments must train personnel to handle the complexities of larger pumps, including hose deployment, pressure regulation, and coordination during multi-alarm incidents. [government-fleet.com]

Conclusion:

Choosing the right pump capacity, ranging from 500 to 3,000 GPM, greatly affects a fire department’s efficiency and effectiveness. It requires a thorough assessment of the community’s fire risks, water supply infrastructure, apparatus capabilities, and personnel resources. By aligning pump capacity with these factors, fire departments can improve their ability to protect lives and property effectively.

Pump Capacity in Fire Suppression: Fire Truck Design

Pump capacity is a critical factor in fire suppression, directly influencing a fire department’s operational effectiveness and efficiency. Fire pumps are typically rated between 500 and 3,000 gallons per minute (GPM), and selecting the right capacity is essential for meeting the specific demands of a department’s service area.

Impact of Pump Capacity on Fire Suppression:

- Water Delivery and Fire Control:

Higher pump capacities enable the delivery of greater water volumes, which is vital for controlling large or rapidly spreading fires. For instance, pumps rated at 1,500 to 2,000 GPM can support multiple large-diameter hose lines and master streams, enhancing the ability to suppress significant fires effectively. [fireengineering.com] - Adaptability to Various Scenarios:

Departments operating in areas with high-rise buildings or industrial facilities may require pumps with higher capacities to ensure adequate water pressure and flow over extended distances or elevations. Two-stage pumps, which offer additional pressure performance, can be beneficial in such scenarios, allowing crews to switch between high-pressure and high-volume modes as needed. [piercemfg.com] - Compliance with Standards and Ratings:

The Insurance Services Office (ISO) evaluates fire departments based on their pump capacities relative to the Basic Fire Flow (BFF) requirements of their jurisdiction. For example, a community with a BFF of 1,750 GPM would need sufficient pump capacity to meet this demand, influencing the department’s ISO rating and potentially affecting insurance premiums for the community. [fireengineering.com]

Operational Considerations:

- Water Supply Infrastructure:

The effectiveness of high-capacity pumps is contingent upon the availability of adequate water supply infrastructure. In areas with limited hydrant access or low-pressure systems, the benefits of a high-capacity pump may be diminished. Therefore, departments must assess their water supply capabilities when determining appropriate pump capacities. [fireapparatusmagazine.com] - Apparatus Design and Hose Management:

To fully utilize higher pump capacities, fire apparatus must be equipped with appropriately sized hoses and discharge outlets. For instance, large-diameter hoses (LDH) and 3.5- or 4-inch valves are necessary to handle increased water flow efficiently. Additionally, minimizing the number of 90-degree elbows in the hose layout can reduce friction loss and maintain optimal pressure. [fireengineering.com] - Staffing and Training:

Operating high-capacity pumps requires sufficient staffing and specialized training. Departments must ensure that personnel are adequately trained to manage the complexities associated with larger pumps, including hose deployment, pressure regulation, and coordination during multi-alarm incidents. [government-fleet.com]

Importance of Emergency Response Systems

The importance of integrating emergency response systems cannot be overstated when designing fire trucks. The performance of a fire truck heavily relies on its pump capacity and the efficiency of its water supply systems, which are foundational in emergency situations. Firefighters must adapt quickly to the ever-changing demands of incidents, and thus each component must function synergistically within the emergency response framework. Departments should ensure that they have strategic systems in place for speedy accesses, such as centralized command systems, to oversee operations during a firefighting incident.

Incorporating Emergency Response Systems:

- Evaluating Equipment Needs: Assessing the demands of emergency response is crucial for selecting apparatus that can handle diverse situations effectively.

- Emergency Communication: Effective communication systems enhance operational efficiency and ensure that all personnel are aware of ongoing activities and resource needs.

- Training and Drills: Regular training on emergency response systems ensures that firefighters are prepared to act swiftly and effectively.

Water Tank Size in Fire Truck Operations

The size of water tanks in fire trucks is a critical factor influencing their operational effectiveness, especially during high-volume incidents.

Standard Water Tank Size: 750 Gallons

A 750-gallon water tank is a common standard for many fire departments, particularly in urban and suburban settings. This capacity provides a balance between sufficient initial water supply and vehicle maneuverability. For instance, suburban pumpers often carry tanks ranging from 750 to 1,000 gallons, accommodating the need for a reliable water source while maintaining agility in varied environments. [fireapparatusmagazine.com]

Importance of Water Tank Sizes in Fire Trucks

The size of a fire truck’s water tank directly impacts its ability to perform initial fire suppression, especially in areas lacking immediate access to external water sources like hydrants. Larger tanks enable prolonged firefighting efforts without the immediate need for external water supply, which is crucial in rural or remote areas. For example, rural departments often equip their pumpers with water tanks ranging from 1,500 to 3,000 gallons to compensate for the absence of hydrants. [fireapparatusmagazine.com]

Considerations for Larger Tanks in High-Volume Incidents

In high-volume incidents, the demand for water increases significantly. Departments may opt for larger water tanks to meet this demand, but several factors must be considered:

- Vehicle Weight and Maneuverability: Larger tanks add weight, potentially affecting the vehicle’s handling and speed. Ensuring the chassis and suspension can support the additional weight is essential. [marionbody.com]

- Pump Capacity: A larger tank should be paired with a pump capable of delivering higher flow rates to effectively utilize the increased water supply. Departments are specifying pumps with capacities up to 2,000 gallons per minute to match larger tanks. [fireapparatusmagazine.com]

- Operational Strategy: The choice between larger tanks and reliance on water tenders or hydrants depends on the department’s operational strategy and the typical scenarios they encounter. In areas with limited water sources, larger onboard tanks may be more advantageous.

In summary, while a 750-gallon tank is standard and suitable for many situations, larger tanks are beneficial in high-volume incidents, provided that considerations regarding vehicle design, pump capacity, and operational needs are addressed.