A&E Truck and Trailer Repair stands out as a leading provider of maintenance and repair services specifically tailored for truck and trailer operations. In an industry where reliability and safety are paramount, A&E focuses on ensuring medium and heavy-duty vehicles run smoothly and efficiently. For long-haul truck drivers and fleet managers, understanding the intricacies of truck systems is crucial for optimal performance. This article dives into the core offerings of A&E Truck and Trailer Services, technical insights into truck systems, and the company’s significant role in the broader industry context. Each chapter will illuminate key aspects of A&E’s services and their relevance to your operations, making this guide essential for anyone involved in trucking.

null

null

Steering Toward Reliability: Technical Insights into A&E Truck and Trailer Systems

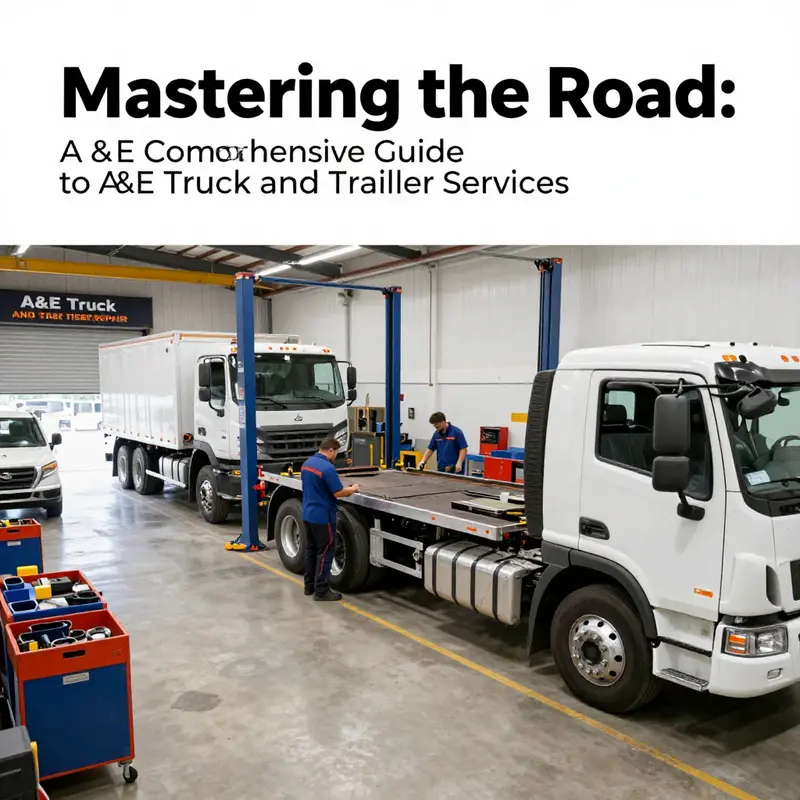

In the world of heavy-duty transport, reliability is a language spoken in maintenance bays, on long-haul interchanges, and within the routines fleets depend on every day. This chapter threads together practical insight with the broader technical framework that governs modern truck-and-trailer systems. It traces how a Houston-based shop like A&E Truck & Trailer Repair becomes a hub not merely for repair, but for the disciplined, end-to-end care that sustains safety, uptime, and efficiency across a fleet. The goal is not to catalog every component, but to illuminate how the integration of systems—brakes, drivetrains, steering, suspension, electrical networks, and environmental controls—demands a unified approach to diagnosis, service, and continuous learning. The path to reliability runs through a blend of theoretical understanding, hands-on expertise, and an adherence to factory-recommended procedures that honor the engineering behind each subsystem.

A central theme in contemporary truck maintenance is the shift from isolated repairs to systems thinking. Modern tractors and trailers, even when considered separately, behave as a coupled dynamic entity. When a trailer is hitched, weight distribution, dynamics during acceleration and braking, and even subtle steering inputs interact in real time. A technician who understands this coupling can foresee issues that might not be obvious when inspecting a single axle or a single brake line. This is where the guidance of comprehensive references, such as detailed visual guides that cover all major systems and their service procedures, becomes indispensable. The emphasis is on diagnosing using factory-recommended sequences and verifying that each subsystem functions within the prescribed tolerances. In practice, that means a technician does not simply replace a component; they validate the root cause, confirm the corrective action, and re-check the system under representative loading and road conditions. Such discipline is essential for fleets that depend on predictable schedules and costs.

In the day-to-day workflow, the maintenance philosophy mirrors the engineering of path-following and stability in advanced control systems, even though these are embedded in the vehicle’s electronics and software rather than in a laboratory. Modern control concepts, including state estimation and model-based planning, guide how the vehicle’s onboard computers interpret sensor signals to maintain stable operation during complex maneuvers. For instance, when a driver backs a trailer into a tight dock, the vehicle must reconcile wheel angles, brake pressures, and trailer alignment in a fraction of a second. Although technicians may not deploy a full control algorithm in the field, they benefit from understanding that such algorithms exist and that their real-world outcomes depend on the quality of sensing, calibration, and maintenance of actuators and links. This awareness translates into practical habits: meticulous calibration of steering gear, regular verification of sensor alignments, and a readiness to re-tune systems after any significant repair—an approach that preserves the fidelity of the vehicle’s responses when it matters most.

The electrification wave touching trailers adds another layer of complexity and opportunity. Electrified trailers promise more efficient energy management, better regenerative potential, and richer data streams about payload and dynamics. Yet they also raise questions about stability and coordination with the tractor. The technical challenge is to ensure that the powertrain, brakes, suspension, and hitching systems communicate seamlessly so that changes in weight distribution, wind gusts, or uneven surfaces do not destabilize the combination. For practitioners, this means embracing diagnostic practices that can interpret a wider set of signals—from battery health metrics to third-party sensors embedded in the trailer frame—without losing sight of the fundamentals: safe braking, predictable steering, and stable ride. The technician maintains a vigilant mindset, recognizing that new electrified subsystems must be integrated with the same rigor as traditional hydraulics and pneumatics. This integration is not a replacement of knowledge but an expansion of it, a reminder that the goal remains the same: safe, reliable operation across all modes of highway and yard work.

Maintenance culture, therefore, centers on accuracy, repeatability, and documentation. The most effective technicians treat every inspection as a structured, almost diagnostic ritual. They begin with a clean baseline—verified torque values, measured clearances, and up-to-date service logs—before proceeding to functional tests. They follow a sequence that ensures each subsystem is measured against factory-recommended procedures and that any deviation is interpreted not as a single fault but as a signal of potential chain effects elsewhere in the network. The emphasis on thoroughness is not pedantic; it is pragmatic. A small air-leak in the braking system or a marginal electrical connection can cascade into degraded ABS performance, reduced trailer stability, or uneven tire wear. By tracing the fault to its origin and validating corrective actions across the entire system, technicians protect uptime and reduce the likelihood of return visits that disrupt operations.

For a Houston enterprise like A&E Truck & Trailer Repair, the geographic and climate context also shapes maintenance priorities. The road network carries a mix of high-traffic corridors and industrial access routes that expose equipment to heat, humidity, and dust. In such a setting, the cadence of inspections—particularly for brakes, suspension components, and electrical harness integrity—must reflect both manufacturer recommendations and the realities of local operation. Fleet managers learn to plan preventive maintenance around peak demand periods, ensuring that critical components are in optimal condition before weather extremes or heavy loading intensify wear. The service narrative extends beyond reaction to include proactive education: technicians share insights with fleet operators about how seasonal load patterns affect weight distribution and how tire and brake wear can signal the need for more frequent service intervals. This collaborative approach to maintenance underscores the value of a trusted local partner that can translate abstract engineering principles into concrete, actionable routines.

The literature that guides this practice is intentionally practical and visually oriented. Textbooks and service manuals designed for automotive and diesel programs distill intricate concepts into service steps and diagnostic tips that align with real-world scenarios. In particular, the major systems—brakes, transmissions, drive axles, suspension, steering, electrical, and HVAC—are presented with procedures that reflect the factory’s recommended sequence. For technicians, this is more than a reference; it is a framework for building competence across the vehicle’s architecture. It also makes clear that even as new technologies emerge, the core skills of measurement, verification, and methodical problem-solving remain constant. In this sense, the technician’s toolkit is not simply a set of parts; it is an integrated method for preserving performance, safety, and efficiency under a spectrum of operating conditions.

Beyond the shop floor, the broader ecosystem of vehicle safety and efficiency continues to evolve through the convergence of intelligent transportation systems (ITS). ITS envisions a network where computers, sensing, and communications enable vehicles to monitor, evaluate, and adapt to traffic and infrastructure conditions. While much of ITS research targets connected infrastructure, fleets benefit from the downstream implications: better predictive maintenance, improved route planning, and enhanced incident response. The practical takeaway for A&E-like operations is that the data generated by modern vehicles—when interpreted by skilled technicians—can inform maintenance decisions long before a fault becomes visible during a road test. Telematics, on-board diagnostics, and remote monitoring systems all become part of a proactive maintenance culture rather than a reactive one. This convergence of vehicle health data with human expertise yields a robust uptime strategy, where repairs are planned, parts are stocked in anticipation, and drivers experience fewer unexpected disruptions.

In this environment, the technician’s role extends to education and mentorship. A shop that emphasizes ongoing training helps staff stay current with evolving standards and fault modes. The practical value is clear: a well-trained team can interpret subtle shifts in vehicle behavior, such as unusual trailer sway during crosswinds or a gentle drift in steering under light braking, as potential signs of incipient trouble. Training also supports a consistent service language—shared terminology, standardized inspection checklists, and uniform calibration procedures—that reduces miscommunication across shifts and with fleet managers. For a local operation in a dense market, such consistency is a competitive advantage. It ensures that when a fleet operator calls, they receive not only a repair but a transparent explanation of root causes, corrective actions, and measurable improvements in performance.

Within this framework, a simple, concrete practice can illustrate the fusion of theory and technique. When technicians examine the brake system, they do more than verify pad thickness and rotor condition; they assess the interaction of the entire braking chain with the trailer’s weight distribution and the tractor’s load profile. The same applies to the electrical system: a wire harness is not simply a bundle of conductors but a pathway for signals that govern braking force, stability control, and environmental comfort. This holistic testing mindset—checking for consistency across subsystems, rechecking after adjustments, and confirming that each subsystem returns to its expected state—reduces the chance of intermittent faults that frustrate drivers and erode reliability. It is a discipline worth sustaining, especially in environments where the line between a small maintenance item and a major downtime incident is thin and easily crossed if attention falters.

To connect these ideas with the day-to-day business of A&E Truck & Trailer Repair, consider how the service philosophy translates into customer outcomes. A fleet manager expects predictable performance, safe operation, and clear communication when issues arise. Technicians who can articulate how a diagnostic finding relates to real-world performance—why a certain vibration occurs, how it ties to wheel alignment, and what the corrective action entails—build trust. The Houston context sharpens this requirement: local fleets often rely on timely responses to weather-driven maintenance needs, immediate availability of common repair parts, and a clear, actionable plan for returning equipment to service. When a technician explains that a particular diagnostic sequence mirrors the factory method for verification and validation, the manager gains confidence in the recommended service and its potential to extend vehicle life and uptime. This is the essence of a service partner that not only fixes problems but also educates, plans, and safeguards operators against recurring faults.

A final thread in this narrative is the value of accessible, structured knowledge for both technicians and fleet operators. The shared understanding—rooted in recognized procedures, visual guides, and practical experience—creates a common ground from which improvements can emerge. The takeaway for readers who manage or operate A&E-style services is clear: invest in training, maintain meticulous records, and embrace a problem-solving approach that treats every fault as an opportunity to reinforce the vehicle’s system-wide resilience. In doing so, the organization remains responsive to evolving technologies while staying faithful to the enduring engineering principles that make trucks and trailers reliable workhorses on America’s roads. The payoff is measured not only in uptime but in the confidence that comes with knowing the driving force behind every mile is sound maintenance, disciplined diagnostics, and a culture of continuous learning.

For readers who want to explore hands-on maintenance concepts further, consider the resource that blends practical maintenance training with applied service strategy at fire-truck-focused contexts, which can offer transferable insights into disciplined maintenance practices across heavy-duty fleets. fire-truck-maintenance-service-training

External resource: https://www.nhtsa.gov/road-safety

null

null

Final thoughts

A&E Truck and Trailer Repair not only provides vital maintenance and repair services but also plays a key role in the safety and reliability of long-haul trucking. Through the insights provided in this article, you can appreciate the comprehensive offerings of A&E, understand the intricacies of truck systems, and recognize the company’s place within the larger trucking industry. Whether you’re a truck driver, fleet manager, or technician, partnering with A&E will enhance your operational efficiency and ensure that you stay on the road safely and confidently.