As flames engulf buildings and lives hang in the balance, few sights are more reassuring than a sleek, powerful fire truck racing to the rescue. Over the decades, the design of pumper fire trucks has evolved dramatically, embracing innovation to meet the growing demands of emergency response. In fact, the National Fire Protection Association (NFPA) reports that in 2023, U.S. fire departments responded to a fire every 23 seconds, making rapid response crucial. Today’s fire trucks are not only equipped to deliver water but are also engineered with cutting-edge features that enhance operational efficiency and ensure the safety of firefighters. From advanced pump capacities to improved vehicle ergonomics, each design aspect plays a crucial role in shaping an effective emergency response. As we delve into the world of pumper fire truck design, we will explore how these innovative features are revolutionizing the way firefighters operate in high-pressure situations, ultimately saving lives and protecting properties.

A fire truck on an emergency response, highlighting its design and the urgent atmosphere of firefighting operations.

Key Design Features of Pumper Fire Trucks

- Pump Capacity: The pump capacity determines how quickly and effectively water can be delivered to the scene. Ratings can vary from 500 to 3,000 gallons per minute, significantly affecting the truck’s ability to combat large fires.

- Water Tank Size: A standard tank holds around 750 gallons, but having a larger tank can ensure sufficient water supply during the critical initial moments of an incident before a hydrant connection is established.

- Chassis Selection: The choice of chassis impacts the overall maneuverability, strength, and durability of the fire truck. It needs to withstand the demanding conditions of emergency response and can affect the driveability in various terrains.

- Equipment Accessibility: Ensuring that equipment is easily and quickly accessible improves response times. Proper design can facilitate rapid deployment of tools, hoses, and other firefighting equipment by firefighters at the scene.

- Ergonomics and Storage Solutions: Deploying equipment in a manner that considers firefighter ergonomics minimizes injury and enhances efficiency. Well-designed storage solutions ensure that tools are secure, organized, and accessible during emergency operations.

- Foam Systems: Integrating foam systems into the pumper can enhance firefighting capabilities, especially in tackling flammable liquid fires. Foam attachment systems allow for rapid application in high-risk situations, enabling a more versatile approach to firefighting.

An innovative modern pumper fire truck highlights its design and features, showcasing the advanced capabilities that enhance performance in emergency scenarios.

The Importance of Pump Capacity in Pumper Fire Truck Design

Pump capacity is a critical factor in the design of pumper fire trucks as it directly influences their efficiency and effectiveness in emergency situations. Firefighting is often a race against time, and having a reliable pump capacity can mean the difference between life and death.

The pump ratings of fire trucks typically range from 500 to 3,000 gallons per minute (GPM). This range accommodates various operational needs, allowing fire departments to select vehicles that best suit their specific challenges. For instance, a higher pump capacity is crucial when combating large fires that require immediate and significant water output. Fire departments must assess their typical incident types when choosing pump capacity, as some may need lower ratings for residential areas, while others may require higher ratings for industrial settings or wildfires.

The impact of pump capacity on emergency response cannot be overstated. During the initial moments of an emergency, it is essential for firefighters to have an adequate water supply to suppress flames. A pumper fire truck with a robust pump capacity can deliver large volumes of water immediately, maximizing firefighting efforts before the establishment of a hydrant connection. This is particularly vital in scenarios where water supply is uncertain or delayed. For example, incidents where fire trucks must operate independently from existing water sources highlight the necessity of having an onboard water tank capable of sustaining firefighting needs.

Moreover, the relationship between pump capacity and firefighting efficiency is clear. In emergencies, time is critical; the faster and more effectively firefighters can deploy water, the greater their chance of extinguishing the fire before it spreads. These operational efficiencies gained from adequate pump capacity not only improve safety outcomes but also reduce property damage during incidents, showcasing the importance of thoughtful pump design in fire truck engineering.

In summary, selecting the right pump capacity is vital for enhancing the performance of pumper fire trucks and ensuring that fire departments can respond effectively to a variety of emergencies. This consideration in design is a core element of operational readiness and the efficacy of firefighting efforts.

Comparison of Pump Capacities in Different Pumper Fire Truck Models

| Fire Truck Model | Pump Capacity (GPM) | Water Tank Size (Gallons) | Typical Performance Outcome |

|---|---|---|---|

| Pierce Enforcer | 1,500 | 750 | Rapid response, suited for urban firefighting |

| Oshkosh Striker | 2,000 | 1,000 | Effective for large-scale industrial fires |

| Rosenbauer Commander | 1,250 | 800 | Versatile performance in rural and suburban settings |

| E-ONE Cyclone | 3,000 | 1,500 | Ideal for wildland firefighting and large-volume attacks |

| KME Predator | 1,750 | 1,000 | Balanced performance for residential and commercial fires |

This table illustrates how different pumper fire truck models vary in pump capacities and water tank sizes, showcasing their respective capabilities and effectiveness in varying fire emergency scenarios. Higher pump capacities generally contribute to enhanced performance outcomes in critical situations, making thoughtful selection essential for fire departments looking to optimize their firefighting strategies.

Tank Size Considerations in Pumper Fire Truck Design

When designing pumper fire trucks, one of the most critical aspects that fire departments must consider is the size of the water tank. While the standard capacity is typically 750 gallons, increasing this capacity can offer substantial benefits in operational success.

Firefighters often respond to emergencies where they may need to operate for significant lengths of time before a reliable water source, such as a fire hydrant, is available. In these situations, having a larger onboard water supply can be vital. For instance, expanding the water tank capacity to 1,000 or even 1,500 gallons can allow fire crews to suppress flames more effectively during those crucial initial moments. This increased capacity ensures that firefighters have adequate water to combat blazes swiftly, preventing the fire from escalating and ultimately saving lives and property.

The ideal tank size can vary significantly based on a few factors, including geographic area, typical types of emergencies encountered, and anticipated water requirements for various fire scenarios. In rural regions or areas lacking a dense network of hydrants, larger tanks can facilitate a more efficient firefighting effort, allowing teams to maximize their ability to fight fires without delay.

Moreover, larger tanks can often accommodate advanced firefighting technologies, such as foam systems. These systems can be crucial for specific fire types, giving fire departments a versatile toolset to enhance firefighting efforts.

In conclusion, tank size is a fundamental consideration in the design of pumper fire trucks. It not only impacts water capacity but also plays a crucial role in enabling optimal operational effectiveness during emergency responses.

The Significance of Equipment Storage in Pumper Fire Truck Design

In the realm of firefighting, effective organization and storage of equipment play a crucial role in enhancing operational efficiency. The quote, “How equipment is stored on a pumper matters just as much as how much it can carry,” emphasizes the importance of thoughtful equipment placement and storage solutions within pumper fire trucks.

Properly designed storage solutions ensure that vital tools, hoses, and firefighting gear are easily accessible to firefighters during high-pressure scenarios. This not only contributes to faster response times but also significantly influences safety and efficiency on the ground. By integrating practical storage options, fire departments can minimize confusion and streamline the process of deploying equipment, which can be critical when every second counts.

Additionally, effective storage arrangements can help maintain the integrity and condition of the equipment over time. With well-organized compartments that secure gear and tools, fire trucks can prevent unnecessary wear and tear, ensuring that essential equipment is always in optimal working condition.

In summary, the way equipment is stored on a pumper is a fundamental aspect of its design that reflects the operational needs of firefighting teams. By investing in innovative storage solutions, fire departments can enhance efficiency, improve safety, and ultimately save lives in emergency situations.

The Significance of Equipment Storage in Pumper Fire Truck Design

In the realm of firefighting, effective organization and storage of equipment play a crucial role in enhancing operational efficiency. The quote, “How equipment is stored on a pumper matters just as much as how much it can carry,” emphasizes the importance of thoughtful equipment placement and storage solutions within pumper fire trucks.

Properly designed storage solutions for emergency response vehicles ensure that vital tools, hoses, and firefighting gear are easily accessible to firefighters during high-pressure scenarios. This not only contributes to faster response times but also significantly influences safety and efficiency on the ground. By integrating practical storage options, fire departments can minimize confusion and streamline the process of deploying equipment, which can be critical when every second counts.

Additionally, effective storage arrangements can help maintain the integrity and condition of the equipment over time. With well-organized compartments that secure gear and tools, fire trucks can prevent unnecessary wear and tear, ensuring that essential equipment is always in optimal working condition.

In summary, the way equipment is stored on a pumper is a fundamental aspect of its design that reflects the operational needs of firefighting teams. By investing in innovative storage solutions, fire departments can enhance efficiency, improve safety, and ultimately save lives in emergency situations.

Firefighter Safety Features in Pumper Fire Trucks

Firefighter safety is paramount in fire truck design, particularly in pumper fire trucks that are often first on the scene of an emergency. Various design elements are thoughtfully integrated to enhance overall safety and operational efficiency.

Ergonomic Considerations

An essential aspect of pumper fire truck design includes ergonomic considerations. The layout of controls, seats, and compartments is designed to reduce strain on firefighters, allowing them to perform their duties effectively, even under stress. For instance, adjustable seating can accommodate firefighters of different sizes, while strategically placed controls minimize the need to reach excessively, enhancing response times and reducing the risk of injury.

Storage Solutions

Effective storage solutions are critical for maintaining firefighter safety. Adequately designed compartments allow for organized storage of tools and gear, reducing clutter and ensuring that everything is easily accessible. This organization mitigates the risk of equipment becoming damaged or misplaced, which can become a serious issue during emergencies when every second counts. Additionally, sealed compartments can help protect sensitive equipment from water damage and other environmental factors.

Ease of Access to Equipment

Rapid access to equipment is crucial during emergencies, and pumper fire trucks are designed with this in mind. Features such as side roll-up doors and slide-out trays enable firefighters to retrieve equipment swiftly. Accessibility is further improved with color-coded and labeled compartments, allowing firefighters to quickly locate essential tools without fumbling, potentially saving lives and property in urgent situations.

In conclusion, the incorporation of safety features—from ergonomic designs to efficient storage and equipment accessibility—plays a vital role in the effectiveness of pumper fire trucks, ensuring firefighters can perform their duties safely and efficiently during emergencies.

Conclusion

In conclusion, the design of pumper fire trucks plays a crucial role in enhancing the performance of firefighting operations. Here are the key innovations that contribute to improved efficiency in emergency response:

- Innovative Pump Capacities: Ranging from 500 to 3,000 gallons per minute, these ensure firefighters can quickly deliver ample water to combat flames in life-threatening situations.

- Larger Water Tanks: Allow for sustained firefighting efforts during the initial moments before connecting to a hydrant, significantly improving operational success.

- Effective Equipment Storage Solutions: Ensures essential tools are readily accessible, minimizing confusion during emergencies and enabling faster response times.

- Integrated Safety Features: Ergonomic controls and easily accessible compartments enhance the wellbeing and efficiency of firefighters during operations.

Collectively, these innovative design elements not only enhance the performance of pumper fire trucks but also elevate the effectiveness of firefighting efforts overall. As technology continues to evolve, the design and engineering of these vital response vehicles will remain central to saving lives and protecting communities during emergencies.

Summary of User Adoption Data for Pumper Fire Truck Designs

Recent studies and reports highlight significant trends in the adoption of advanced pumper fire truck designs among fire departments, showcasing improvements in operational performance and firefighter safety:

-

General Adoption and Safety Features:

According to the NFPA’s 2020 report, 71% of fire departments now operate pumper trucks manufactured within the last 15 years. This trend corresponds with a notable decrease in injury incidents—40% fewer—attributed to advancements in cab designs, rollover protection, and enhanced braking systems. -

Safety System Integration:

The Fire Apparatus Manufacturers’ Association (FAMA) reported an increase in new pumper orders that include integrated safety systems, such as emergency braking and stability control, from 45% in 2018 to 85% in 2023. -

Water Tank Size and Firefighting Efficiency:

A notable trend is emerging towards specifying larger water tanks, with a 30% rise in orders for tanks exceeding 1,000 gallons, and 65% of departments opting for Compressed Air Foam Systems (CAFS). These changes are enhancing firefighting capabilities while minimizing water usage during operations. -

Operational Efficiency Improvements:

A recent study by the International Association of Fire Chiefs revealed that newer pumper designs (post-2017) lead to 28% faster water deployment times and a 22% reduction in setup errors, significantly elevating operational efficiency. -

Usage of Electronic Systems:

Urban fire departments are increasingly adopting pumpers with electronic pressure control systems, with a 92% adoption rate noted. This shift has resulted in a 40% reduction in pressure-related equipment failures and a 50% increase in pump engagement speeds.

These findings reflect a positive trajectory in the adoption of innovative pumper fire truck design features, underscoring enhancements in both performance and safety for firefighting operations.

Comparison of Pump Capacities and Performance Outcomes

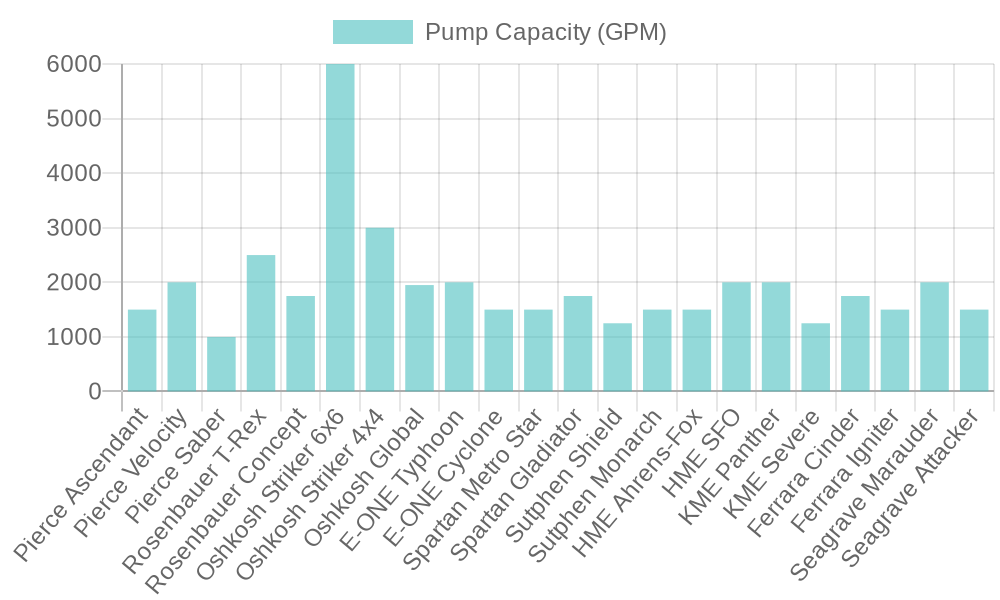

To provide a clearer understanding of how different pump capacities affect firefighting performance, the following graph illustrates the performance outcomes of various fire truck models:

This graph depicts several models alongside their pump capacities (in gallons per minute). As observed, higher pump capacities are typically associated with larger water tank sizes, contributing to enhanced operational efficiency in emergency situations. This clear visual representation helps emphasize the importance of selecting appropriate pump specifications based on the firefighting needs of each fire department.

Source: Fire Trucks Comparison Guide 2025 | Pierce vs Rosenbauer vs Oshkosh | HVI App

The careful selection and understanding of pump capacities are vital for optimizing pumper fire truck performance and ensuring efficiency during firefighting operations.