Understanding the key features in Pumper Fire Truck Design is crucial for fire departments aiming to enhance firefighter safety and overall operational efficiency. With the unique demands of each community, pumper fire trucks must be customized to meet specific operational needs, ensuring that they perform efficiently when time is of the essence. The decisions made during the design process directly influence not only the effectiveness of these vehicles but also the safety of the firefighters who depend on them. From pump ratings to hose bed accessibility, thoughtful considerations can maximize firefighting efficiency in tactical scenarios, ultimately saving lives and properties. As the first responders to emergencies, having well-designed apparatus that aligns with strategic priorities can make all the difference in combating fires effectively.

Conclusion

In conclusion, the design of pumper fire trucks holds significant importance for firefighter safety and operational efficiency. Key features such as chassis and engine selection, water tank size, pump ratings, hosebed accessibility, and ladder design must be considered meticulously. Each aspect plays a vital role in enhancing response capabilities, ensuring that firefighters can act swiftly and effectively in emergencies. For fire departments, prioritizing these elements during the design process is essential to meet both community demands and safety standards. As critical first responders, investing in properly designed apparatus can lead to better outcomes, ultimately saving lives and property when it matters most. Therefore, let us take these insights to heart and apply them in practice, fostering a culture of safety and efficiency in fire service operations.

Chassis and Engine Selection

- Durability and Reliability: The chassis and engine must withstand demanding conditions, ensuring operational continuity during emergencies.

- Power and Torque: Choose engines like the PACCAR MX-13 with 405-510 horsepower and 1,450-1,850 lb-ft of torque for effective navigation and quick response.

- Fuel Efficiency: Engines should ensure high fuel economy, like the PACCAR MX-13’s advanced fuel injection technology, to reduce refueling concerns.

- Serviceability: Design for easy maintenance access to reduce downtime, exemplified by the PACCAR MX-13’s integrated maintenance systems.

- Weight Considerations: The chassis must support firefighting equipment weight without sacrificing maneuverability.

- Environmental Compliance: Ensure engine emissions meet EPA standards, as required in modern firefighting operations.

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Tank Size | Typical sizes range from 500 to 1,500 gallons | A larger tank allows for extended firefighting without immediate water supply, reducing refill time at the scene. |

| Pump Capacity | Ranges from 500 to 3,000 gallons per minute | Higher pump capacities enable faster water delivery to the fire, crucial for effective firefighting. |

| Hosebed Height | Heights typically vary between 30 to 48 inches | Lower hosebed heights facilitate quicker access to hoses, enhancing response times during emergencies. |

| Storage Options | Includes compartmentalization for equipment storage | Efficient storage maximizes space and organization, allowing quick access to tools and preventing delays in emergencies. |

Hosebed Height and Accessibility

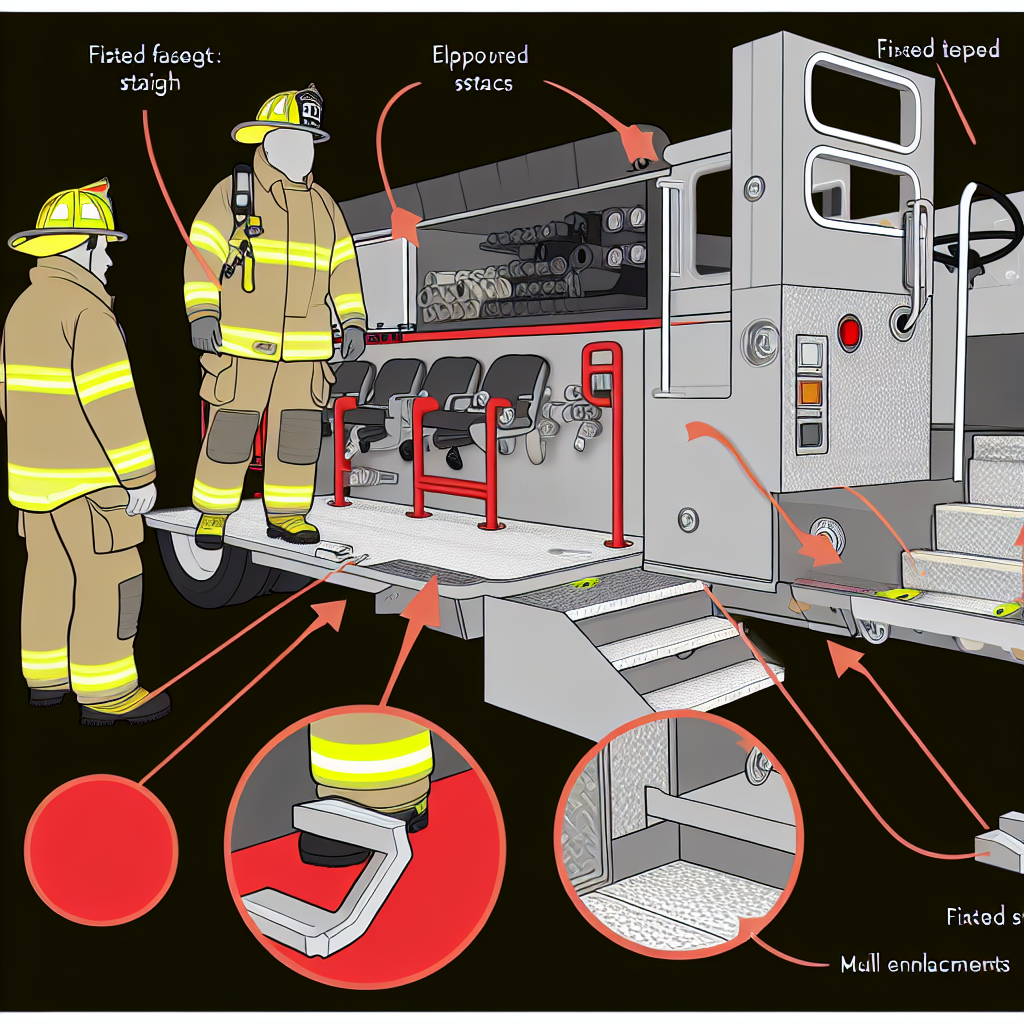

The height of the hosebed is a crucial aspect of pumper fire truck design, greatly impacting how quickly and effectively firefighters can respond to emergencies. A lower hosebed height typically allows for faster and safer hose deployment, reducing the physical strain on firefighters and minimizing the risk of injury. As highlighted by industry experts, “Developing the right apparatus starts with asking the right questions.” This means that fire departments must make informed decisions about hosebed height to align with their operational needs and safety protocols.

Best practices in hosebed design prioritize accessibility. For instance, utilizing L-shaped water tanks can lower hosebeds, making hoses easier to access without requiring firefighters to climb or stretch excessively. Such configurations allow firefighters to load and unload hoses safely from the ground or with minimal elevation.

To further enhance accessibility, designs should incorporate features like fixed steps and full-height handrails alongside the truck, facilitating safe movement around the fire apparatus. Additionally, specifying clear hose load requirements regarding types, lengths, and couplings ensures that the hosebed is adequately designed for quick access to essential equipment during emergencies.

Safety measures are also vital; incorporating slip-resistant surfaces and ensuring grab handles are positioned to provide secure holds while working can significantly reduce the risk of accidents. By emphasizing ergonomic access and considering the specific needs of firefighters, departments can optimize their hosebed designs, ultimately improving both the safety and efficiency of their emergency response capabilities.

Water Tank Size and Pump Ratings

The design of fire trucks, particularly the size of their water tanks and the ratings of their pumps, plays a crucial role in firefighting efficiency. These elements determine how effectively a fire department can respond to various emergencies, especially in areas with limited water supply.

Water Tank Size

The capacity of a fire truck’s water tank dictates the duration firefighters can operate before requiring an external water source. In urban settings with abundant hydrants, smaller tanks are common, while rural areas necessitate larger tanks due to limited water access.

- Urban Pumper Trucks: Typically equipped with water tanks ranging from 500 to 1,000 gallons.

- Rural Fire Engines: May carry up to 2,000 gallons to compensate for the lack of nearby hydrants.

- Water Tenders: Designed to transport large volumes of water, these vehicles can carry between 1,500 to over 5,000 gallons, ensuring a steady water supply in areas without hydrants.

Pump Ratings

The pump’s capacity, measured in gallons per minute (GPM), determines how quickly and effectively water can be delivered to combat fires. Higher pump ratings are essential for large-scale fires or situations requiring substantial water flow.

- Standard Municipal Pumpers: Typically feature pumps rated between 1,000 and 1,500 GPM, balancing performance and vehicle size.

- High-Capacity Pumpers: Used in industrial settings or airports, these can exceed 3,000 GPM to address significant fire risks.

Impact on Firefighting Efficiency

The interplay between water tank size and pump capacity directly affects a fire department’s operational effectiveness:

- Initial Attack Capability: Adequate onboard water allows firefighters to begin suppression efforts immediately upon arrival, crucial in areas lacking hydrants.

- Sustained Operations: A robust pump ensures continuous water delivery, maintaining pressure and flow necessary to control and extinguish fires.

- Mobility and Accessibility: While larger tanks and pumps enhance firefighting capacity, they also increase vehicle weight and size, potentially limiting maneuverability, especially in urban environments.

In summary, selecting appropriate water tank sizes and pump ratings is vital for tailoring fire trucks to the specific needs of the communities they serve, ensuring both rapid response and sustained firefighting capabilities.

For fire departments looking to enhance their operations, understanding and adhering to established fire safety standards is vital. The following links provide authoritative information on fire safety regulations:

- Occupational Safety and Health Administration (OSHA)

This site offers a wealth of information on fire protection standards relevant across various industries. - National Fire Protection Association (NFPA)

The NFPA is renowned for its comprehensive fire safety standards that set the foundation for fire protection regulation. - United States Fire Administration (USFA)

The USFA provides resources and data focused on fire prevention strategies and safety standards. - UL Standards & Engagement

UL develops safety standards for fire protection equipment and systems, emphasizing compliance with the latest safety requirements.

By exploring these resources, fire departments can better understand the frameworks guiding fire safety practices and ensure that their designs meet essential safety requirements, ultimately leading to more efficient and effective fire response capabilities.

Ladder Accessibility and Design

Ladder accessibility is a critical component in the design of pumper fire trucks, significantly influencing both firefighter safety and operational efficiency during emergencies. Fire departments must prioritize a number of key considerations when it comes to the ladders that form a vital part of their firefighting arsenal.

Material Selection: The choice of ladder materials impacts overall functionality and safety. Common materials include:

- Aluminum: Lightweight and durable, aluminum ladders facilitate easier handling – a crucial factor for quick deployment. However, their conductivity necessitates caution around electrical hazards.

- Wood: Though heavier, wooden ladders offer non-conductive properties, making them safer in electrical situations. Proper maintenance and protection from the elements are necessary to ensure longevity.

- Fiberglass: Providing a balance of durability and safety, fiberglass ladders are resistant to electrical hazards but come at a higher cost.

Placement and Storage: Strategic placement is key for quick access during emergencies:

- External Ladder Racks: Mounting ladders externally allows for swift deployment but can expose them to wear and environmental damage, necessitating regular inspections and maintenance to mitigate risks.

- Internal Storage: While internal storage protects ladders from external damage, it may slow deployment times. Ensuring easy access without compromising safety should be a priority.

Proper ladder support is essential regardless of how ladders are stored to prevent deformation over time. Utilizing padded brackets and ensuring proper weight distribution can help maintain structural integrity.

Safety and Efficiency Best Practices: To enhance functionality further:

- Routine Inspections: Conducting regular inspections is vital to maintaining ladders in optimal working condition, thereby identifying potential issues before they escalate.

- Standardization: By standardizing ladder designs and placement across all vehicles in the fleet, fire departments can streamline training and response efforts.

- Training Programs: Regular training on ladder deployment and safe handling techniques for various configurations is essential to ensure firefighter readiness during real emergencies.

In summary, thoughtful consideration of ladder accessibility and design elements is paramount for enhancing the performance of pumper fire trucks, ultimately ensuring that firefighters can respond efficiently and safely in high-pressure situations.

Conclusion

In conclusion, the design of pumper fire trucks holds significant importance for operational efficiency and firefighter safety. Key features such as chassis and engine selection, water tank size, pump ratings, hosebed accessibility, and ladder design must be considered meticulously. Each aspect plays a vital role in enhancing response capabilities, ensuring that firefighters can act swiftly and effectively in emergencies.

For fire departments, prioritizing these elements during the design process is essential to meet both community demands and safety standards. As critical first responders, investing in properly designed apparatus can lead to better outcomes, ultimately saving lives and property when it matters most. Therefore, let us take these insights to heart and apply them in practice, fostering a culture of safety and efficiency in fire service operations.

Expert Insight

“In designing pumper fire trucks, every decision we make should be anchored in our tactical philosophy; it is about enhancing operational efficiency while ensuring the safety of our firefighters. Each aspect of the apparatus must cater to the demands of aggressive firefighting strategies, allowing us to put the fire out quickly and effectively.”

— James Curtis

This quote underscores the critical relationship between tactical philosophy and fire truck design, emphasizing that each design choice must enhance both efficiency and safety.