In the high-stakes world of firefighting, every second counts, making effective fire truck product support crucial for maximizing uptime. Fire trucks are not just vehicles; they are highly complex machines equipped with multiple functions essential for saving lives and protecting property. Understanding the intricacies of fire apparatus maintenance and repair is vital for any fire department committed to operational efficiency. That’s where a comprehensive support network comes in. With a suite of services ranging from preventative maintenance and technical support to mobile service vehicles ready for on-site assistance, fire truck manufacturers have developed extensive product support offerings. This robust approach ensures that fire departments can quickly and effectively address any issues that arise, thereby maintaining the readiness of their critical equipment.

Pierce Manufacturing, for instance, boasts the largest product support network in the market, ensuring that their fire trucks remain operational throughout their lifespan. However, regardless of the manufacturer, prioritizing effective product support is the key to achieving and sustaining maximum uptime for these indispensable vehicles.

Types of Fire Truck Support Services

Fire truck support services are essential for ensuring the reliability and readiness of fire apparatus. Here are the main types of support that contribute to minimizing downtime and maximizing operational efficiency:

- Preventive Maintenance

- Conduct regular inspections and servicing to identify potential issues before they escalate.

- Perform tasks such as oil changes, tire rotations, and brake checks following manufacturer guidelines.

- For instance, certain departments may schedule oil changes every 250-300 hours of vehicle operation.

- Corrective Maintenance

- Involves repairs made after issues arise, including replacing worn-out hoses and addressing pump failures.

- While necessary at times, a robust maintenance program aims to minimize its frequency.

- Technical Support

- Provides access to specialized technical expertise for diagnosing complex issues using diagnostic tools.

- Support from manufacturers and trained technicians ensures efficient repairs.

- Mobile Maintenance Services

- On-site maintenance and repairs significantly reduce transportation needs and downtime for fire apparatus.

- This approach optimizes availability during emergencies.

- Telematics and Fleet Management

- Real-time vehicle performance monitoring helps fire departments anticipate maintenance needs and plan repairs.

- This proactive strategy reduces unexpected downtime.

Impact on Uptime

Implementing comprehensive support enhances the uptime of fire apparatus by:

- Ensuring reliability.

- Minimizing unplanned downtime.

- Enabling cost savings.

- Ensuring operational efficiency.

Such strategies are paramount for keeping fire trucks in optimal condition, ensuring they are always ready for emergencies.

Importance of Fire Truck Product Support

Industry experts stress that comprehensive maintenance and product support are crucial for the uptime and reliability of fire trucks. Regular preventive maintenance can:

- Reduce apparatus downtime and service calls.

- Minimize breakdowns and mechanic overtime.

- Lead to safe and dependable performance, thereby serving as a compelling reminder of the value of effective support services.

Daily and weekly inspections are critical to assessing the condition of vital components, including:

- Fluid levels

- Tires

- Equipment

Experts recommend conducting monthly and quarterly checks focusing on systems like brakes and safety equipment to prevent malfunctions. Annual inspections can address major issues and ensure compliance with safety regulations.

A structured preventive maintenance program is essential for maximizing fire truck uptime. It should:

- Adhere to recommended service frequencies.

- Allow for customizable maintenance schedules.

A timely quote emphasizes this point: “By implementing these best practices, fire departments can significantly enhance the reliability and longevity of their fire trucks.”

A well-maintained fire truck is a safer vehicle for both passengers and the community. A proactive preventive maintenance program can be invaluable in legal scenarios, supporting risk management. Experts assert that this structured approach maximizes apparatus uptime and aligns with the mission of protecting lives and property.

By following these insights, fire departments can optimize their operations and better serve their communities. Product support remains an indispensable aspect of effective fire truck management.

| Feature | Pierce Manufacturing | Oshkosh Corporation |

|---|---|---|

| Service Types | Factory & Field Service, Warranty Support, Training | Field Service Support, Warranty Support |

| Technician Availability | Over 600 Factory-Trained Technicians | Over 130 Service Providers with Master Certified Technicians |

| Unique Support Offerings | Customized service training classes, Online Parts Catalog | Structured training programs, Snozzle HRET and Legacy Training |

Impact of Quick Response from Service Technicians

Timely service responses from trained technicians can significantly reduce downtime for fire trucks, an area of critical concern for fire departments committed to operational efficiency. In the firefighting industry, every second counts, and minimizing delays is vital to ensure that fire apparatus is always ready when emergencies arise.

Cost of Downtime

Studies have shown that unplanned truck downtime costs U.S. fleets an average of $760 per vehicle per day, leading to substantial financial losses, which total over $74 billion annually due to maintenance-related breakdowns. In contrast, fleets that adopt predictive maintenance strategies can achieve an impressive 97% uptime rate, emphasizing the value of proactive service interventions. When technicians respond quickly to maintenance and repair needs, fire trucks spend less time off the road and more time in action during critical situations.

Efficiency and Effectiveness

The introduction of real-time equipment monitoring has revolutionized fleet performance. Continuous health assessments enable fire departments to predict and identify failures before they occur, leading to a remarkable 65% reduction in unplanned downtime and annual savings of over $125,000 per machine. By ensuring that fire trucks are consistently operational, quick responses enhance the overall efficiency and effectiveness of fire departments, directly contributing to their mission of saving lives and protecting communities.

Industry Insights and Statistics

Feedback from U.S. fleet managers indicates that 68% observed a significant reduction in downtime after adopting preventive maintenance practices. Furthermore, in the field service sector, those utilizing advanced field service management software achieved a remarkable 32% improvement in response times, compared to companies reliant on manual processes. This underscores the critical impact that speedy technician responses have on equipment readiness and department performance.

In conclusion, the prompt response of service technicians plays a pivotal role in ensuring that fire trucks maintain their operational readiness, thus reinforcing the ability of fire departments to serve their communities effectively during emergencies.

“Thanks to Pierce Manufacturing, we have the utmost confidence in our fire truck’s performance. Their nationwide support network, with over 600 factory-trained technicians, ensures that no matter where we are, help is just a call away. The availability of 24/7 technical support and immediate parts delivery has made a significant difference in our operations. We truly appreciate their commitment to our needs, which kept our apparatus running at peak performance during emergencies!”

This testimonial highlights not only the effectiveness of Pierce’s product support services but also emphasizes customer trust and satisfaction in critical situations.

In conclusion, effective fire truck product support services are critical for ensuring that fire departments maximize the uptime and operational efficiency of their apparatus. By establishing structured maintenance programs that include preventive and corrective maintenance, technical support, and mobile services, fire departments can significantly enhance their overall performance and reliability.

Key Insights into Fire Truck Support:

- Regular Preventive Maintenance: Implementing routine inspections and services is not just a best practice, but a necessity. This can include actions as simple as daily checks and more comprehensive annual tests, which cumulatively work to prevent major issues and reduce downtime.

- The Role of Timely Technician Support: Quick response times from trained technicians minimizes the risk of extended downtime, directly impacting the operational readiness of fire apparatus. Studies have demonstrated a remarkable reduction in downtime and associated costs through effective support services.

- Adherence to Best Practices: Following established guidelines and using advanced fleet management tools ensure that fire departments can anticipate and address maintenance needs proactively.

Given these insights, fire departments must consider the importance of comprehensive product support offerings when purchasing fire apparatus. By investing in reliable support services, they can ensure that their fire trucks remain safe, efficient, and ready for action when emergencies strike.

Call to Action:

As you navigate the complexities of fire truck purchases, prioritize evaluations of product support networks and service offerings. Opt for manufacturers like Pierce Manufacturing, which not only provide top-notch vehicles but also robust support systems that keep your equipment operational in the most critical times. Don’t just invest in a fire truck – invest in its future performance and reliability!

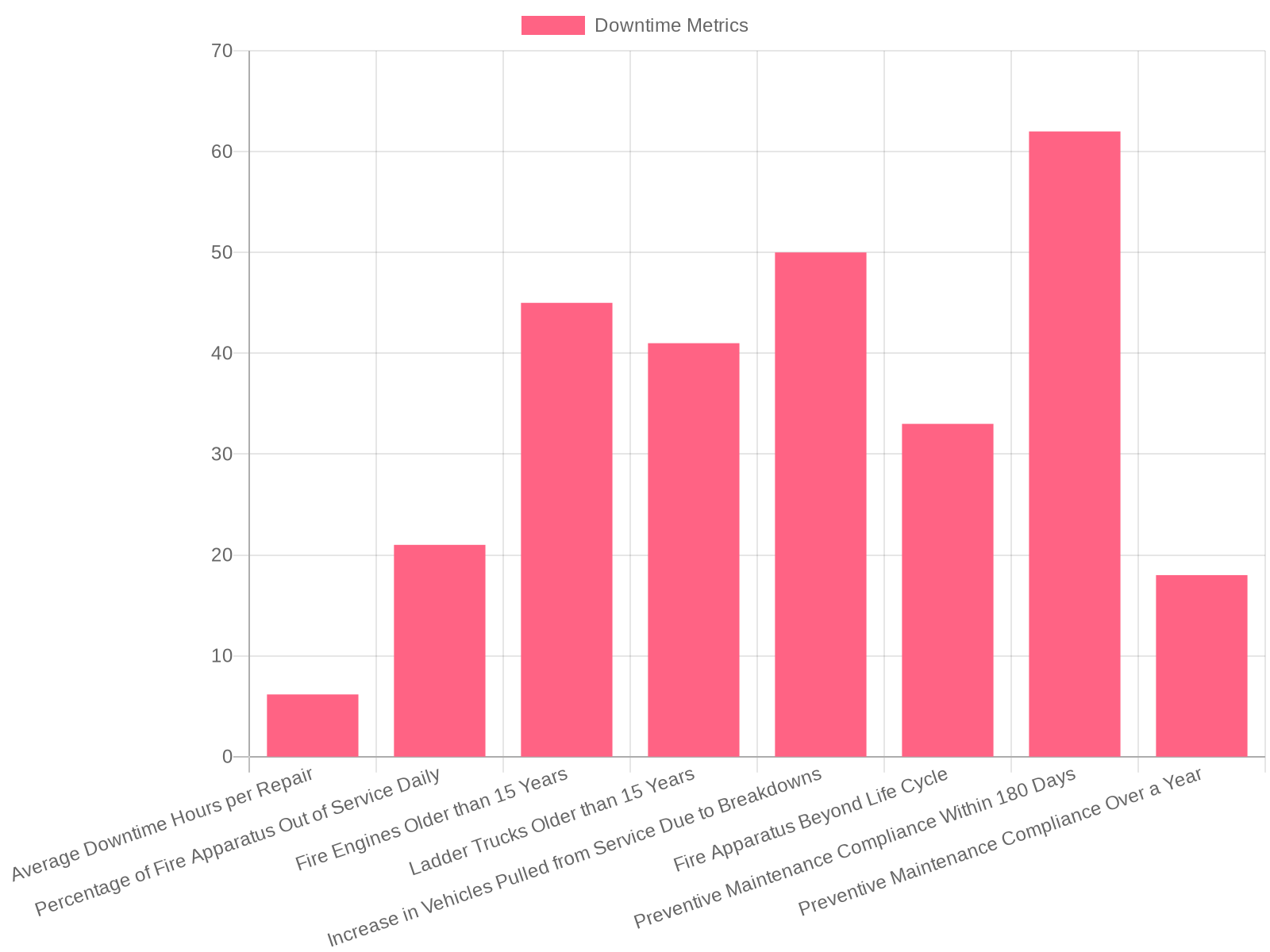

This graph illustrates key metrics related to fire truck downtime, highlighting the importance of product support and the impact of maintenance practices on reducing downtime.

| Metric | Data | Source |

|---|---|---|

| Average Downtime Hours per Repair (Atlanta Fire Department, 2020-2023) | 6.17 hours | Audit Report on Atlanta’s Fire Fleet Maintenance |

| Percentage of Fire Apparatus Out of Service Daily (Atlanta Fire Department, 2022-2023) | 21% (approximately 12 vehicles) | Audit Report on Atlanta’s Fire Fleet Maintenance |

| Fire Engines Older than 15 Years (Seattle Fire Department, 2024) | 45% | Seattle Fire Trucks Are Deteriorating Too Fast for Repairs |

| Ladder Trucks Older than 15 Years (Seattle Fire Department, 2024) | 41% | Seattle Fire Trucks Are Deteriorating Too Fast for Repairs |

| Increase in Vehicles Pulled from Service Due to Breakdowns (Seattle Fire Department, 2016-2024) | Over 50% | Seattle Fire Trucks Are Deteriorating Too Fast for Repairs |

| Fire Apparatus Beyond Life Cycle (Atlanta Fire Department, 2024) | One-third of vehicles | Audit Finds One-Third of Atlanta’s Fire Trucks Beyond Their Lifespan |

| Preventive Maintenance Compliance (Atlanta Fire Department, 2018-2023) | 62% within 180 days; 18% had no preventive maintenance in over a year | Audit Report on Atlanta’s Fire Fleet Maintenance |

| Impact of Aging Fleet on Maintenance Costs and Downtime | Increased maintenance costs and downtime in later years; more economical to replace trucks earlier | 2022 London Fire Master Plan |

Call to Action:

As you navigate the complexities of fire truck purchases, prioritize evaluations of product support networks and service offerings. Opt for manufacturers like Pierce Manufacturing, which not only provide top-notch vehicles but also robust support systems that keep your equipment operational in the most critical times. Don’t just invest in a fire truck – invest in its future performance and reliability!

To enhance your understanding of effective fire truck maintenance, consider visiting the following credible sources:

- Midwest Fire discusses important best practices for regular operation and pump maintenance.

- Fire Apparatus Magazine covers the significance of preventive maintenance programs.

- Toyne provides a comprehensive maintenance checklist focused on critical systems.

- Fenton Fire details what you need to know about electrical systems and overall maintenance strategies.

- Isuzu Vehicles emphasizes key maintenance aspects for optimal truck performance and reliability.

By educating yourself on these practices, you can effectively manage your fire truck operations, ensuring safety and readiness when it matters most!

In the high-stakes world of firefighting, every second counts, making effective fire truck maintenance crucial for maximizing uptime. Fire trucks are not just vehicles; they are highly complex machines equipped with multiple functions essential for saving lives and protecting property. Understanding the intricacies of fire apparatus maintenance and repair is vital for any fire department committed to operational efficiency. That’s where a comprehensive support network comes in. With a suite of services ranging from preventative maintenance and technical support to mobile service vehicles ready for on-site assistance, fire truck manufacturers have developed extensive product support offerings. This robust approach ensures that fire departments can quickly and effectively address any issues that arise, thereby maintaining the readiness of their critical equipment. Pierce Manufacturing, for instance, boasts the largest product support network in the market, ensuring that their fire trucks remain operational throughout their lifespan. However, regardless of the manufacturer, prioritizing effective product support is the key to achieving and sustaining maximum uptime for these indispensable vehicles.

Types of Fire Truck Support Services

Fire truck support services are essential for ensuring the reliability and readiness of fire apparatus. Here are the main types of support that contribute to minimizing downtime and maximizing operational efficiency:

-

Preventive Maintenance

- Conduct regular inspections and servicing to identify potential issues before they escalate.

- Perform tasks such as oil changes, tire rotations, and brake checks following manufacturer guidelines.

- For instance, certain departments may schedule oil changes every 250-300 hours of vehicle operation.

-

Corrective Maintenance

- Involves repairs made after issues arise, including replacing worn-out hoses and addressing pump failures.

- While necessary at times, a robust maintenance program aims to minimize its frequency.

-

Technical Support

- Provides access to specialized technical expertise for diagnosing complex issues using diagnostic tools.

- Support from manufacturers and trained technicians ensures efficient repairs.

-

Mobile Maintenance Services

- On-site maintenance and repairs significantly reduce transportation needs and downtime for fire apparatus.

- This approach optimizes availability during emergencies.

-

Telematics and Fleet Management

- Real-time vehicle performance monitoring helps fire departments anticipate maintenance needs and plan repairs.

- This proactive strategy reduces unexpected downtime.

Impact on Uptime

Implementing comprehensive support enhances the uptime of fire apparatus by:

- Ensuring reliability.

- Minimizing unplanned downtime.

- Enabling cost savings.

- Ensuring operational efficiency.

Such strategies are paramount for keeping fire trucks in optimal condition, ensuring they are always ready for emergencies.

Importance of Fire Truck Product Support

Industry experts stress that comprehensive maintenance and product support are crucial for the uptime and reliability of fire trucks. Regular preventive maintenance can:

- Reduce apparatus downtime and service calls.

- Minimize breakdowns and mechanic overtime.

- Lead to safe and dependable performance, thereby serving as a compelling reminder of the value of effective support services.

Daily and weekly inspections are critical to assessing the condition of vital components, including:

- Fluid levels

- Tires

- Equipment

Experts recommend conducting monthly and quarterly checks focusing on systems like brakes and safety equipment to prevent malfunctions. Annual inspections can address major issues and ensure compliance with safety regulations.

A structured preventive maintenance program is essential for maximizing fire truck uptime. It should:

- Adhere to recommended service frequencies.

- Allow for customizable maintenance schedules.

A timely quote emphasizes this point: “By implementing these best practices, fire departments can significantly enhance the reliability and longevity of their fire trucks.”

A well-maintained fire truck is a safer vehicle for both passengers and the community. A proactive preventive maintenance program can be invaluable in legal scenarios, supporting risk management. Experts assert that this structured approach maximizes apparatus uptime and aligns with the mission of protecting lives and property.

By following these insights, fire departments can optimize their operations and better serve their communities. Product support remains an indispensable aspect of effective fire truck management.

Impact of Quick Response from Service Technicians

Timely service responses from trained technicians can significantly reduce downtime for fire trucks, an area of critical concern for fire departments committed to operational efficiency. In the firefighting industry, every second counts, and minimizing delays is vital to ensure that fire apparatus is always ready when emergencies arise.

Cost of Downtime

Studies have shown that unplanned truck downtime costs U.S. fleets an average of $760 per vehicle per day, leading to substantial financial losses, which total over $74 billion annually due to maintenance-related breakdowns. In contrast, fleets that adopt predictive maintenance strategies can achieve an impressive 97% uptime rate, emphasizing the value of proactive service interventions. When technicians respond quickly to maintenance and repair needs, fire trucks spend less time off the road and more time in action during critical situations.

Efficiency and Effectiveness

The introduction of real-time equipment monitoring has revolutionized fleet performance. Continuous health assessments enable fire departments to predict and identify failures before they occur, leading to a remarkable 65% reduction in unplanned downtime and annual savings of over $125,000 per machine. By ensuring that fire trucks are consistently operational, quick responses enhance the overall efficiency and effectiveness of fire departments, directly contributing to their mission of saving lives and protecting communities.

Industry Insights and Statistics

Feedback from U.S. fleet managers indicates that 68% observed a significant reduction in downtime after adopting preventive maintenance practices. Furthermore, in the field service sector, those utilizing advanced field service management software achieved a remarkable 32% improvement in response times, compared to companies reliant on manual processes. This underscores the critical impact that speedy technician responses have on equipment readiness and department performance.

In conclusion, the prompt response of service technicians plays a pivotal role in ensuring that fire trucks maintain their operational readiness, thus reinforcing the ability of fire departments to serve their communities effectively during emergencies.

Call to Action

As you navigate the complexities of fire truck purchases, prioritize evaluations of product support networks and service offerings. Opt for manufacturers like Pierce Manufacturing, which not only provide top-notch vehicles but also robust support systems that keep your equipment operational in the most critical times. Don’t just invest in a fire truck – invest in its future performance and reliability!

To enhance your understanding of effective fire truck maintenance, consider visiting the following credible sources:

- Midwest Fire discusses important best practices for regular operation and pump maintenance.

- Fire Apparatus Magazine covers the significance of preventive maintenance programs.

- Toyne provides a comprehensive maintenance checklist focused on critical systems.

- Fenton Fire details what you need to know about electrical systems and overall maintenance strategies.

- Isuzu Vehicles emphasizes key maintenance aspects for optimal truck performance and reliability.

By educating yourself on these practices, you can effectively manage your fire truck operations, ensuring safety and readiness when it matters most!