The lift truck services sector is an unsung hero in logistics, providing critical support for the transportation and handling of goods. This article dives deep into the importance of one lift truck services for long-haul truck drivers, trucking companies, fleet managers, and aspiring drivers. Each chapter will illuminate key aspects, from an overview of market growth to maintenance, training, and future innovations, helping you navigate the dynamic landscape and optimize your operations effectively.

One Lift Truck Services: Integrating Equipment, Maintenance, and Training for Seamless Material Movement

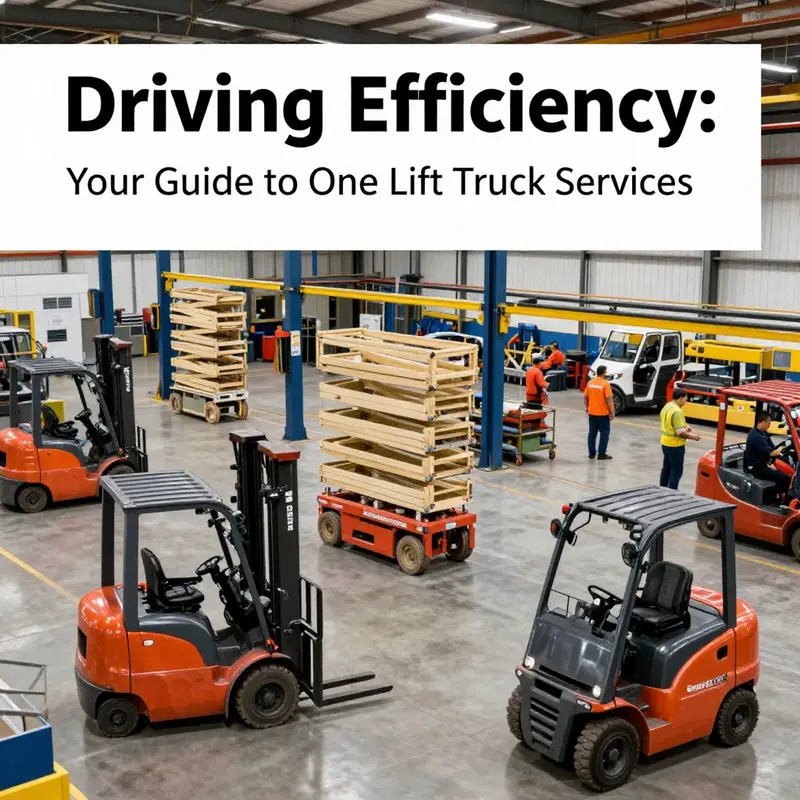

The landscape of modern logistics hinges on the reliable, efficient movement of goods through complex networks of warehouses, factories, and service yards. A one lift truck services approach treats material handling as an integrated system rather than a bundle of disparate tasks. It recognizes that equipment supply, routine maintenance, emergency repairs, rental options, and operator training are not isolated functions but interdependent pillars that determine uptime, safety, and overall productivity. When a single provider orchestrates these elements, the result is a smoother flow of materials, fewer failed lifts, and shorter cycle times. This integrated mindset mirrors the broader shift in the industry toward holistic fleet solutions, where data, technology, and human skill combine to unlock continuous operation in environments that demand near-perfect reliability. The market dynamics behind this shift are underscored by robust growth in lift truck services around the world. As industries expand—especially e-commerce, automotive, construction, and retail—the need for dependable handling, rigorous safety standards, and rapid service responses becomes more pronounced. The market commentary from industry analyses points to a healthy expansion: a strong baseline of demand for forklift-related services alongside the rise of safer, more efficient, and more autonomous equipment. This combination drives not only more units in operation but also a deeper dependence on preventive maintenance, remote diagnostics, and smarter fleet management programs. The overarching trajectory is clear: facilities seek partners capable of delivering an end-to-end solution rather than piecemeal enhancements to their material-handling capability. A one stop shop for lift truck services becomes a strategic differentiator, enabling operators to minimize downtime, optimize asset utilization, and allocate capital more efficiently across the lifecycle of their fleets. Within this framework, the customer experiences a virtuous circle where ongoing maintenance reduces the frequency of costly breakdowns, predictive analytics flag potential failures before they interrupt production, and operator training translates into safer, more productive daily performance. This convergence of equipment, service, and knowledge is what sustains uptime during peak seasons, onboarding phases for new facilities, and periods of rapid volume growth. The value proposition also extends to the flexibility of choices. A single provider can offer a spectrum of engagement models—from outright equipment sale to long-term rental, with scalable service plans that align with demand fluctuations. For many operations, renting or leasing lift trucks along with a comprehensive preventive maintenance program provides a lower barrier to scale, while still ensuring compliance with safety and regulatory standards. The critical insight is that a one stop service model does more than keep machines running; it aligns the entire asset ecosystem with the business’s operational rhythms. It enables more accurate budgeting, clearer performance metrics, and faster response times when issues arise. In practice, this means a provider that can deliver not only the right equipment for a given indoor or outdoor environment but also the right maintenance cadence, spare parts availability, and operator training path. When a facility restructures its maintenance plan around a unified service framework, it experiences fewer last-minute service calls, more predictable maintenance windows, and a clearer view of total cost of ownership. The integration extends beyond mechanical care to include the digital layer. Modern lift truck services increasingly incorporate telematics, remote diagnostics, and data-driven monitoring of utilization, battery health, and load profiles. Telematics feeds maintenance scheduling, creates usage transparency for fleet managers, and supports energy optimization by recommending charging windows and battery cycling practices. Predictive maintenance becomes less about reacting to worn parts and more about anticipating wear patterns, thereby extending component life and reducing the risk of unplanned downtime. Operator training sits at the heart of this ecosystem as both a compliance mechanism and a performance lever. Training programs that accompany equipment provisioning reinforce safe operating practices, improve lift efficiency, and reduce the likelihood of accidents or product damage. When training is embedded within the service package, it travels with the equipment lifecycle, from initial handover to ongoing refreshers aligned with evolving technologies and regulatory updates. A well-structured training module can be delivered in person or through digital platforms, with competency checks that verify skill retention across different operators and shifts. In this sense, the one lift truck services model becomes a dynamic, living system rather than a static set of services. It is designed to adapt as the customer’s operations scale, as automation and electrification reshape fault tolerance and energy use, and as safety expectations continue to escalate. The benefits of this approach show up in several tangible ways. First, uptime improves because preventive maintenance plans are tightly coupled with real-world usage patterns. When a technician understands not just the machine but the context in which it operates, service interventions can be scheduled during natural downtime or low-volume periods, minimizing disruption. Second, safety compliance becomes more robust because operator training is synchronized with the specific equipment and its typical tasks. Third, the lifecycle cost of ownership declines as spare parts, service labor, and energy consumption are coordinated through a single vendor’s program. Even the occasional emergency repair—a scenario no operation can fully avoid—benefits from a unified response. A one stop provider can dispatch trained technicians who understand the asset family, access the necessary parts, and implement temporary containment measures to keep operations moving. The broader market signals support this model. In addition to the expanding forklift-related services market, the industry is increasingly embracing equipment that can operate safely in varying conditions, including automated and electric powertrains. These technologies bring lower emissions, quieter operation, and the potential for extended duty cycles, though they also introduce new maintenance profiles and charging infrastructure requirements. As a result, service providers must expand their capabilities to include energy management, battery health monitoring, and software updates for control systems. The synergy of equipment, care, and knowledge becomes especially meaningful in complex environments such as multi-shift warehouses, cold-storage facilities, or high-volume distribution centers where small inefficiencies compound into meaningful losses over time. In these settings, a provider that delivers integrated solutions—equipment, preventive care, rapid repairs, flexible rental terms, and certified operator training—helps clients avoid the friction that slows throughput. It also supports risk management, ensuring that fleets remain compliant with evolving safety standards while operators maintain high levels of proficiency. The practical implications extend to the shop floor. A one lift truck services approach informs how facilities plan site readiness, including floor quality, traffic patterns, and charging or refueling zones. It guides decisions about whether a given space should prioritize open floor areas for maneuverability or dedicated lanes for high-volume throughput. It also shapes how maintenance bays are organized, ensuring that spare parts, diagnostic tools, and skilled technicians are aligned with the facility’s operating rhythms. When maintenance becomes a planned activity rather than a reaction to failure, operators observe fewer interruptions, and managers gain a clearer forecast of capital replacement timelines. The narrative of integrated lift truck services is not a theoretical exercise but a practical, actionable strategy for sustaining throughput in modern supply chains. It emphasizes that uptime is not simply a function of rugged machines; it is the product of a carefully choreographed relationship among the equipment, the people who operate it, and the processes that keep it running. For organizations seeking to adopt this approach, the path is less about selecting a new brand of forklift and more about choosing a partner that can deliver the entire lifecycle in a synchronized package. The emphasis shifts toward collaboration, data-driven decision-making, and continuous improvement. The path forward is illuminated by the combination of smart controls, automation, and energy-efficient design, all of which are reshaping how lift trucks are used and cared for. As operations grow more complex, the value of a unified service model becomes more apparent: fewer interruptions, safer workplaces, and a measurable uplift in productivity. To readers seeking practical guidance, consider reviewing maintenance and training resources like fire-truck-maintenance-training-importance for insights on how formalized upkeep and structured operator education underpin reliable service programs. For a broader market perspective and future trajectory, consult industry analyses that track the forklift market’s expansion and how it informs service design and investment decisions. The evidence points to a future in which lift truck services evolve into a true ecosystem—where equipment, support, and knowledge together drive resilience, efficiency, and sustainable growth across diverse industries. As automation, remote diagnostics, and telematics mature, the one stop service model will likely become the standard bearer for material handling excellence, turning uptime from a goal into a predictable, repeatable outcome. For researchers and practitioners alike, the takeaway is that successful lift truck programs no longer depend on one-off repairs or ad hoc training; they depend on integrated, end-to-end service designs that treat the fleet as a single, living system. External reference: For a detailed trajectory of the forklift market, see Grand View Research’s Market Size, Share & Growth Analysis. https://www.grandviewresearch.com/industry-analysis/forklift-truck-market

One Lift, Many Safeguards: Integrated Maintenance and Safety in Modern Lift Truck Services

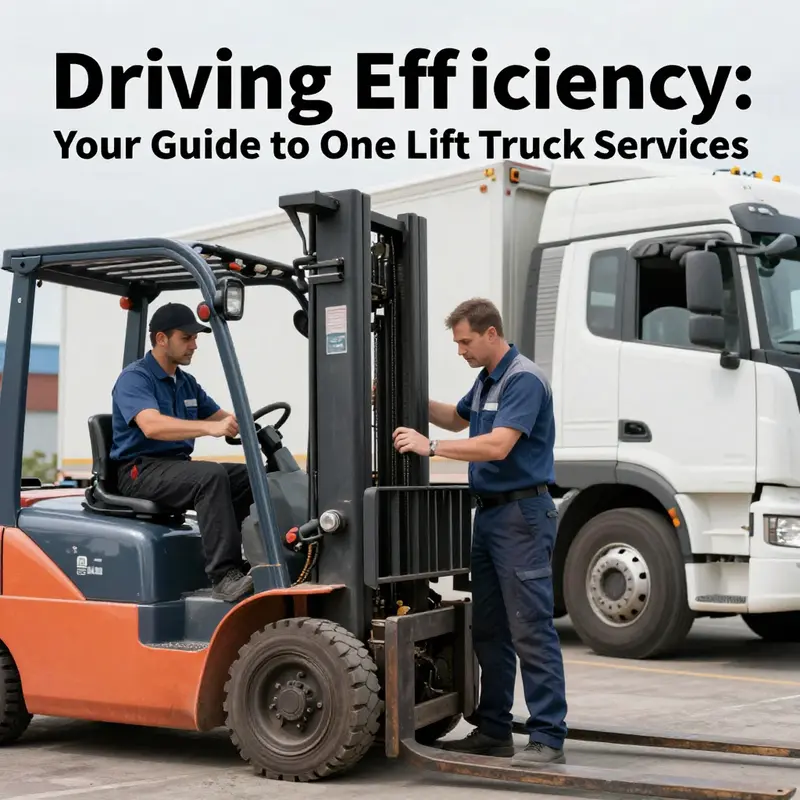

Maintenance and safety are the core of reliable lift truck operation. A unified service model combines preventative maintenance, rapid repairs, fleet management, and operator training into a single, accountable system. In modern warehouses, uptime matters as much as safety, and a one-stop approach reduces fragmentation, shortens response times, and improves total cost of ownership. Through regular inspections, data-informed maintenance, and proactive safety training, facilities can expect fewer breakdowns, fewer injuries, and more predictable throughput. Technology such as telematics, remote diagnostics, and lifecycle management supports proactive planning while preserving a human-centered safety culture. This chapter outlines how integrated services translate into measurable outcomes, from improved equipment utilization to safer work practices, and sets the stage for practical steps to implement a true one-stop lift truck service. External resources and safety guidelines provide benchmarks for continuous improvement.

A One Lift Truck Services: Training and Compliance Reimagined for Safer, Smarter Warehouses

In modern warehouses and distribution centers, the lift truck is more than a piece of equipment; it is a critical lifeline that moves components, goods, and possibilities through the entire supply chain. Yet with great capability comes great responsibility. A focused program of training and compliance, anchored by a single, reliable lift truck services partner, transforms a fleet from a collection of machines into a systematic, safe, and productive ecosystem. A one-stop approach to training and compliance addresses not only the mechanics of operation but the culture that underpins every safe lift, every careful turn, and every practiced procedure. When organizations align their people, their processes, and their equipment around a shared standard of safety, they gain more than compliance—they gain resilience and predictability in an environment where margins of error are costly. This chapter explores how training and compliance, embedded within a comprehensive lift truck services strategy, can reduce accidents, extend equipment life, and elevate warehouse performance without sacrificing speed or flexibility.

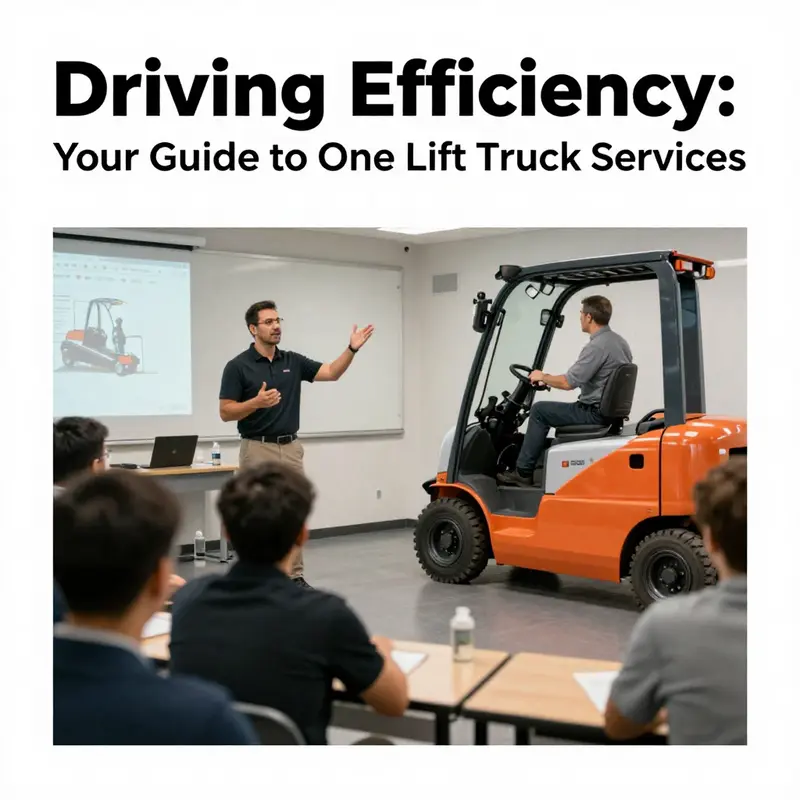

A foundational truth frames the entire discussion: continuous, well-designed training is the most effective means to reduce incidents and boost operational efficiency. It is not a one-time event but a living program that adapts to changing conditions—new equipment, new processes, new products, and new safety regulations. By adopting a competency-based approach, a warehouse shifts from counting training hours to validating real-world capability. Operators progress through a cascade of learning experiences—classroom foundations that describe the physics of load handling and stability, simulations that model real-world hazards, and hands-on practice under vigilant supervision. The goal is not only to meet regulatory requirements but to create workers who can anticipate risk, communicate clearly, and recover swiftly from the unexpected. In practice, this means standardizing the core curriculum while allowing room for role-specific scenarios. For example, a general operator track may emphasize basic vehicle controls, load handling, and pedestrian awareness, while a technician track focuses on maintenance indicators, fault diagnosis, and safe repair procedures. The continuum ensures that every operator can demonstrate proficiency across the most common work scenarios, from high-traffic pallet movement to confined-space navigation and uneven surfaces.

Regulatory compliance anchors the program in a shared framework that both protects workers and protects the business. Across many jurisdictions, powered industrial trucks require formal operator training, hands-on assessment, and periodic refresher sessions. These requirements are not mere box-ticking rituals; they are evidence of a proactive safety culture. A one-lift-truck services provider, oriented around safety, integrates regulatory considerations into daily routines. Before an operator touches a forklift, documented training records verify competency, and ongoing evaluation confirms that proficiency remains current as procedures evolve. This systematic approach reduces the risk of over-reliance on a single veteran operator and diminishes the likelihood that fatigue, complacency, or poorly understood procedures will lead to injuries. The documentation itself becomes a signal—a visible, auditable trail that demonstrates accountability throughout the organization. In practice, this translates into clear records of initial certification, periodic requalification, and targeted retraining after any incident, near-miss, or equipment change. When machine operators understand the reasons behind rules—stability limits, speed controls, and path selection—they are more likely to follow them consistently, even under pressure.

The integration of training with maintenance and fleet management creates a virtuous cycle of safety and efficiency. Skilled operators are better at recognizing equipment faults early, reporting issues promptly, and using tools correctly that preserve machine integrity. Likewise, maintenance teams benefit from operators who understand the life cycle of components, the consequences of improper use, and the importance of timely inspections. A holistic program, therefore, intertwines instructional content with field practices: daily pre-shift checks, routine lubrication schedules, battery handling and charging best practices for electric trucks, and safe load-handling techniques. When maintenance becomes a shared responsibility—rooted in training and reinforced by data from telematics or onboard diagnostics—unexpected downtime diminishes and uptime climbs. The result is a fleet that remains reliable under varying workloads and shifts, with fewer breakdowns and faster repair turnarounds. In this environment, the cost of training is offset by longer equipment life, lower repair costs, and steadier productivity.

Technology reshapes what good training looks like and how it is delivered. Modern lift trucks, including electric and automated variants, introduce new safety considerations and operational layers. Training programs must evolve to cover battery handling hazards, charging infrastructure, and safe interaction with automated systems or semi-automated workflows. Operators need to understand energy management, visibility around sensor-based safety features, and appropriate responses when autonomous or semi-autonomous functions encounter anomalies. For managers, technology brings new tools for performance monitoring and risk assessment. Telematics can illustrate real-time operator behavior, route efficiency, and equipment health, enabling targeted coaching rather than broad, time-based retraining. This data-driven approach helps identify gaps—whether an operator consistently approaches a corner at excessive speed or a team member neglects pre-shift checks—and then closes them with precisely crafted, context-rich training modules. When learning is anchored to actual job performance, it becomes relevant, memorable, and more likely to influence long-term behavior.

A learning culture that prioritizes safety extends beyond the classroom. It becomes visible in every interaction on the floor—how supervisors conduct briefings, how near-miss reports are discussed, and how feedback is given and received. The most effective training programs foster psychological safety, inviting operators to share mistakes without fear of punishment, so that root causes can be explored and mitigated. They also recognize the social dynamics of the workplace: familiarity with pedestrians, visibility challenges in narrow aisles, and the legitimate need for efficient, timely material movement. In such environments, coaching is continuous and collaborative. A skilled supervisor or trainer would not merely correct an error; they would explain the underlying principle, demonstrate a safer approach, and provide opportunities for deliberate practice until the new method becomes second nature. This approach reduces the likelihood that a single error escalates into injury or equipment damage, transforming risk management from a reactive process into a proactive discipline.

The measurable benefits of a robust training and compliance program extend beyond compliance metrics. When operators are confident in their abilities, they move with greater purpose and accuracy, which translates into fewer dropped loads, smoother stacking, and faster cycle times without compromising safety. The efficiency gains compound as trained teams share best practices, standardize handoffs between shifts, and maintain consistent operating rhythms. A well-designed program also supports maintenance and procurement strategies. For instance, operators who understand load limits and stability principles are less likely to engage in risky maneuvers that strain equipment or create hazardous conditions. They can also provide valuable feedback to maintenance teams about unusual noises, vibrations, or handling quirks, accelerating diagnostics and ensuring that issues are addressed before they progress. In turn, maintenance teams that see themselves as partners in safety—not gatekeepers of compliance—can tailor interventions to the observed realities of the worksite, rather than to abstract guidelines.

From a strategic perspective, a one-lift-truck services provider that centralizes training and compliance can deliver economies of scale without sacrificing customization. A core, standardized curriculum provides a reliable foundation across multiple sites, ensuring consistency in safety language, procedures, and expectations. At the same time, the program can accommodate site-specific hazards, such as volume spikes, material variations, or distinct physical layouts. The balance between standardization and customization is the key to scalability: organizations gain predictable safety outcomes and a replicable training model, while locations retain the flexibility to address unique challenges. Moreover, documentation and certification records, maintained centrally, simplify audits and due-diligence processes, reducing administrative friction and ensuring that safety commitments are visible to stakeholders, insurers, and regulators alike.

Looking to the horizon, the future of training and compliance in lift truck services is likely to be characterized by modular, bite-sized learning that respects the realities of shift work and the attention demands of busy warehouses. Micro-learning bursts delivered through mobile devices can reinforce key principles at moments of need—before a shift starts, during a lull in activity, or after a near-miss incident. Virtual simulations and augmented reality scenarios may offer safe environments to practice high-risk tasks, such as reversing in crowded aisles or stacking at height, without interrupting production. Yet no technology substitutes the value of skilled, empathetic instruction and practical, on-site coaching. The strongest programs meld human expertise with digital tools, enabling operators to internalize safe habits while providing managers with actionable insights into performance, risk, and opportunities for improvement.

The insights drawn from industry best practices reinforce a simple, enduring message: training and compliance are investments in people as much as machines. In a well-run lift truck operation, safety is not a separate program; it is the operating system that underpins every decision, every load, and every route. When organizations commit to continuous learning, rigorous yet fair assessments, and transparent accountability, they build warehouses that are not only compliant but resilient—capable of meeting rising demand, adapting to new equipment, and sustaining high levels of service under pressure. The evidence is clear: ongoing training reduces accidents, sharpens efficiency, and protects both workers and assets. The challenge, then, is to design programs that are purposeful, scalable, and alive—programs that empower operators to excel, supervisors to lead with clarity, and maintenance teams to partner with safety at the core of every action.

External resource: For a comprehensive view of training and compliance resources in lift truck operations, see https://www.aoneforklift.com/training-and-compliance

One Lift Truck Services at the Forefront: Navigating the Tech-Driven Evolution of Material Handling

The lift truck services landscape stands at a turning point where reliability, efficiency, and safety converge to redefine how warehouses, manufacturing floors, and distribution hubs move the goods that power modern economies. A One Lift Truck Services sits squarely in the middle of this transformation, offering more than routine maintenance or on-demand repairs. It represents a model of service that couples technical depth with strategic foresight—an approach aligned with a market that, according to recent analyses, is estimated at USD 76.31 billion in 2026 and projected to reach USD 93.61 billion by 2031, growing at a compound annual rate of about 4.17%. Those numbers aren’t merely abstractions; they signal a sustained demand for equipment, expertise, and enduring partnerships that keep material handling seamless even as warehouses grow larger, more automated, and more data-driven. In this context, the role of a lift truck service provider expands from the shop floor to the broader operational strategy, where every maintenance decision, software update, and operator training choice ripples through productivity, safety, and total cost of ownership.

Technology-driven advances have accelerated this shift in ways that are tangible on every shift. Electric powertrains, for instance, bring energy efficiency to the fore and align with sustainability targets that are increasingly non-negotiable in warehouse design. The benefits extend beyond reduced emissions. Electric systems tend to deliver smoother operation, lower noise levels, and better torque characteristics under load, all of which influence indoor working conditions and maintenance schedules. A service partner like One Lift Truck Services is positioned to help warehouses realize these gains by not only installing and calibrating electrified powertrains but also by coaching facilities on optimal charging strategies, energy management, and lifecycle planning. The result is a cleaner, quieter, more cost-effective operating profile that can directly impact throughput and worker satisfaction.

Another pillar of the current evolution is telematics. Real-time data streams from lift trucks provide visibility into utilization patterns, health indicators, and potential faults before they translate into downtime. Telematics-driven maintenance—predictive rather than reactive—lets fleets stay in a state of readiness and reduces the costly surprises that disrupt a shift. For a service provider, this means adopting a proactive posture: constant monitoring, remote diagnostics, and rapid dispatch once a predictive alert is triggered. It also requires a robust data workflow, where insights are translated into concrete maintenance actions, spare parts planning, and replacement scheduling that minimizes production disruption. In practice, this transforms the service relationship from a break-fix model into a continuous, data-informed partnership that optimizes equipment uptime and operator productivity. Operators benefit too, gaining access to performance feedback and safety guidance that help them work smarter as well as safer.

Automation and semi-automation are reshaping what a lift truck can contribute to a warehouse’s value chain. Automated guided vehicles (AGVs) and driverless variants reduce human error, improve repeatability, and raise the baseline throughput of a facility. Yet automation does not render skilled technicians obsolete; it expands the technician’s remit. Calibration of sensors, software updates, integration with warehouse control systems, and ongoing safety validations require deep competence and disciplined change management. A One Lift Truck Services team gains a broader capability set by embracing these technologies, while remaining firmly grounded in the core competencies that have long defined professional maintenance: reliability testing, fault-root-cause analysis, and meticulous documentation. In practice, automation-enabled environments demand services that can offer modular, upgradeable solutions and a clear road map for scaling as the warehouse grows or shifts its product mix.

The human element remains central amid all digital advancement. Modern lift trucks incorporate enhanced operator ergonomics and safety features—sensors that detect proximity to pedestrians, collision avoidance systems, and intuitive control layouts that reduce fatigue and error. As these systems become more sophisticated, the need for rigorous operator training becomes more pronounced, not merely as a compliance exercise but as a core productivity input. Training programs need to be continuous, scenario-based, and aligned with the specific tasks of each facility. They should cover not only how to operate the equipment efficiently but also how to respond to predictive maintenance alerts, how to conduct basic troubleshooting, and how to engage with telematics dashboards during daily shifts. A well-designed training approach—blended with hands-on practice and digital coaching—helps operators internalize safety behaviors and leverage the equipment’s capabilities to their fullest.

Behind these capabilities lies a service model that extends beyond maintenance to deliver integrated solutions. Preventive maintenance programs, emergency repair services, fleet management, and operator training form a cohesive system that reduces downtime, extends asset life, and accelerates decision-making. This is where a partner like One Lift Truck Services proves its value: by coordinating service activity to match a facility’s production calendar, by maintaining a transparent parts supply, and by offering access to remote diagnostics that flag issues before they disrupt the line. The result is a smoother operation where fleet health is visible, trends are understood, and teams can prioritize investments with confidence. In environments that blend high inventory velocity with complex handling needs, such a synchronized approach to service can translate into meaningful gains in throughput and reliability.

As the market continues to mature, the conversation shifts toward total cost of ownership and risk management. Predictive maintenance helps reduce unexpected downtime and extends the life of hydraulic systems, chains, and powertrains, while telematics enables more precise labor planning and utilization metrics. The ability to forecast parts consumption and schedule downtime windows around production peaks lowers carrying costs and minimizes the risk of stockouts on critical components. In parallel, cyber risk management becomes a necessary consideration as fleets grow more connected. Securing maintenance software, protecting fleet data, and enforcing proper access controls are no longer ancillary concerns; they are integral to safeguarding uptime and ensuring compliance with safety and industry standards.

In this evolving landscape, an emphasis on ergonomics and safety remains foundational. Modern lift trucks equip operators with better visibility, adaptive control interfaces, and feedback mechanisms that guide routine checks and line-side maintenance. The human and machine elements must work in concert, with technicians translating sensor data and firmware updates into actionable improvements on the floor. A One Lift Truck Services approach recognizes that every facility has unique workflows, product mixes, and throughput targets. Rather than offering one-size-fits-all fixes, the company tailors maintenance windows, training curricula, and telematics configurations to the facility’s operating rhythm. This bespoke, systems-thinking mindset is what enables a service partner to help a warehouse scale its operations without sacrificing safety or reliability.

As facilities increasingly embrace a broader set of capabilities—energy efficiency, real-time visibility, automation, and advanced safety—the service model itself becomes a competitive differentiator. The best providers anticipate needs, align with the facility’s production plan, and translate technology investments into tangible operational benefits. The continuity of service matters just as much as the service itself. This means proactive spare parts planning, rapid dispatch, clear escalation paths, and transparent performance metrics that demonstrate how uptime improves over time. In practical terms, warehouses gain from a predictable maintenance cadence, reduced variability in machine performance, and a culture of proactive problem-solving that elevates the role of the technician to strategic partner for the operation. The upshot is a more resilient, responsive, and productive material-handling system that can adapt to shifting demand, evolving product flows, and safety expectations without breaking stride.

For those exploring the practicalities of applying these innovations, hands-on learning remains essential. Organizations often blend structured, classroom-style training with on-the-floor coaching and digital simulations to reinforce safe and efficient operation. Hands-on experiences with maintenance workflows—ranging from simple inspections to complex diagnostic routines—help teams translate abstract tech trends into reliable shop floor results. Illustratively, organizations often complement lift-truck maintenance education with specialized training resources such as fire-truck-maintenance-service-training, which emphasizes hands-on practice and safety-first fundamentals that are broadly applicable to heavy equipment maintenance. The goal is not to mimic a particular vehicle but to cultivate the judgment, discipline, and responsiveness that keep critical assets performing when their value and uptime truly matter. This is the kind of integrated, capability-building approach that underpins sustained improvements in uptime, safety, and throughput across industries.

The journey forward for One Lift Truck Services and its peers is not merely about adopting the newest gadget or software feature. It is about delivering a cohesive, adaptive ecosystem that aligns equipment health with production goals, energy strategies, and safety commitments. It is about enabling facilities to forecast needs, manage risk, and continuously improve the way material moves through the operation. It is about building partnerships that endure as technology evolves, markets shift, and the demands of the supply chain become more complex. In this sense, the lift truck service for the modern era is as much about strategy as it is about service calls. It is about turning uptime into a strategic advantage and letting people, processes, and machines work together with clarity and purpose. As the industry marches forward, the most successful providers will be those who blend technical mastery with practical judgment, and who remember that every innovation ultimately serves the people who operate, maintain, and rely on these essential industrial tools.

External resource for broader context: Material Handling Industry (MHI) website.

One Lift Truck Services: Economic Engine, Future-Ready Fleet, and the Pulse of Modern Logistics

In the echoing aisles of modern warehouses, the lift truck is more than a machine; it is the quiet, tireless engine that keeps supply chains breathing and customers satisfied. The narrative around lift truck services has long centered on uptime, safety, and the smooth cadence of daily operations. Yet beneath these practical concerns lies a broader truth: the sector’s economic footprint and its evolving capabilities are shaping the efficiency and resilience of national economies. Recent analyses place the lift truck industry squarely in the mainstream of economic metrics. In the United States, the sector contributed more than $25 billion to GDP and supported over 200,000 jobs. That figure, stated in a June 2026 briefing, reframes material handling from a backroom function to a strategic driver of productivity and jobs growth. When leadership at the helm of major manufacturers speaks of the sector’s reliability, it is not merely praise for equipment—it is an acknowledgment of how integral lift trucks are to the cadence of manufacturing, warehousing, and distribution networks that feed both consumer markets and industrial supply chains. As Brett Wood, president and CEO of Toyota Material Handling North America and chairman of the Industrial Truck Association, puts it, forklifts have been lifting America’s economy for over a century. The data, in his words, quantify the industry’s contributions to the broader economy. That statement is not just about the past; it is a roadmap for how current and future service models must operate to sustain and grow this essential function. The numbers also reflect a larger market story: the global lift truck fleet is expanding, and with it, the demand for comprehensive services that go beyond the sale of equipment. The market size for forklift trucks was estimated at $76.31 billion in 2026 and is projected to reach $93.61 billion by 2031, a compound annual growth rate around 4.17%. That trajectory is not incidental. It mirrors the expanding footprint of e-commerce, manufacturing resourcing, automotive and retail logistics, and the increasing complexity of warehouses that rely on precise, rapid, and safe material movement. In this context, a one-stop lift truck services provider exists not only to keep machines running but to synchronize people, devices, and data into an intelligent, safety-conscious system. The core service mix—preventive maintenance, emergency repair, fleet management, and operator training—maps directly onto the continuum of value that modern operations demand. Preventive maintenance programs anticipate failures before they disrupt flow, reducing unplanned downtime and extending the life of hydraulic systems, mast assemblies, battery fleets, and drivetrain components. Emergency repair services counteract the unpredictable events that can halt a line or a cross-docking operation, restoring productivity faster and preserving customer service levels. Fleet management solutions, often embedded with telematics, give managers visibility into utilization patterns, asset location, battery health, and charging cycles—data that inform decisions about leasing versus owning, replacement timing, and optimal truck mix for a given workflow. And operator training anchors safety and efficiency in every shift, reinforcing correct operating practices and reducing the likelihood of incidents that can derail operations or lead to costly insurance claims. Together, these services create a cohesive ecosystem where equipment, people, and process are mutually reinforcing. They are the scaffolding on which modern warehouses stand, enabling lean practices such as just-in-time inventory, cross-docking, and rapid order fulfillment. The economic impact of this ecosystem goes beyond the cash register, threading through productivity metrics, employment quality, and the ability of firms to scale operations in response to demand surges. The industry’s growth also reflects advances in technology that are redefining how lift trucks are used and maintained. Electric and hydrogen-powered forklifts are moving to the fore as companies pursue lower emissions, quieter operation, and longer-term cost savings in energy. These powertrains align with broader sustainability goals and often dovetail with strategies that reduce total cost of ownership for a fleet. With electrification and fuel-cell solutions, maintenance practices shift toward battery health monitoring, charging infrastructure management, and cleaner energy procurement. Also transforming the landscape are automation and data-enabled management systems. Autonomous guided vehicles (AGVs) and semi-autonomous systems are not replacing the human element; they are augmenting it by handling repetitive, high-risk, or high-volume tasks. In warehouses with high throughput, AGVs can optimize lane usage, improve safety around loading zones, and stabilize cycle times, while human operators focus on tasks that require judgment and dexterity. The integration of smart fleet management platforms, predictive maintenance, and remote diagnostics creates a feedback loop that makes every asset more reliable and more productive. When service providers combine hardware, software, and skilled human capital, they deliver an integrated solution that reduces downtime, improves accuracy, and lowers risk. This integrated approach is especially valuable in sectors where uptime equates to revenue—be it consumer electronics, automotive parts, or perishables. It is also critical to safety regimes that impose more stringent standards as operations scale. The contemporary lift truck services landscape has become a convergence zone where safety culture, environmental stewardship, and productivity ambitions intersect. A modern service model does not wait for a failure to occur; it anticipates wear patterns, manages battery fleets, and coordinates service windows to minimize impact on the workday. This approach not only preserves asset value but also protects workers, whose safety is the most tangible return on investment in a facility’s operational strategy. The shift toward proactive, data-driven service is also a response to the volatility of supply chains. When demand swings or disruptions occur, the ability to reconfigure fleets quickly and with reliable guidance becomes a competitive advantage. In this arena, training remains foundational. Operators must be proficient in new technologies and powertrains, while maintenance technicians must interpret sensor data and respond with precise, timely interventions. The emphasis on training is echoed across industry discussions and is further reinforced by public narratives on the importance of maintenance in preserving uptime and safety. For readers seeking practical context, consider the broader emphasis on maintenance training in related industrial equipment sectors, where dedicated programs highlight how a structured curriculum can boost uptime and reduce risk. fire-truck maintenance training importance The convergence of equipment reliability, safety, and productivity also creates a favorable climate for investment in infrastructure. The market’s growth forecast, coupled with the push for cleaner energy and automation, signals an era in which service providers must offer not only parts and repairs but a holistic, data-informed lifecycle of equipment. Customers are increasingly adopting leasing arrangements and service contracts that bundle maintenance, telematics, and training into predictable operating expenses. This shift is not a gimmick; it is a strategic response to the realities of modern logistics—where the cost of downtime and the cost of unplanned breakdowns can exceed the initial price of the equipment itself. In this sense, the value proposition of a one lift truck services partner is measured by more than response times or the speed of a repair. It is defined by the ability to predict, prevent, and perform in a way that keeps a facility aligned with its service-level commitments and customer promises. The future holds even more possibility as the industry continues to blend hardware, analytics, and human expertise. The trajectory toward electrified, automated, and smarter fleets necessitates a service model that is equally sophisticated: integrated planning, real-time condition monitoring, and flexible, scalable support that can adapt as new applications and processes emerge. When a warehouse expands its footprint or a distribution center revises its inbound-outbound logic, the lift truck services partner must be ready with the right expertise, the right equipment, and the right digital tools to guide the transition. The strategic implication for operators and executives is clear. Investment in comprehensive lift truck services is an investment in operational resilience, in compliance with evolving safety and environmental standards, and in the capacity to grow without sacrificing performance. The numbers are not abstract: GDP contribution, job creation, and a forecasted market expansion all point to a sector that matters far beyond the docks and warehouse floors. For readers who want to explore practical illustrations of how these principles play out in real-world operations, a deeper dive into maintenance training and its role in uptime can be found at fire-truck-maintenance-training-importance. This emphasis on continuous learning and preventive care is the connective tissue that unites economic significance with day-to-day performance. As the industry looks ahead, the overarching message is one of alignment: align equipment lifecycle with risk management, align technology with human skill, and align supplier capabilities with the strategic ambitions of the organizations they serve. In doing so, lift truck services do more than keep pallets moving; they reinforce an economy that relies on dependable logistics to deliver goods, sustain jobs, and enable growth across industries. For a broader macro perspective on the scale and scope of this transformation, readers may consult the Economic Impact Report 2026 from a leading industry association. This document frames the conversation about how investment in lift truck services translates into measurable economic outcomes and sets the stage for ongoing conversations about efficiency, safety, and sustainable progress across the supply chain.

Final thoughts

In summary, the lift truck services industry is integral to seamless logistics operations and plays a pivotal role in meeting the needs of long-haul truck drivers, fleet managers, and aspiring drivers alike. Understanding maintenance, training, and innovations is key to thriving in this space. As the market evolves, staying informed and proactive will ensure that you can leverage these services effectively, drive success, and enhance operational efficiency.