Pump Capacity

The capacity of fire pumps, typically ranging from 500 to 3,000 gallons per minute (GPM), is crucial in firefighting operations. Adequate pump capacity ensures sufficient water flow to suppress fires effectively, while insufficient capacity can lead to dire consequences.

Standard Fire Pump Capacities

According to the National Fire Protection Association (NFPA) 1901 standard, the minimum rated capacity for a standard fire pumper is 750 GPM at 150 psi. Modern municipal pumpers often have capacities of 1,000, 1,250, 1,500, or even 2,000 GPM. High-capacity pumpers, especially those designed for industrial or airport use, can exceed 3,000 GPM. These higher capacities are essential in areas with high fire risks requiring continuous and powerful water supplies.

Impact of Insufficient Water Supply

The importance of adequate pump capacity is underscored by incidents where water supply deficiencies have severely hampered firefighting efforts. For instance, South County Fire experienced a troubling 30% incident rate of running out of water before reaching a hydrant connection in emergencies. This deficiency illustrates the critical nature of ensuring that every fire truck is equipped with pumps that meet the demands of their operational environment. If crews are unable to secure a reliable water source quickly, the effectiveness of their response is jeopardized, amplifying risks to life and property.

In summary, fire pump capacities between 500 and 3,000 GPM are vital for effective firefighting. Adequate capacity ensures that sufficient water is available to combat fires, while insufficient capacity can lead to catastrophic outcomes, highlighting the importance of selecting the right pump capacity for operational efficiency in any firefighting scenario.

Best Practices in Pumper Fire Truck Design

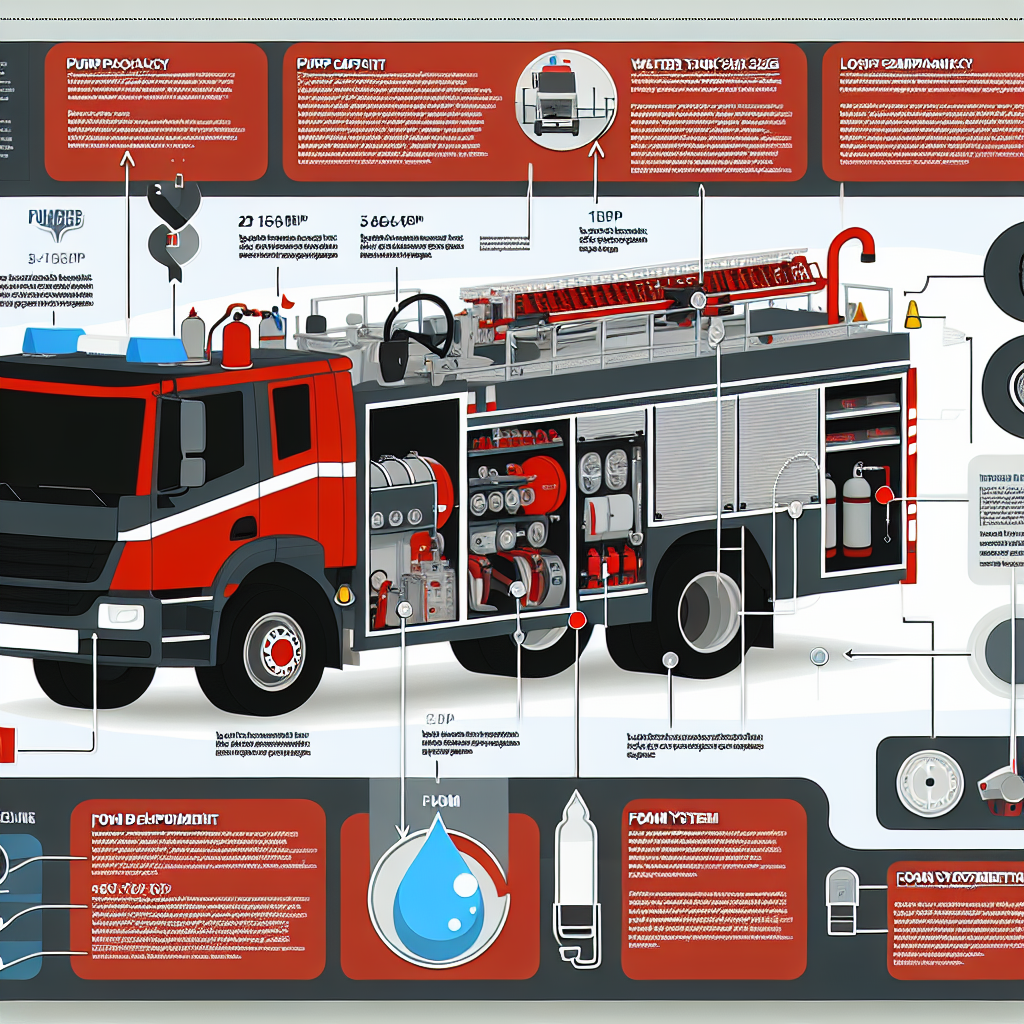

Designing an efficient pumper fire truck involves key considerations regarding water tank size, pump capacity, and foam systems, ensuring effectiveness in emergency situations. It is also essential to incorporate fire truck safety features to guarantee the safety of firefighters during operations. Below are the best practices based on industry standards:

Water Tank Size

-

Urban Areas: Typically feature water tanks ranging from 500 to 1,000 gallons. This allows for immediate water supply before connecting to external sources, which is crucial for initial attack operations.

Fire Rescue Truck -

Rural Areas: Fire trucks in these areas often carry larger tanks, sometimes up to 2,000 gallons, to accommodate longer response times without hydrant access.

Fire Rescue Truck -

Tank Materials: Modern tanks are often constructed from nonmetallic materials like plastic or fiberglass, which help prevent corrosion and reduce weight.

Fire Engineering

Pump Capacity

-

Standard Configurations: Common flow rates for fire pumps typically range from 1,500 gallons per minute (gpm). This ensures versatility for a range of firefighting needs.

Firehouse -

High Capacity Pumps: Some departments may require pumps that can deliver up to 2,250 gpm based on the risk factors of their response area.

Firehouse

Foam Systems

-

Foam Proportioning: Direct injection systems are considered best for their accuracy and efficiency in foam application.

Firehouse -

Compressed Air Foam Systems (CAFS): Effective for structure fires, requiring at least 250 gpm pump capacity alongside adequate air compressor size.

Firefighter Nation

Examples of Effective Designs

-

Oshkosh Striker 1500: Features a 1,500-gallon water tank, 210-gallon foam tank, and a pump delivering up to 750 gpm, ideal for rapid response.

Wikipedia -

Rosenbauer Panther 8×8: Equipped with a massive 14,500-liter water tank and advanced foam systems, tailored for high-demand firefighting.

Wikipedia -

CET Firepump Brush Truck 6: Built for wildland firefighting with a 300-gallon water tank and integrated foam cell, balancing agility with effectiveness.

Fire Pump

By aligning design features with operational requirements, including fire truck safety features, fire departments can ensure their pumper trucks are well-equipped for varied firefighting scenarios.

2. Pump Capacity

The pump capacity, usually ranging from 500 to 3,000 gallons per minute (GPM), greatly affects how efficiently firefighters respond to incidents. Fire departments need to evaluate the risks in their working environments and select pumps that can meet these demands.

If the pump capacity is inadequate, it can delay firefighting efforts and put lives and property at greater risk. Choosing the right pump ensures a strong and steady water flow, helping firefighters to effectively tackle fires.

Comparative Overview of Pumper Truck Models

Here’s a comparison table showcasing different pumper truck models based on pump capacity, water tank size, and foam system capabilities from Pierce Manufacturing and Oshkosh Corporation:

| Model Name | Manufacturer | Pump Capacity | Water Tank Size | Foam System |

|---|---|---|---|---|

| Sheboygan Fire Department Pumper | Pierce Manufacturing | 1,500 GPM | 750 gallons | Husky™ 3 |

| Dallas Fire-Rescue Pumper | Pierce Manufacturing | 1,500 GPM | 500 gallons | Husky™ 3 |

| Rochester Fire Department Pumper | Pierce Manufacturing | 1,500 GPM | 600 gallons | Husky™ 12 |

| Lakeland Fire Department Pumper | Pierce Manufacturing | 1,250 GPM | 1,000 gallons | Husky™ 3 |

| Fort Wayne Fire Department Pumper | Pierce Manufacturing | 1,500 GPM | 750 gallons | Husky™ 3 |

| Wisconsin Rapids Fire Department Pumper | Pierce Manufacturing | 1,500 GPM | 750 gallons | Husky™ 12 |

| Oshkosh P-19R ARFF Vehicle | Oshkosh Corporation | 750 GPM | 1,000 gallons | 130-gallon foam |

| Striker 1500 | Oshkosh Corporation | 1,500 GPM | 1,500 gallons | 210-gallon foam |

| Striker 3000 | Oshkosh Corporation | 3,000 GPM | 3,000 gallons | 420-gallon foam |

| Striker 4500 | Oshkosh Corporation | 4,500 GPM | 4,500 gallons | 630-gallon foam |

This table summarizes key specifications and features of different fire pumper models, illustrating the variety available to fire departments based on their operational needs.

Pumper Fire Truck Performance Statistics

Key Metrics

-

Average Pump Capacity:

Standard pumpers are typically equipped with pumps rated from 1,000 to 2,000 GPM, adhering to the NFPA minimum standard of 750 GPM. High-capacity units can exceed 3,000 GPM for specialized applications. (source) - Standard Water Tank Sizes:

-

Foam System Functionalities:

Foam tanks range from 20 to 500 gallons based on the unit’s design. Some modern pumpers, such as the Darley Tactical Pumper, can deliver 900 to 1,200 gallons of usable fire suppression agent when equipped with CAFS. (source)

Design Impact

The design of pumper fire trucks plays a critical role in shaping both response times and the overall safety of firefighters. Features such as hosebed height and ladder accessibility are paramount in ensuring that firefighters can operate efficiently and effectively during emergencies.

Hosebed Height

The height of the hosebed is essential for rapid hose deployment. Pumper trucks designed with lower hosebed heights enable firefighters to access hoses easily, reducing the time spent retrieving and deploying them. This feature is particularly crucial in high-pressure situations, where every second counts. Lower hosebeds also help to minimize physical strain on firefighters, decreasing the risk of injury during urgent operations. In contrast, trucks with higher hosebeds may slow down response times and hinder efficiency.

Ladder Accessibility

Ladder accessibility is another vital design element. Fire trucks equipped with easily deployable ladders allow firefighters to quickly reach elevated areas, whether for rescue operations or to combat roof fires. Features such as automatic ladder systems or strategically placed ladder storage can enhance safety while enabling a swift response. A well-designed pumper with accessible ladders ensures that firefighters can provide assistance promptly, further protecting lives and property during emergencies.

Overall, thoughtful design in pumper truck engineering can greatly enhance response effectiveness and safeguard the firefighters dedicated to serving their communities.

Tank Size Statistics

Standard water tank sizes on fire trucks are fundamental to their firefighting effectiveness. Urban fire trucks generally feature water tanks that hold between 500 and 1,000 gallons. This sizing takes advantage of the proximity to hydrants, enabling rapid refills and facilitating lighter, more maneuverable apparatus suitable for congested environments. Conversely, rural fire trucks are outfitted with larger tanks, typically ranging from 1,500 to 3,000 gallons. This is essential in areas lacking hydrants, ensuring that firefighters have adequate water supply for initial response before additional resources can reach the scene.

The correlation between tank size and operational efficiency is crucial. For example, a fire truck with a 500-gallon tank using a standard hose line that dispenses approximately 150 gallons per minute (GPM) would deplete its water supply in a matter of minutes. This highlights the importance of ensuring access to a continuous water source during extended firefighting operations. Notably, most modern fire engines boast pump capacities between 1,000 and 2,000 GPM, which supports effective water delivery regardless of tank capacity.

Standard Tank Sizes for Urban and Rural Fire Trucks:

- Urban Fire Trucks: Typically equipped with water tanks ranging from 500 to 1,000 gallons. Urban areas have extensive hydrant networks, allowing these trucks to rely more on external water sources.

- Rural Fire Trucks: Often feature larger tanks, holding between 1,500 to 3,000 gallons, to compensate for limited hydrant availability. Some rural departments utilize pumper-tankers with capacities up to 3,000 gallons.

Impact on Firefighting Operations:

- Urban Settings: Smaller tanks enhance maneuverability, reduce vehicle weight, and facilitate quicker response times.

- Rural Settings: Larger tanks are essential for sustaining operations until additional water sources are established, but can also affect stability and efficiency.

These examples illustrate the diversity in fire truck designs, each tailored to specific operational requirements and environments.

For instance, the Pierce Enforcer Pumper has approximately 500 gallons, while the Scania 6×4 Rural Tanker holds around 2,400 gallons. Modern models, like the Rosenbauer Panther ARFF, can feature capacities ranging from 2,900 to 4,000 gallons.

These tank sizes are specifically designed to suit the varied demands of different firefighting scenarios, reinforcing the importance of efficient water tank design to overall fire suppression effectiveness.

Conclusion

In conclusion, the design considerations for pumper fire trucks are not merely technical specifications; they are a commitment to enhancing the efficacy of emergency response and the safety of firefighters. As highlighted throughout this article, critical aspects such as pump capacity, water tank size, and the placement of hoses play pivotal roles in tailoring fire apparatus to meet the unique operational needs of different fire departments. The significance of thoughtful design cannot be overstated, as it directly impacts the effectiveness of firefighting efforts. As one industry expert aptly notes, “Developing the right apparatus starts with asking the right questions.” This principle reminds us that understanding specific requirements and challenges faced by first responders is essential in creating pumper fire trucks that genuinely serve their purpose. By emphasizing customization and operational needs, fire departments can ensure their apparatus provides the utmost support during emergencies, ultimately safeguarding lives and property in the communities they are sworn to protect.

Conclusion

In conclusion, the design considerations for pumper fire trucks are not merely technical specifications; they are a commitment to enhancing the efficacy of emergency response and the safety of firefighters. As highlighted throughout this article, critical aspects such as pump capacity, water tank size, and the placement of hoses play pivotal roles in tailoring fire apparatus to meet the unique operational needs of different fire departments. The significance of thoughtful design cannot be overstated, as it directly impacts the effectiveness of firefighting efforts. As one industry expert aptly notes, “Developing the right apparatus starts with asking the right questions.” This principle reminds us that understanding specific requirements and challenges faced by first responders is essential in creating pumper fire trucks that genuinely serve their purpose. By emphasizing customization and operational needs, fire departments can ensure their apparatus provides the utmost support during emergencies, ultimately safeguarding lives and property in the communities they are sworn to protect. Moreover, embracing advanced fire truck technology will further empower fire services to ensure readiness and response capabilities are consistently optimized, allowing for effective firefighting in the face of increasingly complex challenges.

Call to Action

As you consider the design and selection of a pumper fire truck, remember the essential features discussed in this post that could influence operational success: pump capacity, water tank size, foam systems, and accessibility. These considerations are not just technical specifications; they can significantly enhance the effectiveness and safety of your firefighting operations. Engage with your team, evaluate these elements critically, and choose a pumper design that serves your community’s unique needs. Make informed decisions today to equip your first responders with the best possible tools to combat fires and protect lives.

Call to Action

As you consider the design and selection of a pumper fire truck, remember the essential features discussed in this post that could influence operational success: pump capacity, water tank size, foam systems, and accessibility. These considerations are not just technical specifications; they can significantly enhance the effectiveness and safety of your firefighting operations. Engage with your team, evaluate these elements critically, and choose a pumper design that serves your community’s unique needs.

“Although tankers account for only 3% of the total fire apparatus in the U.S., they contribute to over 20% of firefighter fatalities related to responses.”

Make informed decisions today to equip your first responders with the best possible tools to combat fires and protect lives.