Pumper fire trucks play a crucial role in the firefighting and emergency response ecosystem, acting as the first line of defense during emergencies. As one of the most frequently deployed pieces of equipment in a fire department’s fleet, the design of these trucks directly impacts operational effectiveness and firefighter safety. Fire departments across the globe face unique challenges that require pumper trucks to be custom-tailored to meet specific local needs, ranging from varied terrain to the types of hazards encountered in their jurisdiction. Features such as pump capacity, tank size, and hose bed organization are vital components that influence a truck’s performance.

“Thoughtful pumper design maximizes operational efficiency and firefighter safety.”

The thoughtful design and adaptability of pumper trucks ensure that firefighting professionals have the tools they need to respond quickly and effectively to any emergency situation, highlighting the significance of strategic customization in enhancing operational readiness and supporting the safety of both responders and the communities they serve.

Pump Capacity in Pumper Fire Trucks

Pump capacity is a critical component in the design of pumper fire trucks, as it determines how much water can be delivered in emergency situations. Fire truck pump capacities typically range from 500 to 3,000 gallons per minute (GPM), and understanding these ratings is vital for fire departments when selecting apparatus that meets their operational needs.

Key Points on Pump Capacity:

- 500 to 750 GPM:

- Commonly found in smaller or wildland fire engines.

- Suited for initial attack operations or areas with limited water supply infrastructure.

- Provides ample flow for small fires and can support one or two hose lines.

- 1,000 to 1,500 GPM:

- The standard range for municipal pumper trucks.

- Ideal for residential and commercial structural fires where multiple attack lines may be required.

- Can supply one tower ladder or up to three deluge sets when sufficient water source is available.

- 2,000 to 3,000+ GPM:

- Found in industrial or high-capacity fire trucks.

- Designed for large-scale operations such as those required for high-rise buildings or areas without immediate water sources.

- Enhances firefighting capabilities during significant emergencies that demand a high volume of water.

Importance of Pump Capacity:

- The volume of water a pump can deliver directly impacts the ability to suppress and extinguish fires efficiently.

- Adequate flow rates are essential; for instance, relying on a pump that cannot meet the water demand will hinder firefighting effectiveness.

- The operational setup, including the connection to the water supply and the type of pump, plays a significant role in achieving the desired performance during emergencies.

Factors Affecting Pump Performance:

- Water Source Availability:

A pump’s effectiveness can be limited by the available water supply. If a truck has a rated capacity of 1,000 GPM but is connected to a hydrant only yielding 600 GPM, its full potential cannot be realized.

- Pump Type:

Two-stage pumps are beneficial because they allow operators to switch between high-pressure and high-volume modes, amplifying performance across different firefighting scenarios.

- Maintenance and Reliability:

Regular inspections and maintenance of pumps are necessary to ensure they operate at peak efficiency. Neglecting pump upkeep can lead to failures during emergencies, which could adversely affect firefighting operations.

In summary, understanding the pump capacity and ensuring it’s appropriately matched with the anticipated operational demands is vital for fire departments when designing and purchasing pumper trucks. This alignment not only enhances operational effectiveness but also ensures the safety and efficiency of fire response teams in the field.

Key Points on Pump Capacity:

- 500 to 750 GPM:

- Commonly found in smaller or wildland fire engines.

- Suited for initial attack operations or areas with limited water supply infrastructure.

- Provides ample flow for small fires and can support one or two hose lines.

- 1,000 to 1,500 GPM:

- The standard range for municipal pumper trucks.

- Ideal for residential and commercial structural fires where multiple attack lines may be required.

- Can supply one tower ladder or up to three deluge sets when sufficient water source is available.

- 2,000 to 3,000+ GPM:

- Found in industrial or high-capacity fire trucks.

- Designed for large-scale operations such as those required for high-rise buildings or areas without immediate water sources.

- Enhances firefighting capabilities during significant emergencies that demand a high volume of water.

- The volume of water a pump can deliver directly impacts the ability to suppress and extinguish fires efficiently.

- Adequate flow rates are essential; for example, relying on a pump that cannot meet the water demand will hinder firefighting effectiveness.

- The operational setup, including the connection to the water supply and the type of pump, plays a significant role in achieving the desired performance during emergencies.

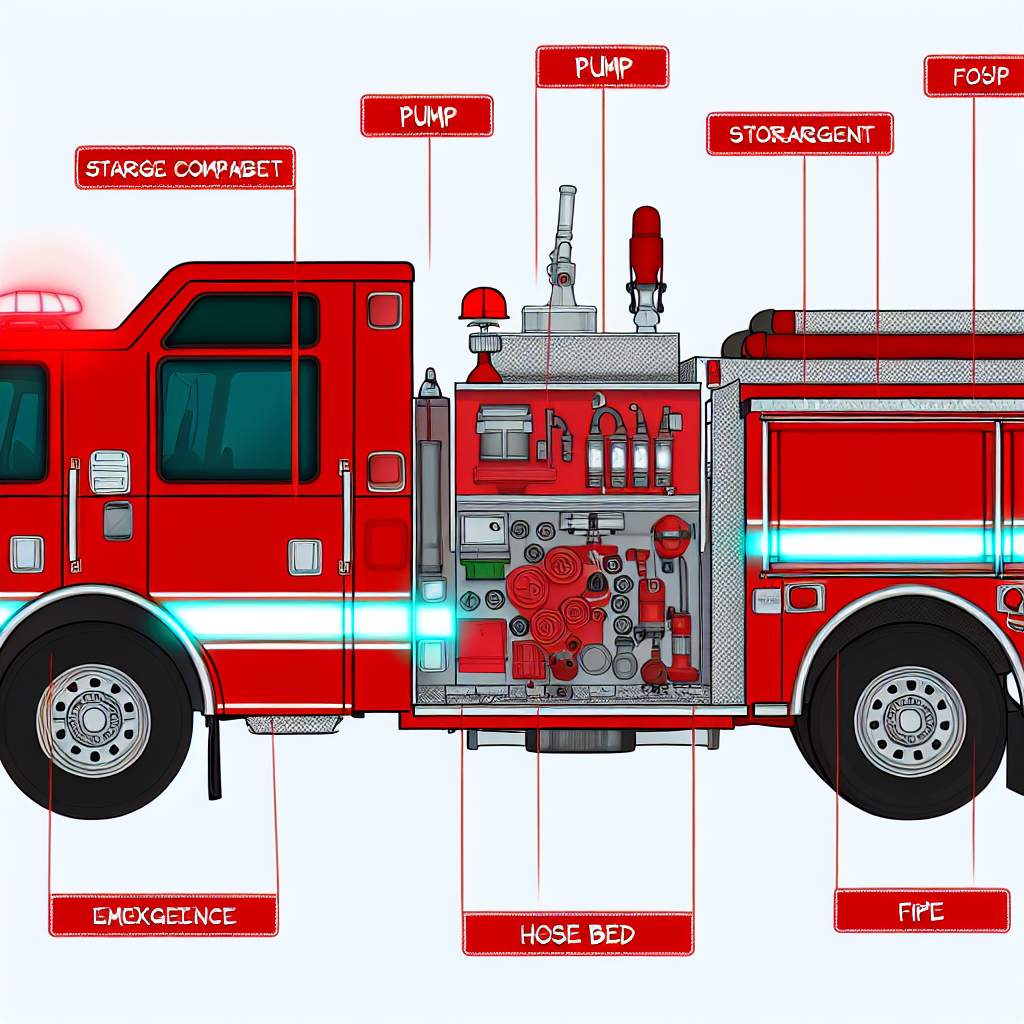

An illustration of a pumper fire truck showing key features such as pump, storage compartments, and hose bed.

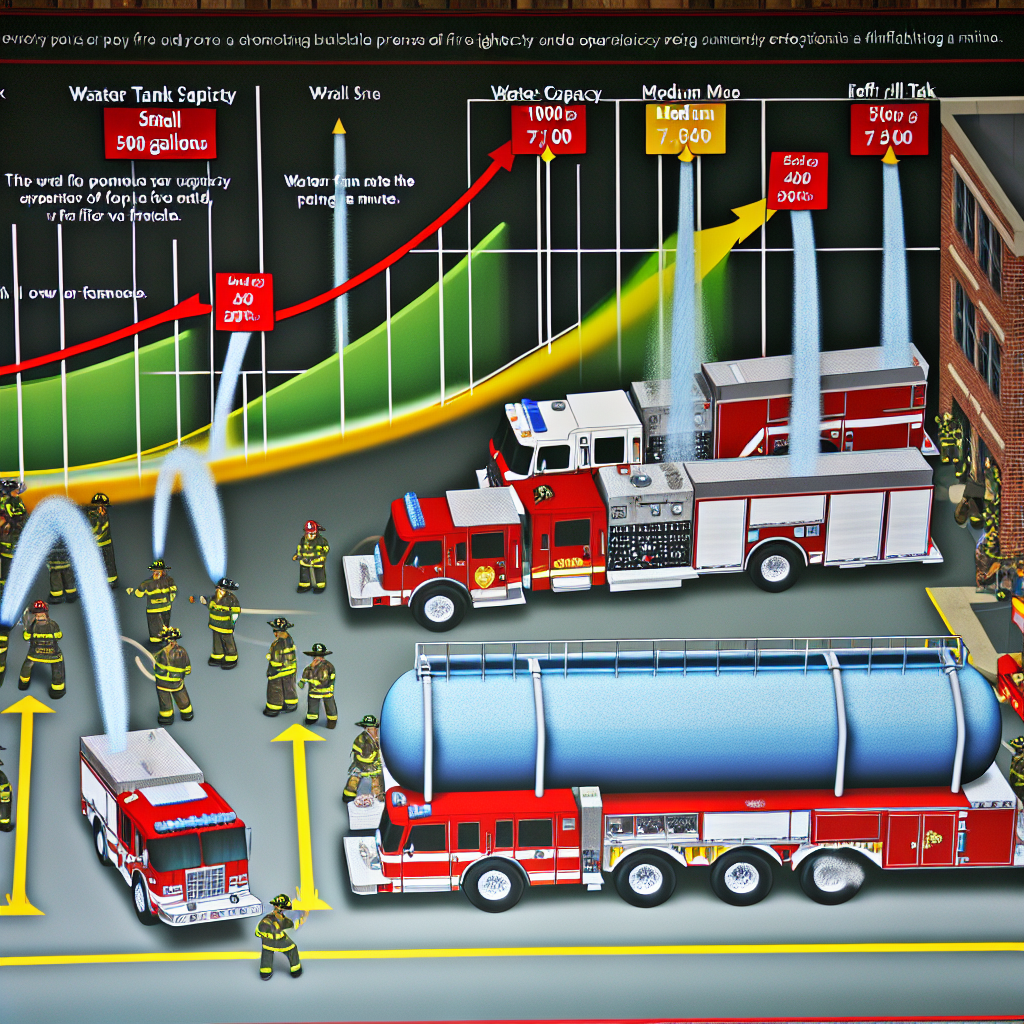

Standard Tank Size of 750 Gallons

When it comes to pumper fire trucks, the tank size plays a vital role in determining operational efficiency during emergency response. The standard tank size for most pumper trucks is 750 gallons, a capacity that strikes a balance between weight, maneuverability, and firefighting effectiveness. Having a sufficient water supply on board allows firefighting teams to respond promptly to incidents without the immediate need for external water sources.

One significant finding from South County Fire emphasizes the critical nature of tank capacity: they reported that existing apparatus ran out of water during nearly 30% of incidents before a hydrant connection could be established. This statistic illustrates how a lack of adequate water supply can severely hinder firefighting efforts at a crucial moment. In many emergencies, every second counts; thus, ensuring that fire trucks possess adequate tank capacity is imperative.

The 750-gallon tank size enables firefighters to engage effectively with various incidents, from small residential fires to larger structures, by providing sufficient water for initial suppression efforts. Moreover, it allows crews to establish a command and control structure on the scene, cooling hotspots, making rescues, and securing an environment for additional responding units.

In addition, having this capacity supports multi-hose operations, particularly in residential areas where layout and water access can be limited. When initial fire attack lines are deployed, this onboard water allows firefighters to maintain a steady flow until a hydrant connection can be made.

Ultimately, the 750-gallon standard tank size is a fundamental aspect of pumper fire truck design that significantly enhances firefighting efficiency. By ensuring that apparatus is equipped to provide an adequate initial water supply, fire departments can improve their operational readiness and effectiveness in combating fires.

| Model | Tank Size (gallons) | Pump Capacity (GPM) | Hose Bed Height (inches) |

|---|---|---|---|

| Pierce Enforcer | 750 | 1,500 | 36 |

| Oshkosh Striker | 1,000 | 2,000 | 30 |

| E-One Cyclone | 500 | 1,000 | 32 |

This table compares essential features of various pumper fire truck models, highlighting their tank sizes, pump capacities, and hose bed heights, which are critical for effective firefighting operations.

Importance of Effective Storage Organization in Pumper Trucks

Effective storage organization in pumper trucks serves as the backbone of operational efficiency. Each piece of equipment, from hoses to axes, needs to be strategically placed so that it can be quickly and easily accessed during emergencies. When seconds count, the ability of firefighters to retrieve necessary tools without fumbling or wasting time is paramount.

Consider a real-world scenario: during a large structure fire, a fire crew receives a call while they are already engaged in another incident. When they arrive, the pressure is on, and the chaos of emergency response can lead even the most seasoned professionals to become disoriented if their equipment is not organized. In such high-stress situations, a well-organized truck ensures that firefighters can find what they need quickly, ensuring a more swift and effective response.

The importance of thoughtful storage organization is further highlighted by examples from fire departments that have faced challenges due to inadequate organization. A fire department in California shared how transitioning to a more organized storage system significantly reduced their equipment retrieval time by almost 30%, thereby improving their operational response during incidents. This change not only enhanced their efficiency but also boosted the confidence of the firefighters, knowing that they could access what they needed in a timely manner.

Moreover, the organization of equipment inside pumper trucks can lead to increased safety. When tools are neatly stored in designated compartments, the risk of accidents during high-pressure situations is minimized. For instance, if fire axes and saws are properly secured in designated storage spaces, firefighters can access them without worry of them falling or causing injury when the truck is in motion.

In essence, effective storage organization not only enhances operational efficiency but also contributes to the overall safety of fire crews. Fire departments must consider how their pumper trucks are laid out, investing in customizable storage solutions that allow for flexible configurations tailored to their unique needs. By prioritizing organization, fire departments can elevate their readiness and response capabilities, ensuring they are always prepared to protect lives and property.

User Adoption Statistics for Pumper Fire Truck Features

In recent years, fire departments have increasingly adopted advanced features in pumper fire trucks to enhance operational efficiency and serviceability. Here are some key statistics:

- Integration of Advanced Technologies: Approximately 55% of new fire trucks now incorporate enhanced aerial platforms and ladder systems which facilitate operations in high-rise settings. Furthermore, around 35% of these trucks are equipped with smart navigation and telematics systems, enabling improved real-time decision-making and operational oversight. This modernization allows departments to respond more effectively to emergencies, particularly in complex urban environments (Global Growth Insights).

- Emphasis on Multifunctionality: About 38% of fire departments are prioritizing multifunctional trucks that serve various roles, including firefighting, rescue, and medical response. This integrated approach allows for optimized resource utilization during emergencies, as a single apparatus can handle different types of incidents without the need for multiple trucks (Global Growth Insights).

- Sustainability Initiatives: Over 22% of newly designed fire trucks feature hybrid or fully electric propulsion systems. For instance, Mesa, Arizona has introduced the state’s first electric fire truck, capable of operating four hose lines at 750 gallons per minute for up to four hours on a single charge. This shift towards greener technologies not only aligns with sustainability goals but also reduces ongoing operational costs related to fuel consumption (Axios).

- Focus on Serviceability and Design Efficiency: Manufacturers are responding to the need for greater serviceability by redesigning pumper trucks for improved access to maintenance components. The Pierce Ultimate Configuration (PUC), for instance, eliminates traditional pump houses by relocating pumps under the cab. This innovation increases compartment space and shortens the wheelbase, which significantly simplifies maintenance and enhances response capabilities (Pierce Manufacturing).

These user adoption trends illustrate a concerted effort by fire departments to not only embrace innovative designs but also ensure that their operational capabilities and serviceability match the demands of modern firefighting and emergency response environments.

Conclusion

The design of pumper fire trucks is essential for enhancing operational efficiency and ensuring firefighter safety. Here are the key takeaways:

- Pump Capacity is Vital: With capacities ranging from 500 to 3,000 gallons per minute, adequate pump capacity ensures rapid fire suppression and helps prevent fires from escalating.

- Standard Tank Size Enhances Readiness: The widely adopted 750-gallon tank size allows fire departments to have sufficient water on hand for immediate engagement without reliance on external sources, especially critical during the initial response phase.

- Effective Storage Organization: Purposeful organization of equipment within the truck is crucial for quick access during emergencies. This reduces retrieval times and boosts overall safety for firefighters operating under pressure.

- Emphasis on Advanced Technologies: As fire departments continue to integrate advanced features and technologies, such as smart navigation and multifunctional designs, they enhance both operational capabilities and response efficiency.

Fire departments must prioritize thoughtful customization in pumper truck design to maximize readiness and enhance safety. By focusing on these aspects, they can effectively protect lives and property while meeting the unique demands of their operational environments.

“Developing the right apparatus starts with asking the right questions.”

This quote from James Curtis underscores the importance of inquiry in the design process of pumper fire trucks. Asking the right questions enables designers and fire departments to identify their specific operational needs, ensuring that the final product is tailored effectively to the unique challenges they face.

An illustration showing various tank sizes and their performance in a pumper fire truck, emphasizing tank capacity, water flow rates, and operational efficiency during firefighting scenarios.

Pumper fire trucks play a crucial role in the firefighting and emergency response ecosystem, acting as the first line of defense during emergencies. As one of the most frequently deployed pieces of equipment in a fire department’s fleet, the design of these trucks directly impacts the operational effectiveness, firefighter safety, and the overall effectiveness of emergency response equipment. Fire departments across the globe face unique challenges that require pumper trucks to be custom-tailored to meet specific local needs, ranging from varied terrain to the types of hazards encountered in their jurisdiction. Features such as pump capacity, tank size, and hose bed organization are vital components that influence a truck’s performance.

“Thoughtful pumper design maximizes operational efficiency and firefighter safety.”

The thoughtful design and adaptability of pumper trucks ensure that firefighting professionals have the tools they need to respond quickly and effectively to any emergency situation, highlighting the significance of strategic customization in enhancing operational readiness and supporting the safety of both responders and the communities they serve. By integrating advanced fire truck technology, departments can further enhance their operational efficiency.

Pump Capacity in Pumper Fire Trucks

Pump capacity is a critical component in the design of pumper fire trucks, as it determines how much water can be delivered in emergency situations. Fire truck pump capacities typically range from 500 to 3,000 gallons per minute (GPM), and understanding these ratings is vital for fire departments when selecting apparatus that meets their operational needs.

Key Points on Pump Capacity:

-

500 to 750 GPM:

- Commonly found in smaller or wildland fire engines.

- Suited for initial attack operations or areas with limited water supply infrastructure.

- Provides ample flow for small fires and can support one or two hose lines.

-

1,000 to 1,500 GPM:

- The standard range for municipal pumper trucks.

- Ideal for residential and commercial structural fires where multiple attack lines may be required.

- Can supply one tower ladder or up to three deluge sets when sufficient water sources are available.

-

2,000 to 3,000+ GPM:

- Found in industrial or high-capacity fire trucks.

- Designed for large-scale operations such as those required for high-rise buildings or areas without immediate water sources.

- Enhances firefighting capabilities during significant emergencies that demand a high volume of water.

Importance of Pump Capacity:

- The volume of water a pump can deliver directly impacts the ability to suppress and extinguish fires efficiently.

- Adequate flow rates are essential; for instance, relying on a pump that cannot meet the water demand will hinder firefighting effectiveness.

- The operational setup, including the connection to the water supply and type of pump, plays a significant role in achieving the desired performance during emergencies.

Factors Affecting Pump Performance:

-

Water Source Availability:

A pump’s effectiveness can be limited by the available water supply. If a truck has a rated capacity of 1,000 GPM but is connected to a hydrant only yielding 600 GPM, its full potential cannot be realized.

-

Pump Type:

Two-stage pumps are beneficial because they allow operators to switch between high-pressure and high-volume modes, amplifying performance across different firefighting scenarios.

-

Maintenance and Reliability:

Regular inspections and maintenance of pumps are necessary to ensure they operate at peak efficiency. Neglecting pump upkeep can lead to failures during emergencies, which could adversely affect firefighting operations.

In summary, understanding the pump capacity and ensuring it’s appropriately matched with anticipated operational demands is vital for fire departments when designing and purchasing pumper trucks. This alignment not only enhances operational effectiveness but also ensures the safety and efficiency of fire response teams in the field.

Standard Tank Size of 750 Gallons

When it comes to pumper fire trucks, the tank size plays a vital role in determining operational efficiency during emergency response. The standard tank size for most pumper trucks is 750 gallons, a capacity that strikes a balance between weight, maneuverability, and firefighting effectiveness. Having a sufficient water supply on board allows firefighting teams to respond promptly to incidents without the immediate need for external water sources.

One significant finding from South County Fire emphasizes the critical nature of tank capacity: they reported that existing apparatus ran out of water during nearly 30% of incidents before a hydrant connection could be established. This statistic illustrates how a lack of adequate water supply can severely hinder firefighting efforts at a crucial moment. In many emergencies, every second counts; thus, ensuring that fire trucks possess adequate tank capacity is imperative.

The 750-gallon tank size enables firefighters to engage effectively with various incidents, from small residential fires to larger structures, by providing sufficient water for initial suppression efforts. Moreover, it allows crews to establish a command and control structure on the scene, cooling hotspots, making rescues, and securing an environment for additional responding units.

Ultimately, the 750-gallon standard tank size is a fundamental aspect of pumper fire truck design that significantly enhances firefighting efficiency. By ensuring that apparatus is equipped to provide an adequate initial water supply, fire departments can improve their operational readiness and effectiveness in combating fires.

Importance of Effective Storage Organization in Pumper Trucks

Effective storage organization in pumper trucks serves as the backbone of operational efficiency, especially in emergency response situations. Each piece of equipment, from hoses to axes, needs to be strategically placed so that it can be quickly and easily accessed during emergencies. When seconds count, the ability of firefighters to retrieve necessary tools without fumbling or wasting time is paramount.

Moreover, the organization of equipment inside pumper trucks can lead to increased safety. When tools are neatly stored in designated compartments, the risk of accidents during high-pressure situations is minimized. For instance, if fire axes and saws are properly secured in designated storage spaces, firefighters can access them without worry of them falling or causing injury when the truck is in motion.

In essence, effective storage organization not only enhances operational efficiency but also contributes to the overall safety of fire crews. Fire departments must consider how their pumper trucks are laid out, investing in customizable storage solutions that allow for flexible configurations tailored to their unique needs. By prioritizing organization, fire departments can elevate their readiness and response capabilities, ensuring they are always prepared to protect lives and property.

Ultimately, the integration of fire truck technology into pumper truck design signifies an important advancement in the firefighting field, enhancing firefighter safety and operational efficiency. As fire departments continue to embrace these innovations, they can provide superior emergency response equipment that effectively meets the demands of modern firefighting and emergency response operations.