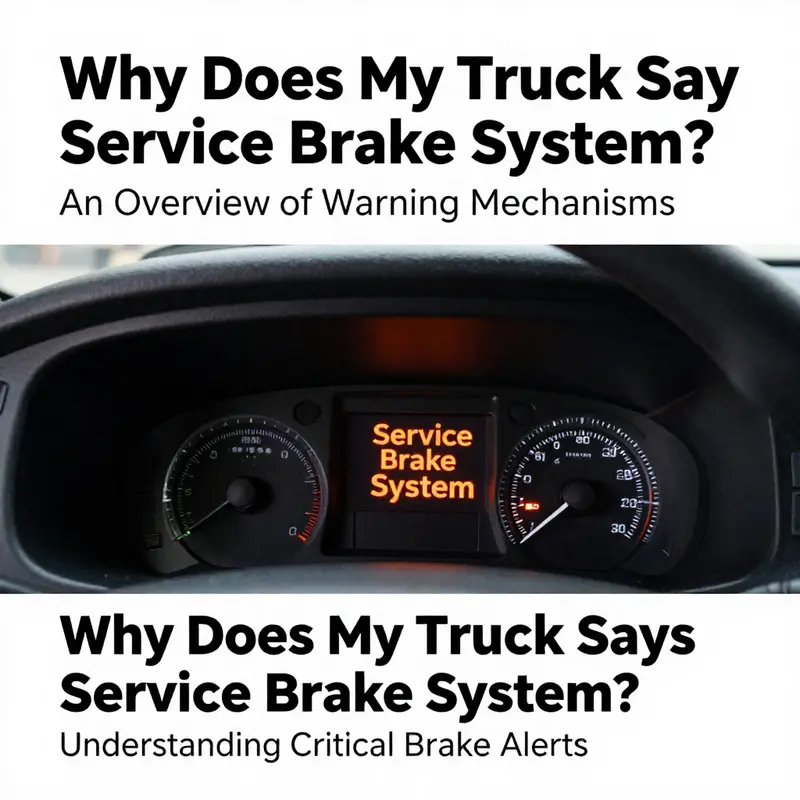

When your truck displays the warning “Service Brake System,” it’s more than a mere alert; it’s a crucial signal for your safety. Addressing braking system issues is of utmost importance, especially for long-haul truck drivers and fleet managers. This article aims to provide a thorough understanding of why these warnings occur, the common causes behind them, and immediate actions you should take to ensure not just compliance, but the safety of you and others on the road. In the following chapters, we’ll explore an overview of warning mechanisms, diagnose common brake issues, and discuss proactive measures to maintain the integrity of your vehicle’s braking system.

null

null

Decoding the Service Brake System Warning: Reading the Light, Understanding Causes, and Safely Returning to the Road

When the dash light blinks or a stark message appears—Service Brake System, Check Brake System, or something similar—the immediate impulse should be caution, not curiosity. The braking system is the one safety feature you cannot improvise via experience alone. It is a complex, interlocked network that converts pedal pressure into hydraulic force, coordinates with sensors and modules, and, in many modern trucks, governs how and when the ABS engages to prevent lockup. A warning like this is not a nuisance; it is a signal that something in that system is not performing as it should. The moment you see it, you are facing a potential reduction in stopping power, a change in pedal feel, or even a complete failure of one or more braking functions. The stakes are high enough that the prudent driver prioritizes safety and professional diagnosis over continued highway miles. The path from warning to repair is rarely, if ever, a simple one, but it is a path you can navigate with a calm plan, attention to detail, and a clear sense of what could be happening beneath the hood, in the lines, or inside the digital brain of the vehicle.

The warning light is designed to be broad in its implication. It does not always point to a single failed component; rather, it can illuminate due to a handful of issues that, individually, might not completely disable braking but together compromise performance enough to warrant concern. The most frequent culprits fall into a few broad categories: hydraulic system integrity, physical wear, electronic sensing, and electrical or software-related faults. Understanding these categories helps you reason through what you can check safely, what you should avoid attempting on your own, and when it’s time to call a professional. In practice, the driver’s job is to preserve control, keep the vehicle in a safe lane position, and arrange for a professional diagnostic that reads the vehicle’s fault codes with a proper scanner and the appropriate service procedures.

One of the most common and readily verifiable causes is the brake fluid system. The hydraulic nature of most modern braking means that if the fluid level is too low, or the fluid is contaminated, or air has entered the lines, the system cannot transmit the force you apply at the pedal with the same reliability. Low brake fluid is often the simplest explanation, and yet it can be the sign of a bigger problem such as a leak or worn components. When pads wear down, the caliper and fluid movement can be affected in subtle ways. Worn pads may trigger an alert, particularly in vehicles equipped with pad wear sensors. A squealing or grinding noise when applying the brakes is another clue that the pads need attention, and the warning light may reflect a change in braking performance rather than a mechanical failure alone. The fluids themselves carry warning signs; a dark or contaminated brake fluid can indicate moisture ingress or material breakdown within the hydraulic system. If you park the truck and notice a puddle of fluid beneath the wheels, or near the lines and calipers, that is a clear, serious indicator of a leak and a reason to avoid driving the vehicle.

Beyond fluid concerns, the state of the brake rotors and pads themselves can trigger the warning through the ABS or the pressure sensors that monitor rotor velocity and pad engagement. Warped or uneven rotors are among the most common mechanical culprits, especially in trucks that endure heavy loads, frequent mountain descents, or repeated hard braking. When rotors warp, heat distortion creates local thickness variations. The result can be a pedal that feels pulsatile or a steering wheel that shivers as you brake. The ASB system, tuned to detect irregular rotations, can set off the warning when it senses inconsistent rotor behavior even if the rotor looks visually intact. You might not see obvious grooves or scoring, but the rotor surface can be uneven enough to upset the sensor readings during deceleration. This is one reason why a rotor that appears sound can still be the root cause of a service brake warning.

The brake fluid network is also a frequent source of trouble in its own right. Air in the lines can make the brake pedal feel spongy, increasing stopping distance, and can feed into an ABS fault code. Contaminants—from water, rust inhibitors, or other impurities—can degrade the fluid’s ability to transmit hydraulic force consistently. If you suspect air in the lines, a professional will usually bleed the brakes to purge air and restore pressure continuity. Contamination is less forgiving; it can alter the boiling point of the fluid and accelerate corrosion within the master cylinder, calipers, and wheel cylinders. These are not issues you should try to address by topping up fluid alone. While adding the correct type of brake fluid may seem like a straightforward fix, it is indeed a diagnostic step that must be paired with verification of fluid level, condition, and system integrity.

Electrical and electronic elements contribute a large portion of modern brake-system complexity. Short circuits in the vehicle’s computer or wiring harness can trigger false positives, while actual failures in sensors—whether they monitor pad wear, rotor speed, wheel speed, or hydraulic pressure—can illuminate the warning light even when braking feels mostly normal. ABS issues, in particular, can cause a light to come on because the system detects abnormal rotor speed or a fault in the control module. In some cases, a fault in the brake light switch can also trigger the warning by signaling to the computer that something is off within the braking circuit. For the driver, this means that a bright indicator on the dash could reflect a sensor glitch, but it could equally reflect a genuine problem in one of the control circuits. The margin between “false alarm” and “real danger” can be narrow, so treating the warning as a serious maintenance alert is the safest approach.

The pads themselves are not immune to triggering the warning either. When pads wear to a critical thickness, the sensors designed to detect wear can send a signal to the truck’s computer. In many vehicles, a pad-thickness alert is part of the integrated safety system to prevent the driver from running the vehicle with insufficient braking material. Depending on driving conditions and vehicle design, you might also notice a high-pitched squeal as a marginally worn pad triggers its sensor. Even if the visual inspection of the pads seems inconclusive, the warning light is a call to action rather than a verdict on pad condition. A professional inspection will verify pad wear, calliper operation, and rotor condition, along with a check of brake fluid levels and the ABS network.

In short, the Service Brake System warning is a multi-axial alert. It is designed to prevent dangerous driving conditions by prompting a diagnostic. It is not a cue to push through a stubborn issue or to hope for a temporary fix. The prudent response is to reduce speed, avoid aggressive stops, and schedule a diagnostic with a qualified technician who can interpret the vehicle’s fault codes in the context of the truck’s operating history and the specifics of the current drive conditions. The diagnostic process typically begins with a scan of the fault codes stored in the engine and brake-control modules. The codes reveal the likely faulting subsystem and can guide the technician to check for fluid issues, sensor faults, rotor conditions, and any evidence of leaks or electrical faults. Without this digital map, you are guessing at what is a highly integrated mechanical-electrical system with multiple fail-safes and cross-checks.

From a practical standpoint, there are immediate steps that any driver can take to manage risk after the warning appears, even before a professional inspection. First, avoid aggressive driving. Do not accelerate hard, brake hard, or engage in rapid maneuvers. Second, check the brake fluid level with the hood raised and the engine off, and confirm that you are using the correct type of brake fluid for your system. If the level is below the minimum mark, a top-up may temporarily improve hydraulic pressure, but it is not a substitute for diagnosing the cause of loss. Look for signs of leaks around the master cylinder, along the lines, at the calipers, and beneath the vehicle. A pool or wet patches are a red flag that should prompt an immediate tow or a cautious drive to a repair facility rather than continuing to drive under the assumption that a fluid top-up will solve the problem.

If the fluid and leak checks come up negative and the level remains stable, the issue may lie with a sensor or control module. In such cases, the service brake warning may still indicate a potential problem worth addressing promptly, because electronic faults can mask a mechanical problem or degrade the performance of ABS and stability systems when they are most needed. A professional diagnostic can read the fault codes from the truck’s computer. These codes pinpoint the area of concern, whether it is a sensor, a wiring harness, a software fault, or a hydraulic component. The technician will check the master cylinder for internal leaks, inspect the ABS sensors and tone rings on the wheels, verify brake pad wear indicators, and test the system under controlled conditions to confirm the behavior of the hydraulic circuit and the anti-lock function.

Understanding the distinction between a likely fluid issue and a potential mechanical or electronic fault can help you communicate more effectively with a technician. A practical approach is to describe what you observed just before the warning appeared: the pedal feel, any unusual noises, whether there was a change in braking distance, and whether you noticed the ABS pulsing when braking. This information, combined with the vehicle’s history, can guide a technician toward a faster, more accurate diagnosis. It is worth noting that the specifics of how a Truck or light-duty vehicle reports brake-system problems can vary by make and model. Some trucks will illuminate a dedicated brake-warning light, while others use the same light for both low-fluid and system faults. Either way, the essential principle holds: the warning is a safety signal that should be treated as a call to action rather than a suggestion to continue driving.

Given the stakes, many maintenance professionals emphasize the value of preventive maintenance and timely education about brake-system health. When you prepare to navigate this issue, consider integrating maintenance practices that keep the system in good shape and reduce the frequency of warnings. Regular checks of the brake fluid level and condition should be part of a routine before long trips or heavy-haul operations. Inspecting brake lines and hoses for signs of wear or leaking, especially in areas exposed to heat and road debris, is another key step. If you are responsible for a fleet, establishing a standardized inspection routine and ensuring that drivers know how to recognize early signs of brake-system trouble can dramatically improve safety and uptime. A structured approach to maintenance does not only protect the driver; it protects the vehicle, other road users, and the investment you have made in keeping essential service payloads moving reliably.

As you consider the path forward after seeing the Service Brake System warning, think of it as a vital safety sentinel rather than a nuisance signal. This mindset makes it easier to approach the repair process with urgency and calm. You might be tempted to interpret the warning through the lens of convenience—after all, a long drive or a tight schedule can tempt you to postpone a diagnostic. The reality, however, is that the longer you drive with a compromised braking system, the greater the risk of reduced stopping power, longer stopping distances, or, in the worst-case scenario, brake failure. The human factors at play include brake performance that changes with temperature, load, and road conditions. For example, a rotor that warps with heat during a mountain descent may respond differently after a period of cooling. A fluid that has absorbed air during a leak or during maintenance work can behave erratically when heat builds again. The unpredictable nature of these interactions is why the best practice is to treat the warning as a serious signal and to arrange for a professional assessment before resuming normal service.

If you want to learn more about how professionals approach brake-system maintenance in practical settings, there is value in looking at broader maintenance frameworks. Hands-on training and practical guidelines help technicians diagnose and fix issues efficiently and safely. For those seeking a more formal, plant-level perspective on truck maintenance, there are resources focusing on the importance of ongoing training and structured maintenance programs. This context can illuminate why a relatively small anomaly in a vehicle’s behavior—like a faint vibration during braking or a minor wobble in the steering wheel—may be a symptom of a larger system issue, one that demands careful inspection and methodical repair rather than quick fixes. In many cases, adopting a disciplined approach to brake-system maintenance pays dividends in uptime, safety, and the confidence of the driver who relies on dependable braking in demanding environments.

Ultimately, the Service Brake System warning is a driver’s prompt to pause, assess, and engage the right expertise. It operates at the intersection of mechanical integrity and electronic intelligence, reminding us that safety in heavy-duty contexts depends on respect for the limits of the machine and the foresight to protect it with thoughtful maintenance. If you are curious about how such maintenance practices translate into real-world readiness, you can explore related discussions and case studies in practical maintenance resources that emphasize hands-on training and fleet efficiency. For instance, you can refer to fire-truck-maintenance-training-importance to gain perspective on how systematic upkeep translates into safer operation, longer component life, and steadier uptime across demanding service profiles. The lessons translate well to a wide range of trucks and configurations, underscoring a core principle: safety, reliability, and cost-effective operation stem from a proactive, informed approach to brake-system health.

In closing, while the circumstances surrounding a Service Brake System warning can vary—from a simple dip in brake-fluid level to a more complex ABS-related fault—the prudent driver treats it with the seriousness it deserves. A clear diagnosis, prompt maintenance, and adherence to safety practices are the trifecta that returns you to a road-ready, dependable braking system. Do not let the warning drift into the background while you push onward in the name of convenience. The right choice is a cautious, informed response that prioritizes safety and preserves braking performance for every mile ahead. External resources, such as official brake-system performance standards from authorities, provide additional context for understanding how these components are expected to perform under various conditions and loads. Reading these guidelines can deepen your appreciation for the design and testing behind the warnings you see and reinforce why a professional assessment is essential when the light comes on.

External resource: https://www.nhtsa.gov/vehicle/safety-standards/service-brake-system-performance-requirements-light-duty-truck

When the Truck Says Service Brake System: From Alarm to Action, Safety, and Compliance

The moment a truck sports a flashing or steady Service Brake System warning is rarely a moment of calm. For most drivers, the signal arrives with a mix of concern and urgency, a reminder that the stopping power of a vehicle is not a negotiable feature but a core safety function. This warning can show up in several forms on modern dashboards, but the meaning remains consistent: there is a problem with the braking system that could compromise your ability to stop safely. The consequences of ignoring it are not theoretical. Brakes are not a subsystem you can trust only when everything feels smooth. They operate under heavy loads, heat, and wear, and even small deviations can herald larger failures. The warning is not a suggestion; it is a call to assess, diagnose, and act. When you see it, you are asked to shift your attention from routine driving to a critical safety check that protects you, your cargo, other road users, and the integrity of regulations that govern commercial operations. It is a moment to switch from routine driving to informed, deliberate care, and that transition should begin the instant the light appears or, ideally, a moment sooner as part of a pre-trip safety mindset.

To understand why this warning arises and what to do next, it helps to think about brakes as a system rather than a single component. Brakes involve hydraulics or pneumatics, sensors, electronic control modules, and sometimes a dedicated anti-locking mechanism. They respond to pedal input with hydraulic pressure that clamps brake pads against rotors or drums, converting the kinetic energy of motion into heat and stopping power. In most trucks, these systems are designed with a buffer so that a failure in one part does not instantly yield total loss of braking, but it can still reduce stopping effectiveness dramatically. A warning lamp is the system’s way of telling you that one or more of its subsystems is not performing within safe limits. The path from warning to action is not a single move; it is a sequence that protects life and keeps you compliant with safety and transportation rules. The research and practical experience shared by technicians consistently emphasize that a warning is never merely cosmetic. It is a signal to slow down, assess, and seek professional help before continuing.

The causes behind a Service Brake System warning are varied enough that a driver might feel overwhelmed trying to sort them out on the fly. Yet most issues fall into a few practical categories that any driver can recognize with careful checking and a measured response. Low brake fluid level is one of the most common culprits. Fluid levels can fall as the brakes wear, or they can drop because of a leak in the lines, hoses, or master cylinder. Checking the brake fluid reservoir under the hood becomes the first diagnostic step for many drivers. If the level sits below the minimum mark, adding the correct type of fluid is a prudent move, but it is not a fix. Low fluid often signals an underlying problem that will continue to drain the system if left unaddressed. The presence of a leak, whether seen as a wet spot beneath the vehicle or a damp area along the brake lines, is a red flag that demands immediate attention. Leaks compromise hydraulic pressure and can lead to a sudden loss of braking capacity that can be catastrophic in traffic, especially on downhill grades or in urban environments with heavy stop-and-go traffic.

Another frequent cause is worn brake pads. Modern trucks commonly employ wear sensors embedded in the pads; when the pads thin to a certain thickness, the sensor triggers a warning that aligns with the brake system light. A companion symptom is a high-pitched squeal when you apply the brakes, which is the sensor calling attention to pad wear. If you ignore this, you risk grinding the pad-metal into the rotor, which escalates wear, reduces braking efficiency, and invites more serious repairs. A third common issue involves the actual brake components—calipers, rotors, and the master cylinder—where wear, corrosion, or misalignment can create an imperfect seal, increased pedal travel, or inconsistent braking feel. Even when the vehicle seems to slow down normally, subtle changes in pedal feel, a spongy or soft sensation, or uneven braking between the front and rear axles can indicate an emerging fault that should not be dismissed as a normal variation.

A related category involves the anti-lock braking system itself. ABS errors can illuminate the warning light because the control module detects a fault in the sensors or the circuitry that governs wheel speed data. In some cases, the brakes work as a conventional system, but the ABS warning indicates the computer has detected an anomaly that could affect controlled braking under slippery or emergency conditions. Electrical faults—short circuits, faulty wiring, or failed sensors—can also trigger the warning by sending erroneous information to the vehicle’s computer. The common thread across these scenarios is that a single root cause can cascade into multiple symptoms, masking the actual issue behind a general warning. This is why a diagnostic approach that goes beyond surface-level checks is essential. A mechanic will typically use an OBD-II scanner to pull fault codes stored in the vehicle’s computer, which point to specific subsystems, sensors, or circuits involved. These codes do not replace physical inspection; they guide technicians to the probable origin of the fault and help tailor the repair to the exact fault mode. The synergy between diagnostic scanning and hands-on inspection is what ensures that the remedy matches the risk.

From a safety perspective, the moment a Service Brake System warning appears, the prudent course is to moderate driving behavior and prepare for a careful, thorough evaluation. Do not press your luck by testing the system at highway speeds or in heavy traffic. The loss of braking power, even for a moment, can have cascading consequences—longer stopping distances, the risk of skidding on wet or slippery pavement, or inadvertent locking of wheels in a situation requiring precise modulation of pressure. The guidance from technicians with ASE credentials is clear: assess, don’t guess. A professional diagnosis is essential because the issue may reside in the hydraulic or electronic architecture rather than in a single component that can be replaced. The importance of this approach extends beyond the vehicle. For commercial fleets, ignoring a warning can lead to violations of Department of Transportation regulations, which have real consequences for fleet operations, insurance, and the company’s standing with regulatory bodies. Maintaining a proactive safety culture around brake system checks is not only responsible but also a hallmark of professional fleet management.

As the conversation about brake systems deepens, it is useful to recognize how different subsystems interact. The hydraulic portion of a typical truck brake system relies on a reservoir, lines, master cylinder, wheel cylinders or calipers, and the brake pads or shoes. When you depress the pedal, pressure builds in the hydraulic lines, forcing the pads against the rotors or drums. The resulting friction generates heat, which must be dissipated by the braking system and, on long descents, by the vehicle’s cooling mechanisms and, in some designs, exhaust brakes or other supplementary devices. The interplay between hydraulic pressure and electronic controls adds a layer of complexity. In ABS-equipped systems, the computer monitors wheel speed sensors at each wheel. If a wheel begins to lock up, the system modulates brake pressure to prevent skidding. If the sensors or module misbehave, the computer can see an anomaly even if the mechanical brakes are functioning. This is why a driver might notice the ABS light illuminate alongside the brake warning and why both symptoms deserve prompt attention. The presence of an ABS fault often indicates that the problem is not just a mechanical issue but a control system issue that could complicate emergency braking and stability in adverse conditions. The diagnostic approach, therefore, must consider both hydraulics and electronics, and the technician’s toolkit will typically include a pressure gauge, a visual inspection of lines and fittings for leaks or damage, a check of sensor wiring, and a code readout that helps identify the electrical fault or sensor drift.

In the broader context of maintenance and safety culture, the warning also invites reflection on routine preventive care. Brake fluid is not a one-size-fits-all substance; the vehicle manual specifies the correct type and the interval at which fluid should be replaced. Fluid quality degrades with time and exposure to heat, moisture, and contaminants. When the level is checked, the color and clarity can tell a story: clear or amber fluid is typical; a dark or contaminated fluid signals a need for replacement and possibly complete hydraulic system flushing. Routine checks for fluid level, leaks, and pad wear should be standard practice, not a reactionary measure. Some fleets implement a quarterly or semiannual brake inspection as part of a broader preventive maintenance schedule. This may include not just a visual inspection but also a more thorough analysis of braking performance on a test rig or road cycle, ensuring that the system retains adequate hydraulic pressure, pad integrity, rotor or drum condition, and sensor function. Such proactive steps reduce the risk of unexpected failures and keep the fleet compliant with regulatory expectations.

The decision to act on a brake warning is not solely a matter of personal safety; it is a matter of operational discipline. In commercial settings, documentation matters. Maintaining a record of inspections, fluid top-ups, pad replacements, and diagnostic findings helps fleets demonstrate ongoing compliance during inspections and audits. A well-documented maintenance history can also help managers spot patterns that might indicate systemic issues, such as recurring leaks in a particular line or abnormal wear on a specific axle. This information supports proactive scheduling of repairs, supplier coordination, and budget planning. It also reinforces a safety-first mindset among operators, who learn to value the warning not as an inconvenience but as a protective signal that can prevent accidents and costly downtime.

For operators and fleet managers who are seeking to translate theory into practice, the pathway from warning to safe operation begins with a disciplined response. First, the moment the warning appears, the driver should move to a safe location as soon as possible and avoid continuing to drive under the warning if there are signs of compromised braking, such as a soft or spongy pedal, reduced braking power, or unusual noise. Once safely parked, a systematic evaluation follows: check the brake fluid level and top up if appropriate, inspect for obvious leaks or damage, and listen for unusual sounds that might indicate rotor or pad concerns. If fluid levels are low, the suspicion is a leak that must be investigated; if there is no visible leakage but the fluid is low, the system could have a slow leak or an internal fault. In either case, professional diagnosis is essential. A technician will typically perform a diagnostic scan to pull fault codes, check for ABS-related faults, inspect the hydraulic system for pressure integrity, and physically examine pads, rotors, and calipers. Each step narrows the field of potential problems and guides the repair plan. The end goal is a return to normal braking performance with confidence that both the driver and the vehicle meet safety and regulatory expectations.

For teams that rely on continuous learning and consistent maintenance, there is value in structured training that emphasizes brake system fundamentals, inspection techniques, and the interpretation of diagnostic codes. Engaging with ongoing training resources, including targeted maintenance programs, reinforces best practices and helps prevent the common missteps that lead to unnecessary downtime. A practical reminder is that even when the truck seems to operate normally, hidden issues like a dragging brake or slow-leak conditions can escalate quickly under heavy use or long descents. The safety margin eroded by neglect can translate into longer stopping distances, unpredictable pedal feel, and greater risk in adverse conditions. The takeaway is clear: the Service Brake System warning is a critical signal that demands careful, informed action and a rigorous commitment to maintenance discipline. This discipline is the American road safety standard as much as it is a compliance requirement, ensuring that the truck, its operator, and the fleet remain within the boundaries of safety expectations and legal obligations.

In practical terms, the diagnostic process is rarely about a single fix. It is a process of ruling out possibilities, confirming the root cause, and performing the repair with attention to how the system behaves after the fix. If a brake fluid leak is found, it is not enough to simply fill the reservoir; the leak must be repaired, the system bled to remove air, and the fluid replaced with the correct specification. If wear is detected in pads or rotors, replacement and proper bed-in procedures are necessary to restore performance and longevity. If an ABS sensor or control module fault is identified, a software update, sensor replacement, or module recalibration may be required, along with a careful verification of wheel speed data and stability performance in various conditions. The sequencing of these steps matters because each repair affects another subsystem. For example, changing a brake hose may alter pressure dynamics, which in turn can influence rotor heat management or pad wear. Thorough testing after repairs—both on-road and on a diagnostic bench—helps ensure that the problem is truly resolved and that no new fault codes appear. This iteration embodies the principle that brake system maintenance is an integrated, not isolated, activity.

The discussion would be incomplete without noting the variations across different truck designs. Hydraulic braking systems, pneumatically assisted setups, and hybrid configurations each present unique maintenance challenges. Some trucks incorporate hydraulic exhaust braking, a feature that uses hydraulic pressure to improve slow-speed control on long descents and in severe braking scenarios. While highly effective, these systems demand precise hydraulic pressure management and routine checks of lines, seals, and control logic. A failure mode in such systems can manifest as diminished brake response, a lingering burning odor, or a gradual degradation of downhill control. Understanding these design differences helps crews anticipate what to look for during inspections and explains why a generic approach to brakes rarely suffices. It further underscores the value of specialized maintenance training that equips technicians to recognize the telltale signs of fatigue, misalignment, or hydraulic deterioration in complex braking architectures.

Throughout this chapter, the emphasis remains on turning the warning into an opportunity for safer operation and better compliance. It is about developing a mindset that treats brake checks as routine, not reactive. The service brake warning is a safeguard against complacency. It invites real-world action: stop safely, verify fluid levels and leaks, inspect physical components, consider the ABS status, and pursue a professional diagnostic path that reads the vehicle’s fault codes and translates them into a concrete repair plan. In commercial driving, where the consequences of failure extend beyond a single trip, this approach protects lives, preserves cargo, and maintains the fleet’s integrity in the eyes of regulators and customers alike. The combination of careful observation, methodical diagnostics, and timely repairs creates a resilient brake system that supports steady, safer operation, whether the truck is navigating city streets, winding mountain grades, or long-haul corridors.

For readers who want to link theory with hands-on practice in a classroom or shop setting, there is value in structured resources that translate brake system theory into actionable skills. A dedicated training resource like fire-truck maintenance service training can provide scenario-based guidance on brake inspections, sensor checks, and system bleeding procedures, helping teams standardize their approach and share best practices across the fleet. This kind of learning supports better communication between drivers and technicians and reduces the chance that a warning is misinterpreted or mishandled. It also reinforces the discipline of logging maintenance actions, which serves both safety and regulatory purposes. As a driver gathers experience with the warning, the steps become more instinctive: observe carefully, verify systematically, and treat any anomaly as a potential fault that deserves professional attention rather than a temporary nuisance to be ignored.

The overarching message, reinforced by safety organizations and professional technicians, is consistent: never delay addressing a Service Brake System warning. The driver’s ability to stop, steer, and respond to emergencies is the baseline of road safety. The consequences of a delayed reply can be severe, including reduced stopping power, longer braking distances, or loss of braking control in challenging driving conditions. In the best-case scenario, a warning prompts a straightforward fluid check and a cost-effective pad replacement. In the worst case, it uncovers a deeper hydraulic or electronic fault that could require more extensive repairs. Either way, the proactive path—pull over safely, inspect, diagnose, and repair with professional support—protects lives, protects cargo, and protects the integrity of the fleet’s operations. The guidance here aligns with the ethos of professional trucking: safety is not a luxury but a foundational requirement, and compliance follows from consistent, informed practice. By treating the Service Brake System warning as a warning with purpose rather than a nuisance, drivers and fleets alike create a culture of reliability that translates into safer roads and more efficient operations.

As you consider the road ahead, remember that safety and compliance are not mutually exclusive goals. They reinforce each other when approached with method and care. If you are part of a team that travels long miles or operates in challenging terrain, consistent maintenance practices, supported by ongoing training and meticulous record-keeping, can transform a moment of warning into a routine safeguard that never feels optional. When it comes to brakes, there is no shortcut. The chapters of knowledge and practice surrounding braking systems converge in a simple truth: respect the warning, protect the road, and pursue repair with deliberate precision. The long-term payoff is not just a smoother ride or a quieter dashboard. It is the confidence that comes from knowing your truck can stop when it matters most, every time you press the pedal.

To further empower ongoing learning and practice, consider engaging with maintenance resources that emphasize hands-on skills and system-level thinking. This kind of resource supports crews in translating diagnostic codes into concrete repair steps, aligns with the warning’s intent to prevent accidents, and helps maintain regulatory compliance. When drivers and technicians work from a shared playbook, the likelihood of misdiagnosis diminishes, and the speed of response improves. The Service Brake System warning, while initially unsettling, can thus become a catalyst for heightened safety, better maintenance discipline, and stronger compliance records. It is a signal that the system is doing its job: protecting life by prompting timely, informed action.

For readers seeking additional guidance or jurisdiction-specific requirements, the National Highway Traffic Safety Administration offers authoritative resources on brake system safety and inspection standards. See their general guidance at https://www.nhtsa.gov. In the meantime, the practical steps outlined here—pull over safely, inspect fluid levels and leaks, assess pads and rotors, consider ABS status, and seek a professional diagnosis—provide a reliable blueprint for turning alarm into assurance. And for teams looking to embed this practice into daily routines, linking to practical maintenance training resources can help standardize the process, ensuring that every crew member understands not only what to check but how to communicate findings and plan repairs within the larger framework of safety and compliance. By viewing the brake warning as a cue to action rather than a nuisance, you adopt a core principle of responsible trucking: safety first, every mile, every day.

Reference: authoritative guidance on brake system diagnostics and maintenance is available through official resources from automotive safety organizations such as NHTSA. See the external link for more information: https://www.nhtsa.gov

Internal resource for team training: for ongoing maintenance education and standardized procedures, teams can explore structured programs such as fire-truck maintenance service training, which offers scenario-based guidance on brake inspections and service procedures. This resource can help fleets build consistent, repeatable practices across technicians and drivers, reducing the risk of misdiagnosis and improving overall brake reliability. Learn more about training opportunities at fire-truck maintenance service training.

Final thoughts

Recognizing and responding to the ‘Service Brake System’ warning light is imperative for every truck driver and fleet manager. Ignoring this critical alert can lead to catastrophic consequences, including brake failure. By understanding the mechanisms behind these warnings, diagnosing common issues, and taking immediate actions, you can safeguard not just your vehicle’s reliability but also your safety on the road. A proactive approach is not just better for compliance; it’s essential for protecting lives.